Page 29: of Offshore Engineer Magazine (Jan/Feb 2020)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2020 Offshore Engineer Magazine

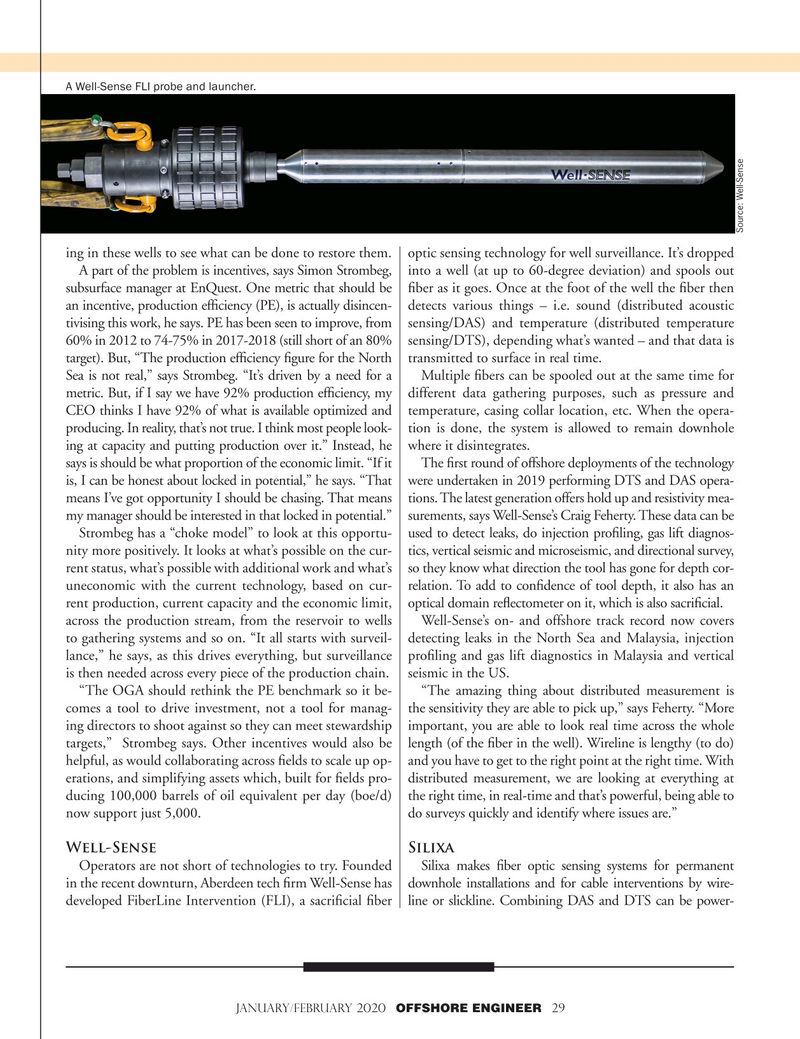

A Well-Sense FLI probe and launcher.

Source: Well-Sense ing in these wells to see what can be done to restore them. optic sensing technology for well surveillance. It’s dropped

A part of the problem is incentives, says Simon Strombeg, into a well (at up to 60-degree deviation) and spools out subsurface manager at EnQuest. One metric that should be ? ber as it goes. Once at the foot of the well the ? ber then an incentive, production ef? ciency (PE), is actually disincen- detects various things – i.e. sound (distributed acoustic tivising this work, he says. PE has been seen to improve, from sensing/DAS) and temperature (distributed temperature 60% in 2012 to 74-75% in 2017-2018 (still short of an 80% sensing/DTS), depending what’s wanted – and that data is target). But, “The production ef? ciency ? gure for the North transmitted to surface in real time.

Sea is not real,” says Strombeg. “It’s driven by a need for a Multiple ? bers can be spooled out at the same time for metric. But, if I say we have 92% production ef? ciency, my different data gathering purposes, such as pressure and

CEO thinks I have 92% of what is available optimized and temperature, casing collar location, etc. When the opera- producing. In reality, that’s not true. I think most people look- tion is done, the system is allowed to remain downhole ing at capacity and putting production over it.” Instead, he where it disintegrates. says is should be what proportion of the economic limit. “If it The ? rst round of offshore deployments of the technology is, I can be honest about locked in potential,” he says. “That were undertaken in 2019 performing DTS and DAS opera- means I’ve got opportunity I should be chasing. That means tions. The latest generation offers hold up and resistivity mea- my manager should be interested in that locked in potential.” surements, says Well-Sense’s Craig Feherty. These data can be

Strombeg has a “choke model” to look at this opportu- used to detect leaks, do injection pro? ling, gas lift diagnos- nity more positively. It looks at what’s possible on the cur- tics, vertical seismic and microseismic, and directional survey, rent status, what’s possible with additional work and what’s so they know what direction the tool has gone for depth cor- uneconomic with the current technology, based on cur- relation. To add to con? dence of tool depth, it also has an rent production, current capacity and the economic limit, optical domain re? ectometer on it, which is also sacri? cial.

across the production stream, from the reservoir to wells Well-Sense’s on- and offshore track record now covers to gathering systems and so on. “It all starts with surveil- detecting leaks in the North Sea and Malaysia, injection lance,” he says, as this drives everything, but surveillance pro? ling and gas lift diagnostics in Malaysia and vertical is then needed across every piece of the production chain. seismic in the US.

“The OGA should rethink the PE benchmark so it be- “The amazing thing about distributed measurement is comes a tool to drive investment, not a tool for manag- the sensitivity they are able to pick up,” says Feherty. “More ing directors to shoot against so they can meet stewardship important, you are able to look real time across the whole targets,” Strombeg says. Other incentives would also be length (of the ? ber in the well). Wireline is lengthy (to do) helpful, as would collaborating across ? elds to scale up op- and you have to get to the right point at the right time. With erations, and simplifying assets which, built for ? elds pro- distributed measurement, we are looking at everything at ducing 100,000 barrels of oil equivalent per day (boe/d) the right time, in real-time and that’s powerful, being able to now support just 5,000. do surveys quickly and identify where issues are.”

Well-Sense Silixa

Operators are not short of technologies to try. Founded Silixa makes ? ber optic sensing systems for permanent in the recent downturn, Aberdeen tech ? rm Well-Sense has downhole installations and for cable interventions by wire- developed FiberLine Intervention (FLI), a sacri? cial ? ber line or slickline. Combining DAS and DTS can be power-

JANUARY/fEBRUARY 2020 OFFSHORE ENGINEER 29

28

28

30

30