Page 59: of Offshore Engineer Magazine (May/Jun 2019)

Offshore Renewables Review

Read this page in Pdf, Flash or Html5 edition of May/Jun 2019 Offshore Engineer Magazine

TECH FILE Subsea Water Treatment analyses, all performed by an independent third-party lab that potable water. The SDI is used as a measurement for foul- specializes in services for the upstream oil and gas industry. ing or plugging potential. During the eight samples taken, the

To verify the water disinfection capabilities of the module, Seabox provided SDI levels ranging between three and four, e.g. the abilities of the module to remove, deactivate or kill mi- which is acceptable to potential downstream nano? ltration ap- croorganisms in the seawater, planktonic and sessile general plications, should this be required. By comparison, ? ve out heterotrophic bacteria (GHB) and sulphate reducing bacteria of eight raw seawater samples had an SDI above its measure- (SRB), adenosine triphosphate (ATP) and quantitative poly- ment range at SDI of 6. merase chain reaction (qPCR) was measured throughout the veri? cation program. The general results through these samples

Future potential showed that both the planktonic and sessile levels in the treated

This veri? cation of the Seabox capabilities to disinfect and water were below detectable levels. The results are further sup- remove particles from the seawater, and the installation ? ex- ported by the ATP and qPCR samples. Comparing ATP levels ibility, provides a new ability to add water? ooding to marginal from the raw seawater and treated seawater, on average a total ? eld developments. When located on the seabed next to a water 98.6% of all microorganisms were inactivated by the disinfec- injector, the module can provide an improved ? ooding regime tion process within the module. The qPCR showed a total de- to ensure necessary pressure support and sweep ef? ciency. This crease in bacteria level with 99.8% and 100% for the SRB count. can increase the oil recovery rate potential as the reservoir is ex-

The results con? rmed the module’s ability to provide disinfected ploited to its full capacity. The system is believed to be a strong water through the electrolysis process and use of residence time. contender for improving water? ooding for both green- and

To verify the solid removal capabilities, NOV used Coulter brown? elds. Not only has NOV demonstrated its performance

Counter, turbidity and silt density index (SDI) as sampling through an extensive veri? cation program, the Seabox module methods. The Coulter Counter provides a measurement of the has also been in continuous operation at the Eko? sk ? eld in the particle count and size distribution. The comparison of the North Sea since autumn 2018 with 100% uptime to date.

raw seawater samples and the Seabox-treated water showed a

This technology is a competitive solution to provide in- signi? cant effect on the sedimentation ability for the module. creased water treatment capacity to mature brown? elds or to

On average, the particle count for the raw seawater was about provide high quality water to marginal developments. It can 10 times higher compared to the Seabox treated water for par- also be used as a hybrid solution where the subsea water treat- ticles larger than 2µm. Through turbidity measurement it was ment system is used as a pretreatment step upstream existing possible to measure the concentration of suspended particles topside water treatment facilities to face well-known challeng- in the water. The turbidity of the Seabox measured around 1 es like biofouling. This can reduce operational expenditures

FTU, which is within the range of turbidity measurements in and increase availability of the overall water treatment system.

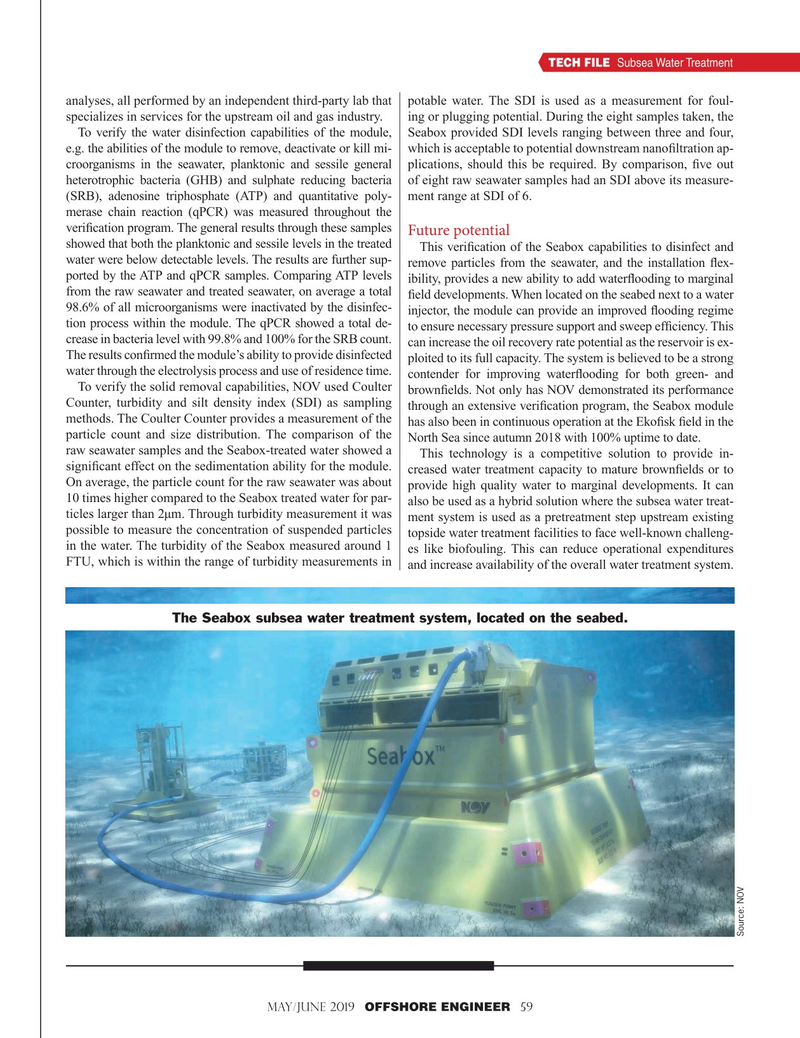

The Seabox subsea water treatment system, located on the seabed.

Source: NOV

MAY/JUNE 2019 OFFSHORE ENGINEER 59 50-64 OE MayJune 2019.indd 59 6/10/2019 10:29:41 AM

58

58

60

60