Page 43: of Offshore Engineer Magazine (May/Jun 2019)

Offshore Renewables Review

Read this page in Pdf, Flash or Html5 edition of May/Jun 2019 Offshore Engineer Magazine

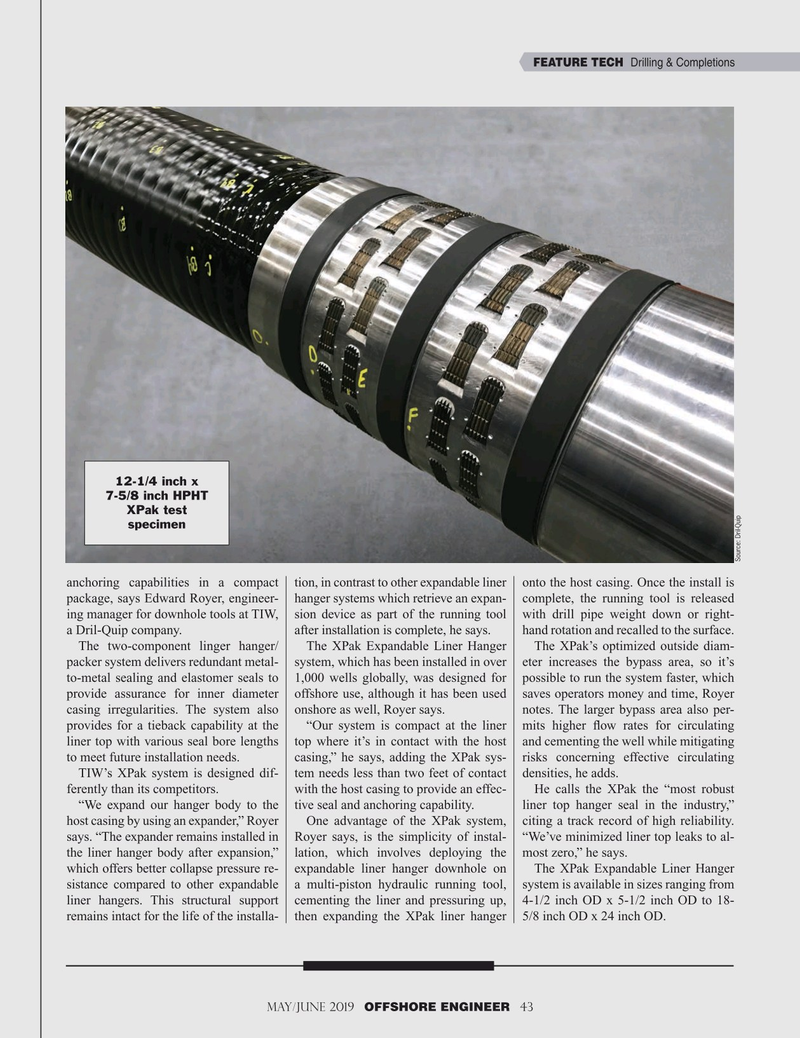

FEATURE TECH Drilling & Completions 12-1/4 inch x 7-5/8 inch HPHT

XPak test specimen

Source: Dril-Quip anchoring capabilities in a compact tion, in contrast to other expandable liner onto the host casing. Once the install is package, says Edward Royer, engineer- hanger systems which retrieve an expan- complete, the running tool is released ing manager for downhole tools at TIW, sion device as part of the running tool with drill pipe weight down or right- a Dril-Quip company. after installation is complete, he says. hand rotation and recalled to the surface.

The two-component linger hanger/ The XPak Expandable Liner Hanger The XPak’s optimized outside diam- packer system delivers redundant metal- system, which has been installed in over eter increases the bypass area, so it’s to-metal sealing and elastomer seals to 1,000 wells globally, was designed for possible to run the system faster, which provide assurance for inner diameter offshore use, although it has been used saves operators money and time, Royer casing irregularities. The system also onshore as well, Royer says. notes. The larger bypass area also per- provides for a tieback capability at the “Our system is compact at the liner mits higher ? ow rates for circulating liner top with various seal bore lengths top where it’s in contact with the host and cementing the well while mitigating to meet future installation needs. casing,” he says, adding the XPak sys- risks concerning effective circulating

TIW’s XPak system is designed dif- tem needs less than two feet of contact densities, he adds.

ferently than its competitors. with the host casing to provide an effec- He calls the XPak the “most robust “We expand our hanger body to the tive seal and anchoring capability. liner top hanger seal in the industry,” host casing by using an expander,” Royer One advantage of the XPak system, citing a track record of high reliability. says. “The expander remains installed in Royer says, is the simplicity of instal- “We’ve minimized liner top leaks to al- the liner hanger body after expansion,” lation, which involves deploying the most zero,” he says.

which offers better collapse pressure re- expandable liner hanger downhole on The XPak Expandable Liner Hanger sistance compared to other expandable a multi-piston hydraulic running tool, system is available in sizes ranging from liner hangers. This structural support cementing the liner and pressuring up, 4-1/2 inch OD x 5-1/2 inch OD to 18- remains intact for the life of the installa- then expanding the XPak liner hanger 5/8 inch OD x 24 inch OD.

MaY/JUNE 2019 OFFSHORE ENGINEER 43

42

42

44

44