Page 58: of Offshore Engineer Magazine (May/Jun 2015)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2015 Offshore Engineer Magazine

reactive as addi-reactive as addi- tion of solids with tion of solids with no prior planning no prior planning can cause addi-can cause addi- tional problems tional problems and even invoke and even invoke reservoir damage. reservoir damage.

While these typi-While these typi- cal bridging solids cal bridging solids are available in a are available in a variety of grades variety of grades there are relatively there are relatively new materials new materials that may provide that may provide advantages for advantages for

CHAIN STOPPERS CHAIN STOPPERS these deepwater these deepwater prospects:prospects:

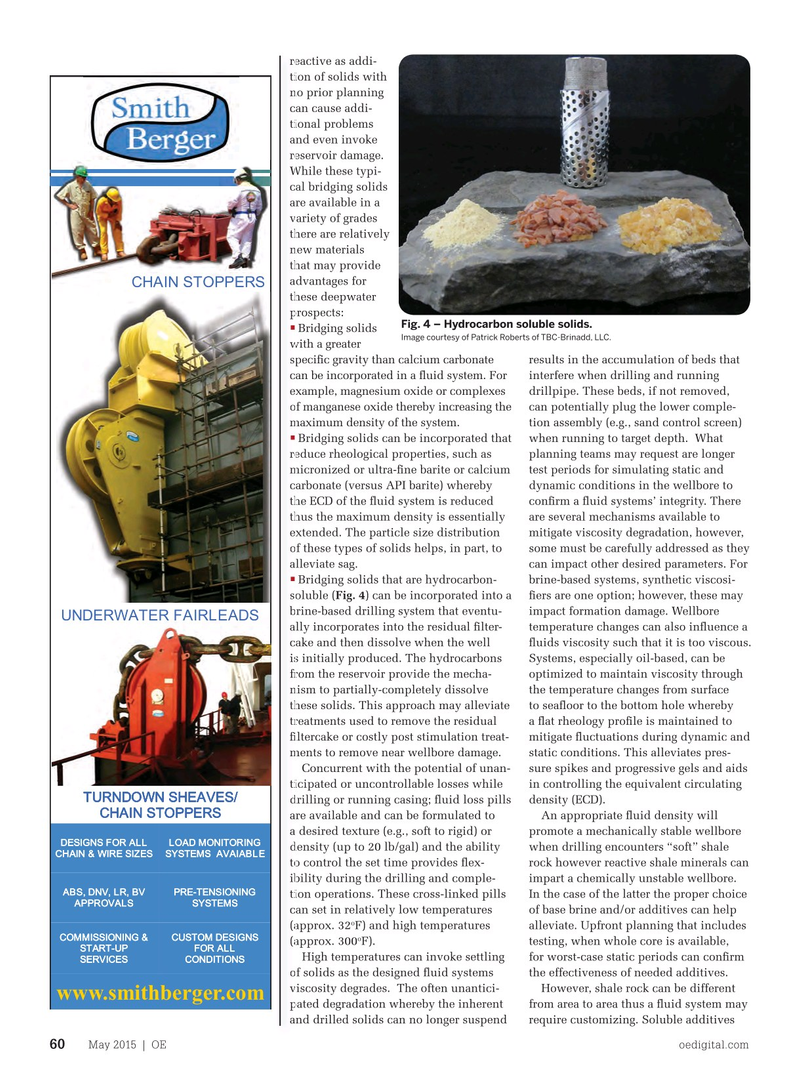

Fig. 4 – Hydrocarbon soluble solids.

•• Bridging solids

Image courtesy of Patrick Roberts of TBC-Brinadd, LLC.

with a greater with a greater speci? c gravity than calcium carbonate speci? c gravity than calcium carbonate results in the accumulation of beds that can be incorporated in a ? uid system. For can be incorporated in a ? uid system. For interfere when drilling and running example, magnesium oxide or complexes example, magnesium oxide or complexes drillpipe. These beds, if not removed, of manganese oxide thereby increasing the of manganese oxide thereby increasing the can potentially plug the lower comple- maximum density of the system. maximum density of the system. tion assembly (e.g., sand control screen) • •

