Page 46: of Offshore Engineer Magazine (Dec/Jan 2015)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2015 Offshore Engineer Magazine

Reliability

SAFETY

Subsea

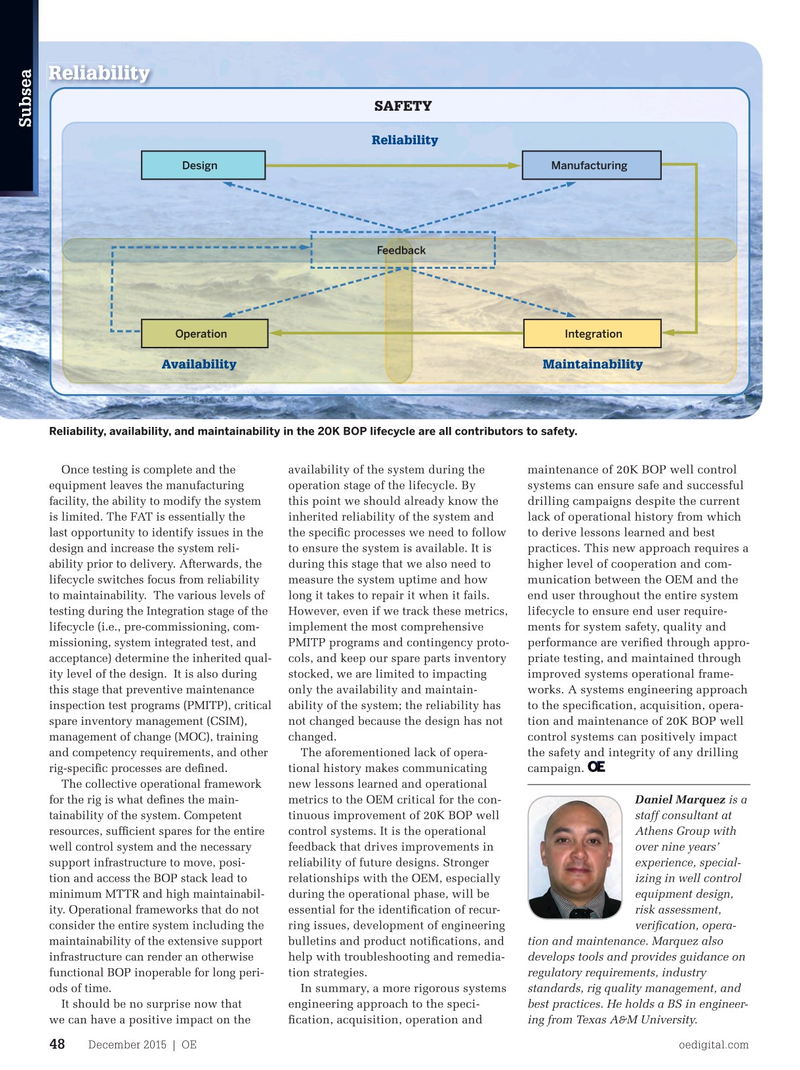

Reliability

Design Manufacturing

Feedback

Operation Integration

Availability Maintainability

Reliability, availability, and maintainability in the 20K BOP lifecycle are all contributors to safety.

Once testing is complete and the availability of the system during the maintenance of 20K BOP well control systems can ensure safe and successful equipment leaves the manufacturing operation stage of the lifecycle. By facility, the ability to modify the system this point we should already know the drilling campaigns despite the current lack of operational history from which is limited. The FAT is essentially the inherited reliability of the system and last opportunity to identify issues in the the speci? c processes we need to follow to derive lessons learned and best design and increase the system reli- to ensure the system is available. It is practices. This new approach requires a higher level of cooperation and com- ability prior to delivery. Afterwards, the during this stage that we also need to lifecycle switches focus from reliability measure the system uptime and how munication between the OEM and the to maintainability. The various levels of long it takes to repair it when it fails. end user throughout the entire system lifecycle to ensure end user require- testing during the Integration stage of the However, even if we track these metrics, lifecycle (i.e., pre-commissioning, com- implement the most comprehensive ments for system safety, quality and performance are veri? ed through appro- missioning, system integrated test, and PMITP programs and contingency proto- acceptance) determine the inherited qual- cols, and keep our spare parts inventory priate testing, and maintained through ity level of the design. It is also during stocked, we are limited to impacting improved systems operational frame- this stage that preventive maintenance only the availability and maintain- works. A systems engineering approach inspection test programs (PMITP), critical ability of the system; the reliability has to the speci? cation, acquisition, opera- spare inventory management (CSIM), not changed because the design has not tion and maintenance of 20K BOP well management of change (MOC), training changed. control systems can positively impact and competency requirements, and other The aforementioned lack of opera- the safety and integrity of any drilling campaign. rig-speci? c processes are de? ned. tional history makes communicating

The collective operational framework new lessons learned and operational for the rig is what de? nes the main- metrics to the OEM critical for the con- Daniel Marquez is a tainability of the system. Competent tinuous improvement of 20K BOP well staff consultant at resources, suf? cient spares for the entire control systems. It is the operational Athens Group with well control system and the necessary feedback that drives improvements in over nine years’ support infrastructure to move, posi- reliability of future designs. Stronger experience, special- tion and access the BOP stack lead to relationships with the OEM, especially izing in well control minimum MTTR and high maintainabil- during the operational phase, will be equipment design, ity. Operational frameworks that do not essential for the identi? cation of recur- risk assessment, consider the entire system including the ring issues, development of engineering veri? cation, opera- maintainability of the extensive support bulletins and product noti? cations, and tion and maintenance. Marquez also infrastructure can render an otherwise help with troubleshooting and remedia- develops tools and provides guidance on functional BOP inoperable for long peri- tion strategies. regulatory requirements, industry

In summary, a more rigorous systems ods of time. standards, rig quality management, and engineering approach to the speci-

It should be no surprise now that best practices. He holds a BS in engineer- ? cation, acquisition, operation and we can have a positive impact on the ing from Texas A&M University.

December 2015 | OE oedigital.com 48 046_OE1215_Subsea1_Athens.indd 48 11/20/15 6:05 PM

45

45

47

47