Page 55: of Offshore Engineer Magazine (Sep/Oct 2015)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2015 Offshore Engineer Magazine

pipeline fow may be set by a master

EPIC or supervisory control system. At each pump station, local controls work with the master set point to achieve the desired fow while working with pump specifc limits for suction and discharge pressure control.

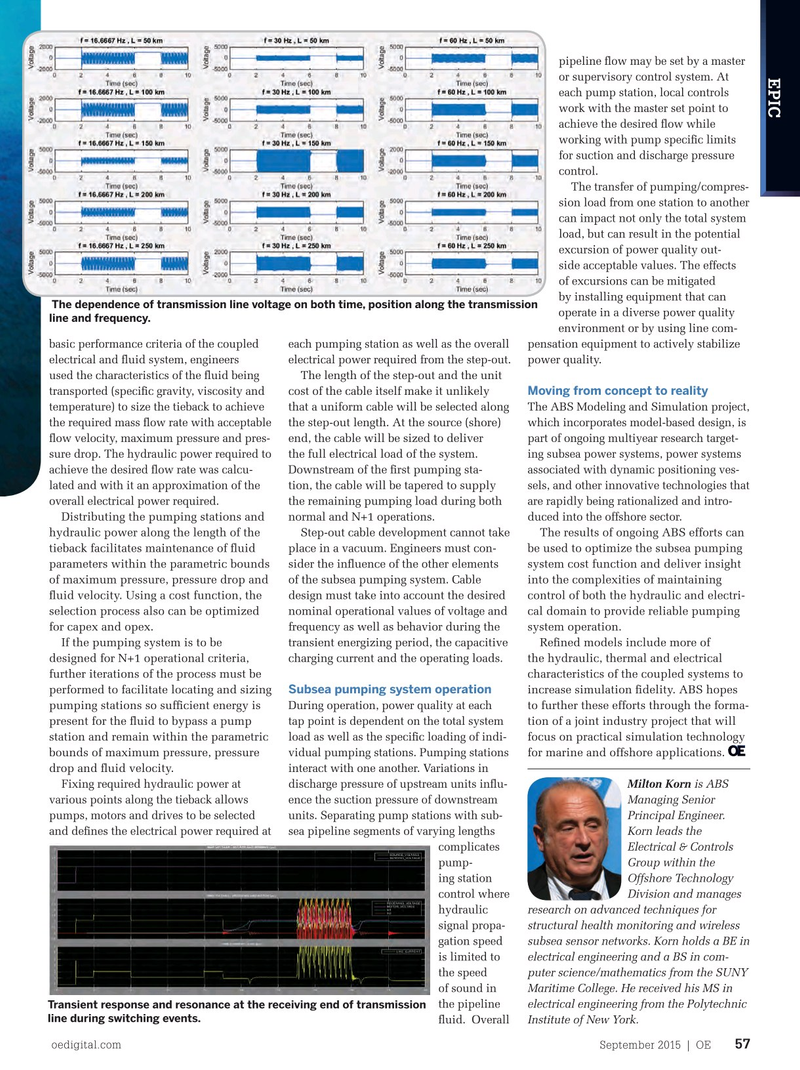

The transfer of pumping/compres- sion load from one station to another can impact not only the total system load, but can result in the potential excursion of power quality out- side acceptable values. The effects of excursions can be mitigated by installing equipment that can The dependence of transmission line voltage on both time, position along the transmission operate in a diverse power quality line and frequency.

environment or by using line com- basic performance criteria of the coupled each pumping station as well as the overall pensation equipment to actively stabilize electrical and fuid system, engineers electrical power required from the step-out. power quality.

The length of the step-out and the unit used the characteristics of the fuid being

Moving from concept to reality cost of the cable itself make it unlikely transported (specifc gravity, viscosity and that a uniform cable will be selected along temperature) to size the tieback to achieve The ABS Modeling and Simulation project, the step-out length. At the source (shore) the required mass fow rate with acceptable which incorporates model-based design, is end, the cable will be sized to deliver fow velocity, maximum pressure and pres- part of ongoing multiyear research target- the full electrical load of the system. sure drop. The hydraulic power required to ing subsea power systems, power systems

Downstream of the frst pumping sta- achieve the desired fow rate was calcu- associated with dynamic positioning ves- tion, the cable will be tapered to supply lated and with it an approximation of the sels, and other innovative technologies that the remaining pumping load during both overall electrical power required. are rapidly being rationalized and intro-

Distributing the pumping stations and normal and N+1 operations.

duced into the offshore sector.

hydraulic power along the length of the Step-out cable development cannot take The results of ongoing ABS efforts can tieback facilitates maintenance of fuid place in a vacuum. Engineers must con- be used to optimize the subsea pumping parameters within the parametric bounds sider the infuence of the other elements system cost function and deliver insight of maximum pressure, pressure drop and of the subsea pumping system. Cable into the complexities of maintaining fuid velocity. Using a cost function, the design must take into account the desired control of both the hydraulic and electri- selection process also can be optimized nominal operational values of voltage and cal domain to provide reliable pumping for capex and opex. frequency as well as behavior during the system operation.

If the pumping system is to be transient energizing period, the capacitive Refned models include more of designed for N+1 operational criteria, charging current and the operating loads. the hydraulic, thermal and electrical further iterations of the process must be characteristics of the coupled systems to

Subsea pumping system operation performed to facilitate locating and sizing increase simulation fdelity. ABS hopes

During operation, power quality at each pumping stations so suffcient energy is to further these efforts through the forma- tap point is dependent on the total system present for the fuid to bypass a pump tion of a joint industry project that will load as well as the specifc loading of indi- station and remain within the parametric focus on practical simulation technology vidual pumping stations. Pumping stations bounds of maximum pressure, pressure for marine and offshore applications. interact with one another. Variations in drop and fuid velocity.

Fixing required hydraulic power at discharge pressure of upstream units infu- Milton Korn is ABS various points along the tieback allows ence the suction pressure of downstream Managing Senior pumps, motors and drives to be selected units. Separating pump stations with sub- Principal Engineer. and defnes the electrical power required at sea pipeline segments of varying lengths Korn leads the complicates Electrical & Controls pump- Group within the ing station Offshore Technology control where Division and manages hydraulic research on advanced techniques for signal propa- structural health monitoring and wireless gation speed subsea sensor networks. Korn holds a BE in is limited to electrical engineering and a BS in com- the speed puter science/mathematics from the SUNY of sound in Maritime College. He received his MS in the pipeline electrical engineering from the Polytechnic

Transient response and resonance at the receiving end of transmission line during switching events.

fuid. Overall Institute of New York.

oedigital.com September 2015 | OE 57 056-OE0915_EPIC1_ABS.indd 57 8/19/15 6:39 PM

54

54

56

56