Bridging solids can be incorporated that when running to target depth. What reduce rheological properties, such as reduce rheological properties, such as planning teams may request are longer micronized or ultra-? ne barite or calcium micronized or ultra-? ne barite or calcium test periods for simulating static and carbonate (versus API barite) whereby carbonate (versus API barite) whereby dynamic conditions in the wellbore to the ECD of the ? uid system is reduced the ECD of the ? uid system is reduced con? rm a ? uid systems’ integrity. There thus the maximum density is essentially thus the maximum density is essentially are several mechanisms available to extended. The particle size distribution extended. The particle size distribution mitigate viscosity degradation, however, of these types of solids helps, in part, to of these types of solids helps, in part, to some must be carefully addressed as they alleviate sag. alleviate sag. can impact other desired parameters. For ••

Bridging solids that are hydrocarbon- brine-based systems, synthetic viscosi- soluble ( soluble (Fig. 4) can be incorporated into a ? ers are one option; however, these may brine-based drilling system that eventu- brine-based drilling system that eventu- impact formation damage. Wellbore

UNDERWATER FAIRLEADS UNDERWATER FAIRLEADS ally incorporates into the residual ? lter- ally incorporates into the residual ? lter- temperature changes can also in? uence a cake and then dissolve when the well cake and then dissolve when the well ? uids viscosity such that it is too viscous. is initially produced. The hydrocarbons is initially produced. The hydrocarbons Systems, especially oil-based, can be from the reservoir provide the mecha- from the reservoir provide the mecha- optimized to maintain viscosity through nism to partially-completely dissolve nism to partially-completely dissolve the temperature changes from surface these solids. This approach may alleviate these solids. This approach may alleviate to sea? oor to the bottom hole whereby treatments used to remove the residual treatments used to remove the residual a ? at rheology pro? le is maintained to ? ltercake or costly post stimulation treat- ? ltercake or costly post stimulation treat- mitigate ? uctuations during dynamic and ments to remove near wellbore damage. ments to remove near wellbore damage. static conditions. This alleviates pres-

Concurrent with the potential of unan- sure spikes and progressive gels and aids ticipated or uncontrollable losses while ticipated or uncontrollable losses while in controlling the equivalent circulating

TURNDOWN SHEAVES/ drilling or running casing; ? uid loss pills drilling or running casing; ? uid loss pills density (ECD).

CHAIN STOPPERS are available and can be formulated to are available and can be formulated to

An appropriate ? uid density will a desired texture (e.g., soft to rigid) or a desired texture (e.g., soft to rigid) or promote a mechanically stable wellbore

DESIGNS FOR ALL LOAD MONITORING density (up to 20 lb/gal) and the ability density (up to 20 lb/gal) and the ability when drilling encounters “soft” shale

CHAIN & WIRE SIZES SYSTEMS AVAIABLE to control the set time provides ? ex-to control the set time provides ? ex- rock however reactive shale minerals can ibility during the drilling and comple-ibility during the drilling and comple- impart a chemically unstable wellbore.

ABS, DNV, LR, BV PRE-TENSIONING tion operations. These cross-linked pills tion operations. These cross-linked pills

In the case of the latter the proper choice

APPROVALS SYSTEMS can set in relatively low temperatures can set in relatively low temperatures of base brine and/or additives can help o (approx. 32 (approx. 32 F) and high temperatures alleviate. Upfront planning that includes

COMMISSIONING & CUSTOM DESIGNS o (approx. 300 (approx. 300 F).

testing, when whole core is available,

START-UP FOR ALL

High temperatures can invoke settling for worst-case static periods can con? rm

SERVICES CONDITIONS of solids as the designed ? uid systems of solids as the designed ? uid systems the effectiveness of needed additives. viscosity degrades. The often unantici- viscosity degrades. The often unantici- However, shale rock can be different www.smithberger.com pated degradation whereby the inherent pated degradation whereby the inherent from area to area thus a ? uid system may and drilled solids can no longer suspend and drilled solids can no longer suspend require customizing. Soluble additives

May 2015 | OE oedigital.com 60 056_OE0515_D&C2_TexasBrine.indd 60 4/20/15 6:35 PM

57

57

59

59