Page 44: of Offshore Engineer Magazine (Jan/Feb 2019)

FPSO/FNLG Outlook and Technologies

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2019 Offshore Engineer Magazine

FEATURE Plugging and Abandonment an upper barrier, again in a well on the Valhall ? eld, creating modular rig’s workscope by doing wireline and coiled tubing what’s been called the world’s largest Bismuth plug. work upfront, including perforate, wash and cementing tech-

The Wel-lok M2M plug was deployed on the A-30 well, niques, which meant less steel had to be pulled out of the well. which already had a cement-based lower abandonment bar- Explosives are used to make holes in the tubing and casing, rier, using an E-line (a type of wireline conveyance into the then washes out these sections so that cement can be pumped well) run by Altus Intervention. Over a couple of hours, some in through all the gaps to make a plug or barrier in that section. 3,500kg of bismuth alloy was placed at 380m downhole and In total, 3,174m of tubing (over 15 wells) was perforated melted to create a 2m-long plug inside 18.625-in casing, during 16 runs, with 67,626 holes made with perforation guns through a section milled window cut in the 13.375-in casing. (using up some 1,887kg of explosives), said Helgesen. The

The heating element was removed at 37 minutes, before the electrically powered Optimus P&A unit, which has 350-met-

Bismuth could set, to remove any possible leak paths it could ric-ton pulling capability (and can be upgraded to 500-metric- create, Straume said. ton), then did the remaining work that couldn’t be done by

A bene? t of the Bismuth is that it effectively locks itself in wireline or coiled tubing. The conductors will be removed by place, because it expands the casing it’s in, he said. This also heavy lift vessel.

exerts pressure on the surrounding rock, creating a tight seal.

For Straume, using both cement and one or both of these new Making an Intervention technologies could be a good solution. “If cement is used for When there’s not a platform to work from, as on Cono- multiple barriers in a well, it has the same failure mechanism,” coPhillips’ MacCulloch ? eld, a modular rig cannot be used. he pointed out. “If cement and another medium is used, there ConocoPhillips used a light well intervention vessel (LWIV) are different failure mechanisms, so you’re less likely to fail to remove well suspension work the subsequent semisubmers- across the multiple barriers.” ible rig campaign.

The goal for both of these tools is helping to reduce how MacCulloch, which produced 120MMbbl from 1997 to much steel (tubing and casing) needs to be pulled out of the 2015, when it was shut-in, was developed via 11 wells, from wells, as well as to create long-term impermeable barriers. two drill centers tied back to the North Sea Producer ? oating production, storage and of? oad-

More with Modular ing vessel (FPSO), in the U.K.

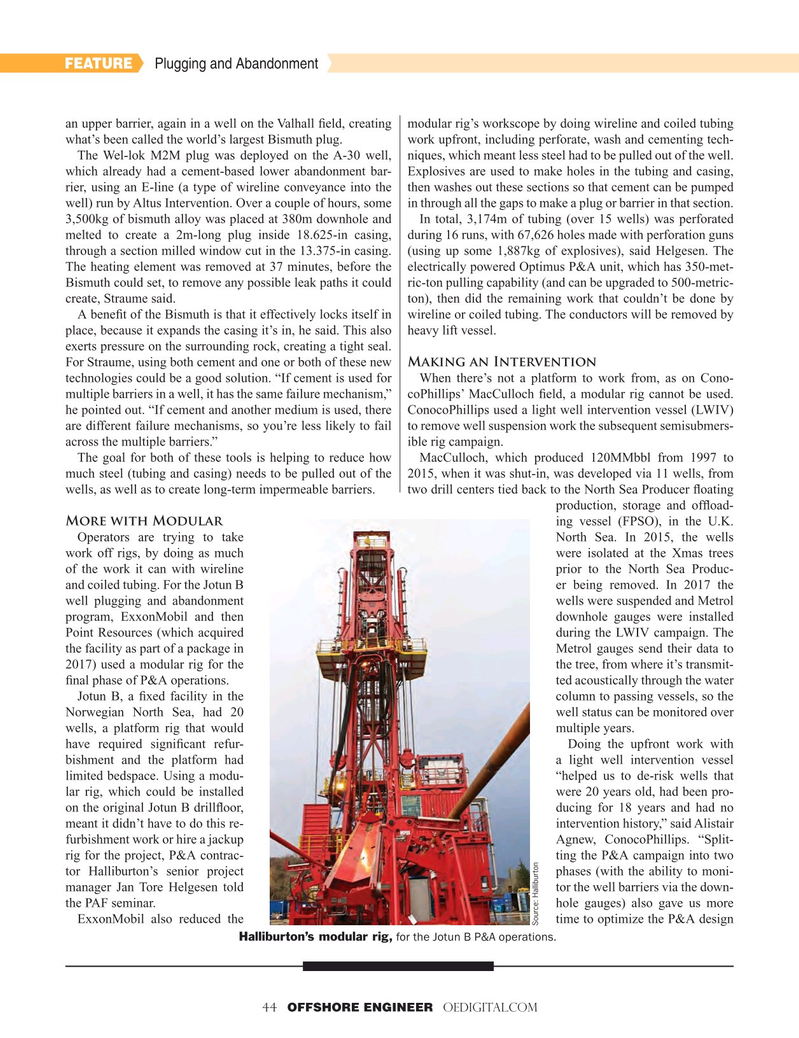

Operators are trying to take North Sea. In 2015, the wells work off rigs, by doing as much were isolated at the Xmas trees of the work it can with wireline prior to the North Sea Produc- and coiled tubing. For the Jotun B er being removed. In 2017 the well plugging and abandonment wells were suspended and Metrol program, ExxonMobil and then downhole gauges were installed

Point Resources (which acquired during the LWIV campaign. The the facility as part of a package in Metrol gauges send their data to 2017) used a modular rig for the the tree, from where it’s transmit- ? nal phase of P&A operations. ted acoustically through the water

Jotun B, a ? xed facility in the column to passing vessels, so the

Norwegian North Sea, had 20 well status can be monitored over wells, a platform rig that would multiple years.

have required signi? cant refur- Doing the upfront work with bishment and the platform had a light well intervention vessel limited bedspace. Using a modu- “helped us to de-risk wells that lar rig, which could be installed were 20 years old, had been pro- on the original Jotun B drill? oor, ducing for 18 years and had no meant it didn’t have to do this re- intervention history,” said Alistair furbishment work or hire a jackup Agnew, ConocoPhillips. “Split- rig for the project, P&A contrac- ting the P&A campaign into two tor Halliburton’s senior project phases (with the ability to moni- manager Jan Tore Helgesen told tor the well barriers via the down- the PAF seminar. hole gauges) also gave us more

ExxonMobil also reduced the time to optimize the P&A design

Source: Halliburton

Halliburton’s modular rig, for the Jotun B P&A operations. 44 OFFSHORE ENGINEER OEDIGITAL.COM 32-49 OE 2019.indd 44 32-49 OE 2019.indd 44 1/21/2019 3:28:36 PM1/21/2019 3:28:36 PM

43

43

45

45