Page 50: of Offshore Engineer Magazine (May/Jun 2015)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2015 Offshore Engineer Magazine

Drilling

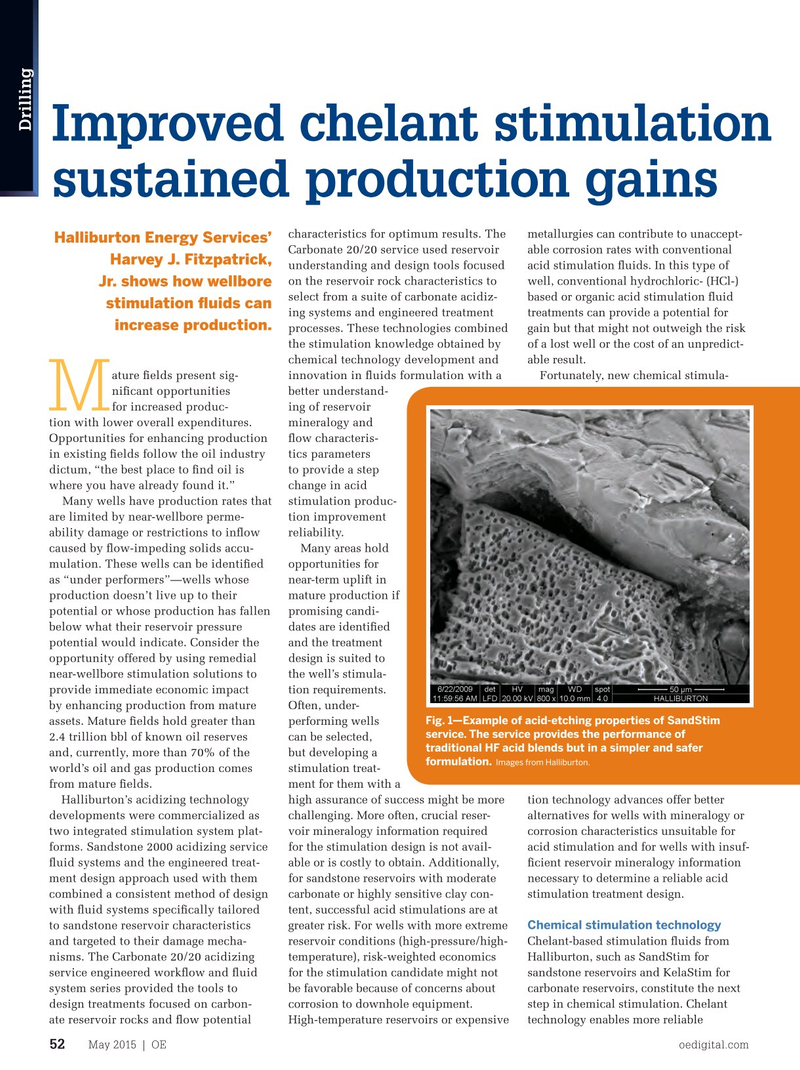

Improved chelant stimulation treatments deliver sustained production results but requires less complexity in fuid selection and sustained production gains treatment design compared to acid-based fuids (Figure 1). Technology built into metallurgies can contribute to unaccept- characteristics for optimum results. The Halliburton’s chelant stimulation fuids

Halliburton Energy Services’ able corrosion rates with conventional Carbonate 20/20 service used reservoir enables optimized treatments for a broad

Harvey J. Fitzpatrick, acid stimulation fuids. In this type of understanding and design tools focused range of reservoir and well characteris- well, conventional hydrochloric- (HCl-) on the reservoir rock characteristics to tics. Treatment design is less complex

Jr. shows how wellbore based or organic acid stimulation fuid select from a suite of carbonate acidiz- because chelant technology accommo- stimulation fuids can treatments can provide a potential for ing systems and engineered treatment dates a broad range of mineralogy. The increase production.

gain but that might not outweigh the risk processes. These technologies combined risk of collateral damage from spent fuid of a lost well or the cost of an unpredict- the stimulation knowledge obtained by is signifcantly lower than from acid- able result. chemical technology development and based treatments (Figure 2). Successful ature felds present sig- Fortunately, new chemical stimula- innovation in fuids formulation with a stimulation is achieved more reliably. nifcant opportunities better understand-

M for increased produc- ing of reservoir tion with lower overall expenditures. mineralogy and

Opportunities for enhancing production fow characteris- in existing felds follow the oil industry tics parameters dictum, “the best place to fnd oil is to provide a step where you have already found it.” change in acid Many wells have production rates that stimulation produc- are limited by near-wellbore perme- tion improvement ability damage or restrictions to infow reliability.

caused by fow-impeding solids accu- Many areas hold mulation. These wells can be identifed opportunities for as “under performers”—wells whose near-term uplift in production doesn’t live up to their mature production if potential or whose production has fallen promising candi- below what their reservoir pressure dates are identifed potential would indicate. Consider the and the treatment opportunity offered by using remedial design is suited to near-wellbore stimulation solutions to the well’s stimula- provide immediate economic impact tion requirements. by enhancing production from mature Often, under-

Fig. 1—Example of acid-etching properties of SandStim assets. Mature felds hold greater than performing wells service. The service provides the performance of 2.4 trillion bbl of known oil reserves can be selected, traditional HF acid blends but in a simpler and safer and, currently, more than 70% of the but developing a formulation. Images from Halliburton.

world’s oil and gas production comes stimulation treat- from mature felds. ment for them with a

Halliburton’s acidizing technology tion technology advances offer better high assurance of success might be more Hazards associated with reservoir dam- developments were commercialized as alternatives for wells with mineralogy or challenging. More often, crucial reser- age, tubular and well equipment corro- two integrated stimulation system plat- corrosion characteristics unsuitable for voir mineralogy information required sion, and health, safety, and environment forms. Sandstone 2000 acidizing service acid stimulation and for wells with insuf- for the stimulation design is not avail- (HSE) concerns can be signifcantly fuid systems and the engineered treat- fcient reservoir mineralogy information able or is costly to obtain. Additionally, reduced. Successful results are obtained ment design approach used with them necessary to determine a reliable acid for sandstone reservoirs with moderate with greater reliability. Chelant stimula- combined a consistent method of design stimulation treatment design. carbonate or highly sensitive clay con- tion fuid systems provide the following with fuid systems specifcally tailored tent, successful acid stimulations are at benefts:

Chemical stimulation technology • to sandstone reservoir characteristics greater risk. For wells with more extreme Treatment design is simplifed. Chelant and targeted to their damage mecha- Chelant-based stimulation fuids from reservoir conditions (high-pressure/high- stimulation technology helps reduce nisms. The Carbonate 20/20 acidizing Halliburton, such as SandStim for temperature), risk-weighted economics risks of concurrent treatment damage service engineered workfow and fuid sandstone reservoirs and KelaStim for for the stimulation candidate might not with solubility control for spent-treat- system series provided the tools to carbonate reservoirs, constitute the next be favorable because of concerns about ment fuid.

• design treatments focused on carbon- step in chemical stimulation. Chelant corrosion to downhole equipment. Potential damage can be minimized ate reservoir rocks and fow potential technology enables more reliable High-temperature reservoirs or expensive when stimulating formations of uncertain

May 2015 | OE oedigital.com 52 052_OE0515_D&C1_Halliburton.indd 52 4/20/15 3:18 PM

49

49

51

51