Page 52: of Offshore Engineer Magazine (Sep/Oct 2016)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2016 Offshore Engineer Magazine

DRILLING

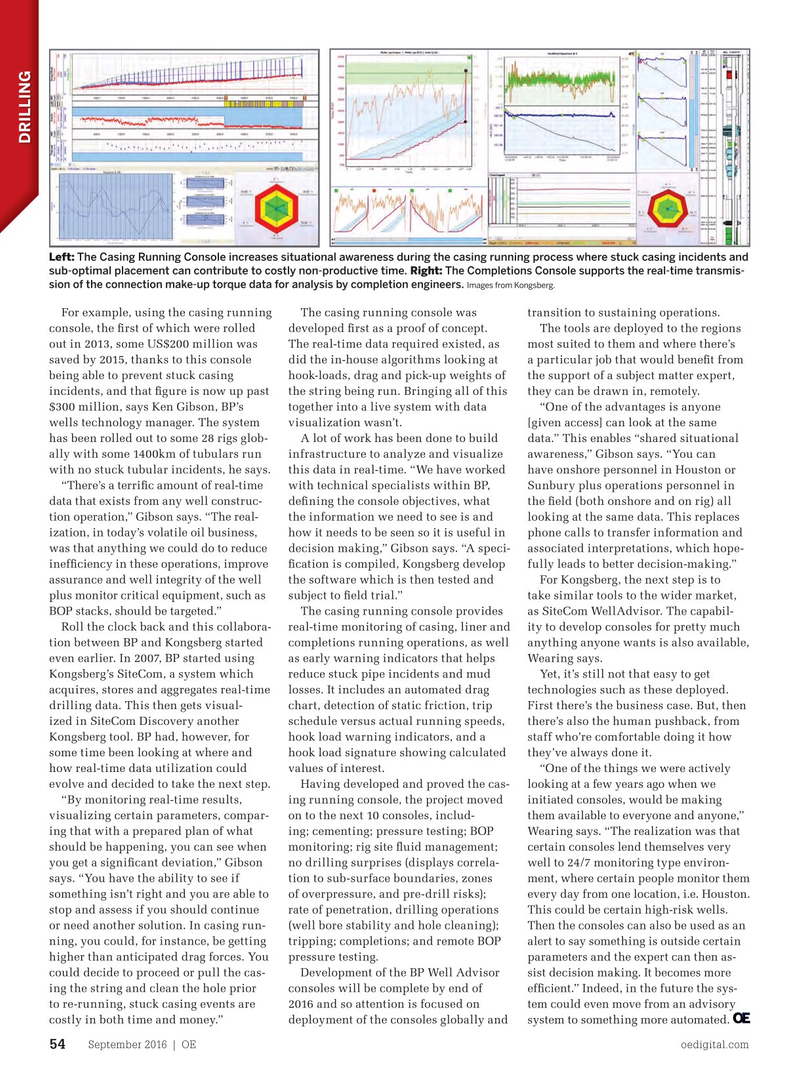

Left: The Casing Running Console increases situational awareness during the casing running process where stuck casing incidents and sub-optimal placement can contribute to costly non-productive time. Right: The Completions Console supports the real-time transmis- sion of the connection make-up torque data for analysis by completion engineers. Images from Kongsberg.

For example, using the casing running The casing running console was transition to sustaining operations. console, the ? rst of which were rolled developed ? rst as a proof of concept. The tools are deployed to the regions out in 2013, some US$200 million was The real-time data required existed, as most suited to them and where there’s saved by 2015, thanks to this console did the in-house algorithms looking at a particular job that would bene? t from being able to prevent stuck casing hook-loads, drag and pick-up weights of the support of a subject matter expert, incidents, and that ? gure is now up past the string being run. Bringing all of this they can be drawn in, remotely. $300 million, says Ken Gibson, BP’s together into a live system with data “One of the advantages is anyone wells technology manager. The system visualization wasn’t. [given access] can look at the same has been rolled out to some 28 rigs glob- A lot of work has been done to build data.” This enables “shared situational ally with some 1400km of tubulars run infrastructure to analyze and visualize awareness,” Gibson says. “You can with no stuck tubular incidents, he says. this data in real-time. “We have worked have onshore personnel in Houston or “There’s a terri? c amount of real-time with technical specialists within BP, Sunbury plus operations personnel in data that exists from any well construc- de? ning the console objectives, what the ? eld (both onshore and on rig) all tion operation,” Gibson says. “The real- the information we need to see is and looking at the same data. This replaces ization, in today’s volatile oil business, how it needs to be seen so it is useful in phone calls to transfer information and was that anything we could do to reduce decision making,” Gibson says. “A speci- associated interpretations, which hope- inef? ciency in these operations, improve ? cation is compiled, Kongsberg develop fully leads to better decision-making.” assurance and well integrity of the well the software which is then tested and For Kongsberg, the next step is to plus monitor critical equipment, such as subject to ? eld trial.” take similar tools to the wider market,

BOP stacks, should be targeted.” The casing running console provides as SiteCom WellAdvisor. The capabil-

Roll the clock back and this collabora- real-time monitoring of casing, liner and ity to develop consoles for pretty much tion between BP and Kongsberg started completions running operations, as well anything anyone wants is also available, even earlier. In 2007, BP started using as early warning indicators that helps Wearing says.

Kongsberg’s SiteCom, a system which reduce stuck pipe incidents and mud Yet, it’s still not that easy to get acquires, stores and aggregates real-time losses. It includes an automated drag technologies such as these deployed. drilling data. This then gets visual- chart, detection of static friction, trip First there’s the business case. But, then ized in SiteCom Discovery another schedule versus actual running speeds, there’s also the human pushback, from

Kongsberg tool. BP had, however, for hook load warning indicators, and a staff who’re comfortable doing it how some time been looking at where and hook load signature showing calculated they’ve always done it. how real-time data utilization could values of interest. “One of the things we were actively evolve and decided to take the next step. Having developed and proved the cas- looking at a few years ago when we “By monitoring real-time results, ing running console, the project moved initiated consoles, would be making visualizing certain parameters, compar- on to the next 10 consoles, includ- them available to everyone and anyone,” ing that with a prepared plan of what ing; cementing; pressure testing; BOP Wearing says. “The realization was that should be happening, you can see when monitoring; rig site ? uid management; certain consoles lend themselves very you get a signi? cant deviation,” Gibson no drilling surprises (displays correla- well to 24/7 monitoring type environ- says. “You have the ability to see if tion to sub-surface boundaries, zones ment, where certain people monitor them something isn’t right and you are able to of overpressure, and pre-drill risks); every day from one location, i.e. Houston. stop and assess if you should continue rate of penetration, drilling operations This could be certain high-risk wells. or need another solution. In casing run- (well bore stability and hole cleaning); Then the consoles can also be used as an ning, you could, for instance, be getting tripping; completions; and remote BOP alert to say something is outside certain higher than anticipated drag forces. You pressure testing. parameters and the expert can then as- could decide to proceed or pull the cas- Development of the BP Well Advisor sist decision making. It becomes more ing the string and clean the hole prior consoles will be complete by end of ef? cient.” Indeed, in the future the sys- to re-running, stuck casing events are 2016 and so attention is focused on tem could even move from an advisory costly in both time and money.” deployment of the consoles globally and system to something more automated.

September 2016 | OE oedigital.com 54 052_OE0916_D&C_WellAdvisor.indd 54 8/24/16 5:01 PM

51

51

53

53