Page 46: of Offshore Engineer Magazine (Sep/Oct 2015)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2015 Offshore Engineer Magazine

the amount of drilling required to reach the targets it wants to, saving the limited cash there is in the cur- rent environment. The scope had been 140, but that has so far been

Drilling reduced to 130, with prolonging the horizontal wells and geosteering, to target the sands, helping to more effciently drain reservoir targets.

Statoil also selected Schlumberger as the integrated drilling services contract provider on Mariner. Thom says this has reduced the number of contractor interfaces from more than 30 to just one.

“For us now, the focus is to standardize and not to change our plans,” Thom says. “We have frozen the well design, the casing program, completion design etc., and they will be kept until we get good at them. We want to learn, and we will have a lot of monitor-

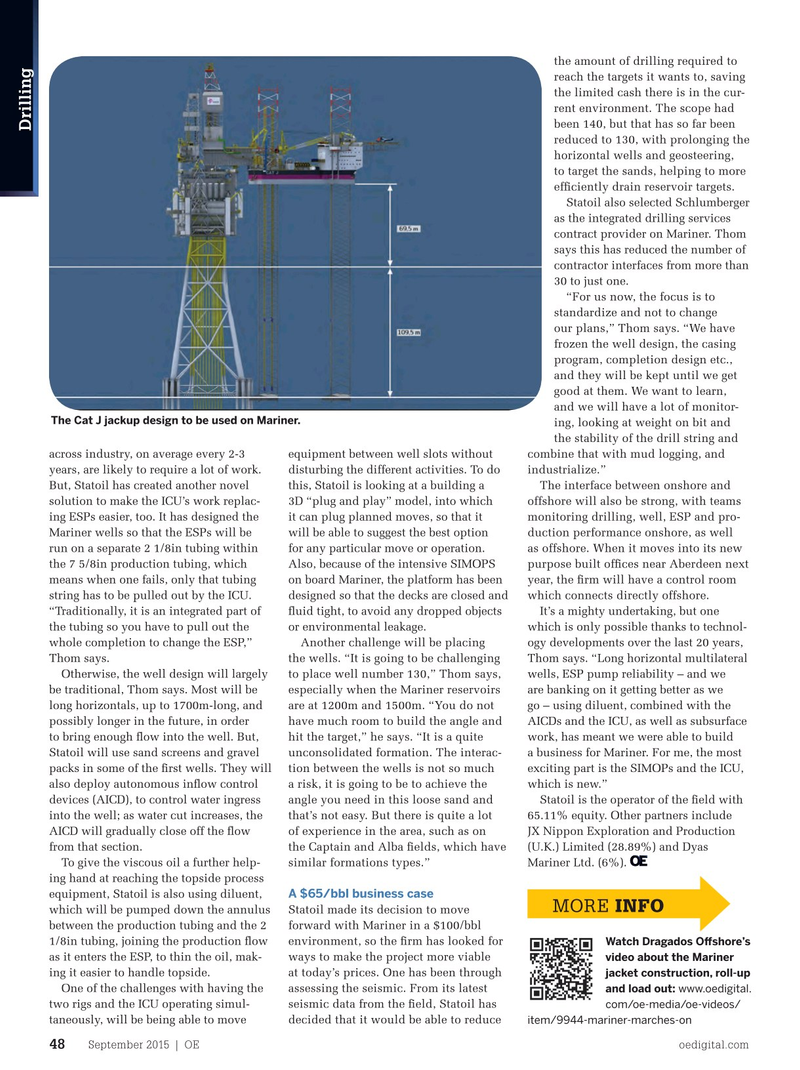

The Cat J jackup design to be used on Mariner. ing, looking at weight on bit and the stability of the drill string and across industry, on average every 2-3 equipment between well slots without combine that with mud logging, and years, are likely to require a lot of work. disturbing the different activities. To do industrialize.”

But, Statoil has created another novel this, Statoil is looking at a building a The interface between onshore and solution to make the ICU’s work replac- 3D “plug and play” model, into which offshore will also be strong, with teams ing ESPs easier, too. It has designed the it can plug planned moves, so that it monitoring drilling, well, ESP and pro-

Mariner wells so that the ESPs will be will be able to suggest the best option duction performance onshore, as well run on a separate 2 1/8in tubing within for any particular move or operation. as offshore. When it moves into its new the 7 5/8in production tubing, which Also, because of the intensive SIMOPS purpose built offces near Aberdeen next means when one fails, only that tubing on board Mariner, the platform has been year, the frm will have a control room string has to be pulled out by the ICU. designed so that the decks are closed and which connects directly offshore.

“Traditionally, it is an integrated part of fuid tight, to avoid any dropped objects It’s a mighty undertaking, but one the tubing so you have to pull out the or environmental leakage. which is only possible thanks to technol- whole completion to change the ESP,” Another challenge will be placing ogy developments over the last 20 years,

Thom says. the wells. “It is going to be challenging Thom says. “Long horizontal multilateral

Otherwise, the well design will largely to place well number 130,” Thom says, wells, ESP pump reliability – and we be traditional, Thom says. Most will be especially when the Mariner reservoirs are banking on it getting better as we long horizontals, up to 1700m-long, and are at 1200m and 1500m. “You do not go – using diluent, combined with the possibly longer in the future, in order have much room to build the angle and AICDs and the ICU, as well as subsurface to bring enough fow into the well. But, hit the target,” he says. “It is a quite work, has meant we were able to build

Statoil will use sand screens and gravel unconsolidated formation. The interac- a business for Mariner. For me, the most packs in some of the frst wells. They will tion between the wells is not so much exciting part is the SIMOPs and the ICU, also deploy autonomous infow control a risk, it is going to be to achieve the which is new.” devices (AICD), to control water ingress angle you need in this loose sand and Statoil is the operator of the feld with into the well; as water cut increases, the that’s not easy. But there is quite a lot 65.11% equity. Other partners include

AICD will gradually close off the fow of experience in the area, such as on JX Nippon Exploration and Production from that section. the Captain and Alba felds, which have (U.K.) Limited (28.89%) and Dyas

To give the viscous oil a further help- similar formations types.” Mariner Ltd. (6%). ing hand at reaching the topside process

A $65/bbl business case equipment, Statoil is also using diluent,

MORE INFO which will be pumped down the annulus Statoil made its decision to move between the production tubing and the 2 forward with Mariner in a $100/bbl 1/8in tubing, joining the production fow environment, so the frm has looked for

Watch Dragados Ofshore’s as it enters the ESP, to thin the oil, mak- ways to make the project more viable video about the Mariner ing it easier to handle topside. at today’s prices. One has been through jacket construction, roll-up

One of the challenges with having the assessing the seismic. From its latest and load out: www.oedigital.

two rigs and the ICU operating simul- seismic data from the feld, Statoil has com/oe-media/oe-videos/ taneously, will be being able to move decided that it would be able to reduce item/9944-mariner-marches-on

September 2015 | OE oedigital.com 48 046_OE0915_D&C1_Mariner.indd 48 8/19/15 10:39 PM

45

45

47

47