Page 70: of Offshore Engineer Magazine (Sep/Oct 2015)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2015 Offshore Engineer Magazine

IM programs, leaving a have to decide between gap in what is commonly decommissioning, life accepted as “best prac- extension or divest- tice.” The SEMS program ment. Not only is this

Subsea is required to be audited a complex decision,

Monitoring Risk within two years of the but it is one that many & KPIs Assesment initial implementation GoM engineering teams and at least once every are facing for the ? rst three years thereafter. time in their career.

The bene? t of an open New subsea tiebacks to speci? cation is that it existing platforms offer allows the operator to set an economical option

Anomaly

Integrity Subsea their own IM plans and for the operators in management plan IM priorities based on risks comparison to the instal- relevant to their system. lation of new structures,

There are many serial especially in the current number one designed ? nancial environment. equipment in use in the However, subsea tieback

GoM. The challenge is of new developments

Documen-

Fit for passing the required to the existing ? owline- tation service audit with little direction riser systems that are from the auditor. nearing their service life requires a life extension Clarus has supported future opportunities with the asset. An assessment. audits on behalf of oper- IM program does not have to be expen-

Con? dent decisions ators and can con? rm sive. Using the same ef? cient approach

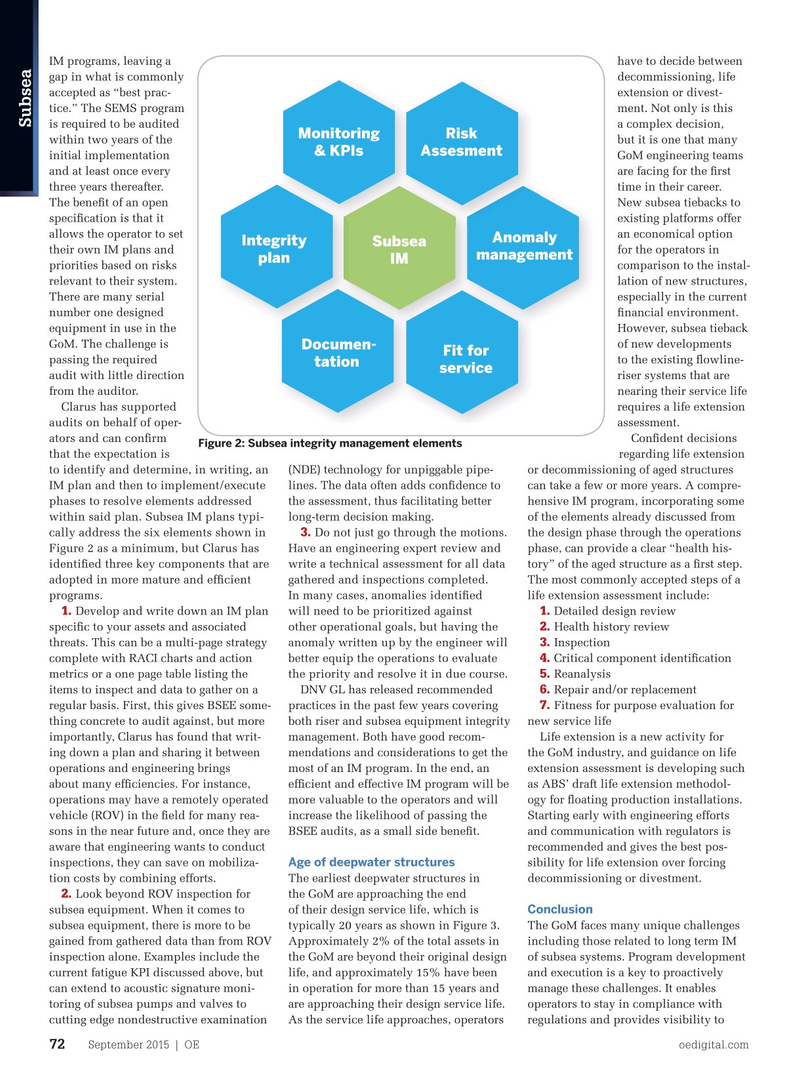

Figure 2: Subsea integrity management elements regarding life extension that the expectation is used to make this market a success can or decommissioning of aged structures (NDE) technology for unpiggable pipe- to identify and determine, in writing, an ensure that the GoM systems and the can take a few or more years. A compre- lines. The data often adds con? dence to IM plan and then to implement/execute people operating within those units are hensive IM program, incorporating some the assessment, thus facilitating better phases to resolve elements addressed safe. But, in order to do so, IM programs within said plan. Subsea IM plans typi- long-term decision making. of the elements already discussed from 3. cally address the six elements shown in Do not just go through the motions. the design phase through the operations

