Page 17: of Offshore Engineer Magazine (Aug/Sep 2016)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2016 Offshore Engineer Magazine

FIELD OF VIEW

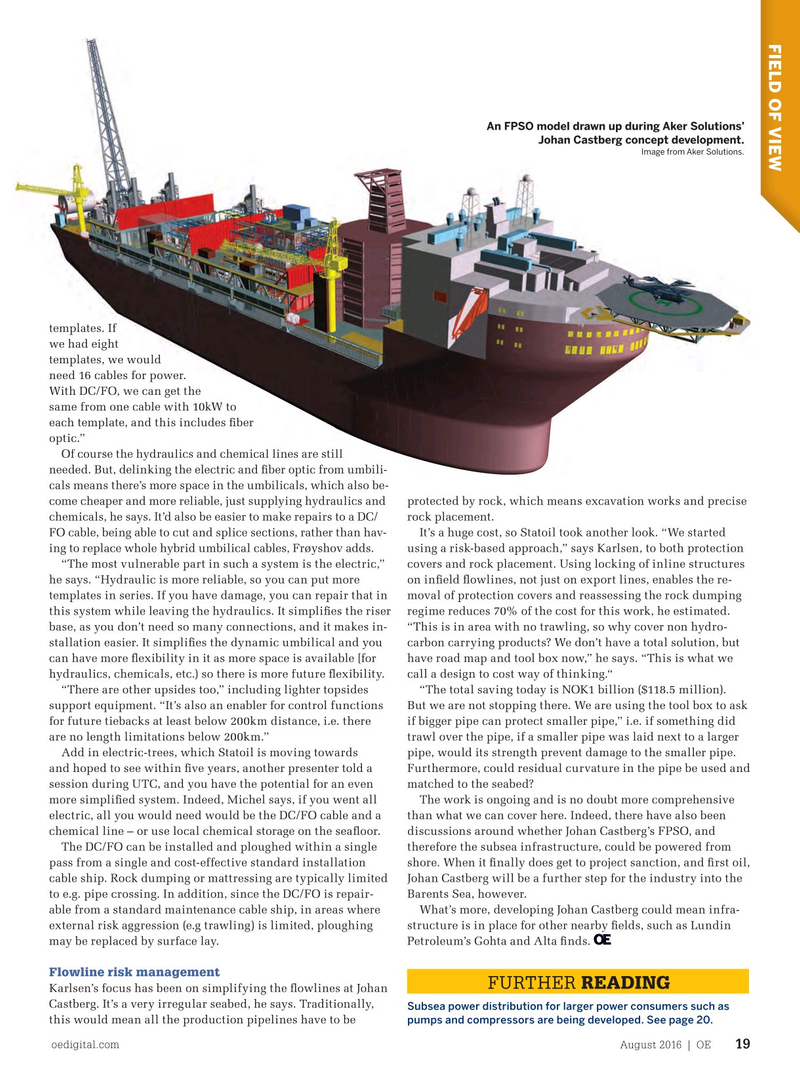

An FPSO model drawn up during Aker Solutions’

Johan Castberg concept development.

Image from Aker Solutions.

templates. If templates. If we had eight we had eight templates, we would templates, we would need 16 cables for power. need 16 cables for power.

With DC/FO, we can get the With DC/FO, we can get the same from one cable with 10kW to same from one cable with 10kW to each template, and this includes ? ber each template, and this includes ? ber optic.”optic.”

Of course the hydraulics and chemical lines are still Of course the hydraulics and chemical lines are still needed. But, delinking the electric and ? ber optic from umbili-needed. But, delinking the electric and ? ber optic from umbili- cals means there’s more space in the umbilicals, which also be- come cheaper and more reliable, just supplying hydraulics and protected by rock, which means excavation works and precise chemicals, he says. It’d also be easier to make repairs to a DC/ rock placement.

FO cable, being able to cut and splice sections, rather than hav- It’s a huge cost, so Statoil took another look. “We started ing to replace whole hybrid umbilical cables, Frøyshov adds. using a risk-based approach,” says Karlsen, to both protection “The most vulnerable part in such a system is the electric,” covers and rock placement. Using locking of inline structures he says. “Hydraulic is more reliable, so you can put more on in? eld ? owlines, not just on export lines, enables the re- templates in series. If you have damage, you can repair that in moval of protection covers and reassessing the rock dumping this system while leaving the hydraulics. It simpli? es the riser regime reduces 70% of the cost for this work, he estimated. base, as you don’t need so many connections, and it makes in- “This is in area with no trawling, so why cover non hydro- stallation easier. It simpli? es the dynamic umbilical and you carbon carrying products? We don’t have a total solution, but can have more ? exibility in it as more space is available [for have road map and tool box now,” he says. “This is what we hydraulics, chemicals, etc.) so there is more future ? exibility. call a design to cost way of thinking.“ “There are other upsides too,” including lighter topsides “The total saving today is NOK1 billion ($118.5 million). support equipment. “It’s also an enabler for control functions But we are not stopping there. We are using the tool box to ask for future tiebacks at least below 200km distance, i.e. there if bigger pipe can protect smaller pipe,” i.e. if something did are no length limitations below 200km.” trawl over the pipe, if a smaller pipe was laid next to a larger

Add in electric-trees, which Statoil is moving towards pipe, would its strength prevent damage to the smaller pipe. and hoped to see within ? ve years, another presenter told a Furthermore, could residual curvature in the pipe be used and session during UTC, and you have the potential for an even matched to the seabed? more simpli? ed system. Indeed, Michel says, if you went all The work is ongoing and is no doubt more comprehensive electric, all you would need would be the DC/FO cable and a than what we can cover here. Indeed, there have also been chemical line – or use local chemical storage on the sea? oor. discussions around whether Johan Castberg’s FPSO, and

The DC/FO can be installed and ploughed within a single therefore the subsea infrastructure, could be powered from pass from a single and cost-effective standard installation shore. When it ? nally does get to project sanction, and ? rst oil, cable ship. Rock dumping or mattressing are typically limited Johan Castberg will be a further step for the industry into the to e.g. pipe crossing. In addition, since the DC/FO is repair- Barents Sea, however. able from a standard maintenance cable ship, in areas where What’s more, developing Johan Castberg could mean infra- external risk aggression (e.g trawling) is limited, ploughing structure is in place for other nearby ? elds, such as Lundin may be replaced by surface lay. Petroleum’s Gohta and Alta ? nds.

Flowline risk management

FURTHER READING

Karlsen’s focus has been on simplifying the ? owlines at Johan

Castberg. It’s a very irregular seabed, he says. Traditionally,

Subsea power distribution for larger power consumers such as this would mean all the production pipelines have to be pumps and compressors are being developed. See page 20.

oedigital.com August 2016 | OE 19 016_OE0816_field of view.indd 19 7/23/16 11:42 AM

16

16

18

18