Page 24: of Offshore Engineer Magazine (Sep/Oct 2019)

Big Data and Digitalization

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2019 Offshore Engineer Magazine

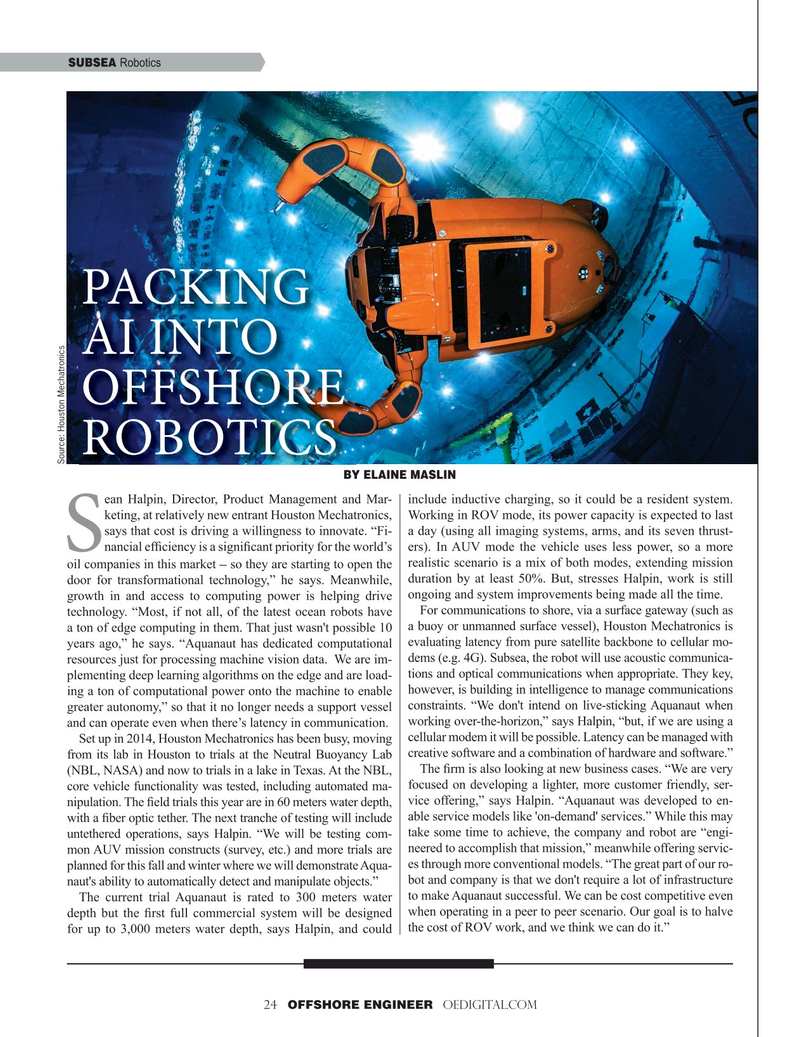

SUBSEA Robotics

PACKING

AI INTO

OFFSHORE

ROBOTICS

Source: Houston Mechatronics

BY ELAINE MASLIN ean Halpin, Director, Product Management and Mar- include inductive charging, so it could be a resident system. keting, at relatively new entrant Houston Mechatronics, Working in ROV mode, its power capacity is expected to last says that cost is driving a willingness to innovate. “Fi- a day (using all imaging systems, arms, and its seven thrust-

Snancial ef? ciency is a signi? cant priority for the world’s ers). In AUV mode the vehicle uses less power, so a more oil companies in this market so they are starting to open the realistic scenario is a mix of both modes, extending mission – door for transformational technology,” he says. Meanwhile, duration by at least 50%. But, stresses Halpin, work is still growth in and access to computing power is helping drive ongoing and system improvements being made all the time.

For communications to shore, via a surface gateway (such as technology. “Most, if not all, of the latest ocean robots have a ton of edge computing in them. That just wasn't possible 10 a buoy or unmanned surface vessel), Houston Mechatronics is years ago,” he says. “Aquanaut has dedicated computational evaluating latency from pure satellite backbone to cellular mo- dems (e.g. 4G). Subsea, the robot will use acoustic communica- resources just for processing machine vision data. We are im- tions and optical communications when appropriate. They key, plementing deep learning algorithms on the edge and are load- ing a ton of computational power onto the machine to enable however, is building in intelligence to manage communications greater autonomy,” so that it no longer needs a support vessel constraints. “We don't intend on live-sticking Aquanaut when working over-the-horizon,” says Halpin, “but, if we are using a and can operate even when there’s latency in communication.

Set up in 2014, Houston Mechatronics has been busy, moving cellular modem it will be possible. Latency can be managed with from its lab in Houston to trials at the Neutral Buoyancy Lab creative software and a combination of hardware and software.”

The ? rm is also looking at new business cases. “We are very (NBL, NASA) and now to trials in a lake in Texas. At the NBL, focused on developing a lighter, more customer friendly, ser- core vehicle functionality was tested, including automated ma- nipulation. The ? eld trials this year are in 60 meters water depth, vice offering,” says Halpin. “Aquanaut was developed to en- with a ? ber optic tether. The next tranche of testing will include able service models like 'on-demand' services.” While this may take some time to achieve, the company and robot are “engi- untethered operations, says Halpin. “We will be testing com- mon AUV mission constructs (survey, etc.) and more trials are neered to accomplish that mission,” meanwhile offering servic- es through more conventional models. “The great part of our ro- planned for this fall and winter where we will demonstrate Aqua- bot and company is that we don't require a lot of infrastructure naut's ability to automatically detect and manipulate objects.”

The current trial Aquanaut is rated to 300 meters water to make Aquanaut successful. We can be cost competitive even depth but the ? rst full commercial system will be designed when operating in a peer to peer scenario. Our goal is to halve for up to 3,000 meters water depth, says Halpin, and could the cost of ROV work, and we think we can do it.” 24 OFFSHORE ENGINEER OEDIGITAL.COM

23

23

25

25