Figure 2 as a minimum, but Clarus has Have an engineering expert review and phase, can provide a clear “health his- identi? ed three key components that are write a technical assessment for all data tory” of the aged structure as a ? rst step. adopted in more mature and ef? cient gathered and inspections completed. The most commonly accepted steps of a programs. In many cases, anomalies identi? ed life extension assessment include:

Develop and write down an IM plan will need to be prioritized against Detailed design review 1. 1. 2. speci? c to your assets and associated other operational goals, but having the Health history review 3. threats. This can be a multi-page strategy anomaly written up by the engineer will Inspection 4. complete with RACI charts and action better equip the operations to evaluate Critical component identi? cation 5. metrics or a one page table listing the the priority and resolve it in due course. Reanalysis 6. items to inspect and data to gather on a DNV GL has released recommended Repair and/or replacement 7. regular basis. First, this gives BSEE some- practices in the past few years covering Fitness for purpose evaluation for thing concrete to audit against, but more both riser and subsea equipment integrity new service life importantly, Clarus has found that writ- management. Both have good recom- Life extension is a new activity for ing down a plan and sharing it between mendations and considerations to get the the GoM industry, and guidance on life operations and engineering brings most of an IM program. In the end, an extension assessment is developing such about many ef? ciencies. For instance, ef? cient and effective IM program will be as ABS’ draft life extension methodol-

THE PRODUCTS AND SOLUTIONS YOU NEED… WHEN YOU NEED THEM!

operations may have a remotely operated more valuable to the operators and will ogy for ? oating production installations. vehicle (ROV) in the ? eld for many rea- increase the likelihood of passing the Starting early with engineering efforts

W&O is one of the world’s largest suppliers of pipe, valves, fttings as well as actuation and engineered solutions. sons in the near future and, once they are BSEE audits, as a small side bene? t. and communication with regulators is

With over $42 million dollars of standing inventory across our worldwide network of strategically located branches aware that engineering wants to conduct recommended and gives the best pos- including locations in Houston, Houma, New Orleans, Mobile and Tampa—we have the Gulf of Mexico covered.

Age of deepwater structures inspections, they can save on mobiliza- sibility for life extension over forcing

W&O is your one stop source for pipe, piping systems, valves, fttings and omplex tion costs by combining efforts. The earliest deepwater structures in decommissioning or divestment. ™ engineered solutions including bulkhead sealing systems and Georg Fischer SeaCor , 2.

Look beyond ROV inspection for the GoM are approaching the end

USCG approved thermoplastic piping systems. Contact us today to learn more.

Conclusion subsea equipment. When it comes to of their design service life, which is subsea equipment, there is more to be typically 20 years as shown in Figure 3. The GoM faces many unique challenges 800.962.9696 • wosupply.com gained from gathered data than from ROV Approximately 2% of the total assets in including those related to long term IM inspection alone. Examples include the the GoM are beyond their original design of subsea systems. Program development current fatigue KPI discussed above, but life, and approximately 15% have been and execution is a key to proactively can extend to acoustic signature moni- in operation for more than 15 years and manage these challenges. It enables

Pipe | Valves | Fittings | Piping Systems | Engineered Solutions toring of subsea pumps and valves to are approaching their design service life. operators to stay in compliance with cutting edge nondestructive examination As the service life approaches, operators regulations and provides visibility to

September 2015 | OE oedigital.com 72 070_OE0915_Subsea2_Clarus.indd 72 8/19/15 6:32 PM

69

69

71

71