Page 56: of Offshore Engineer Magazine (Jan/Feb 2020)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2020 Offshore Engineer Magazine

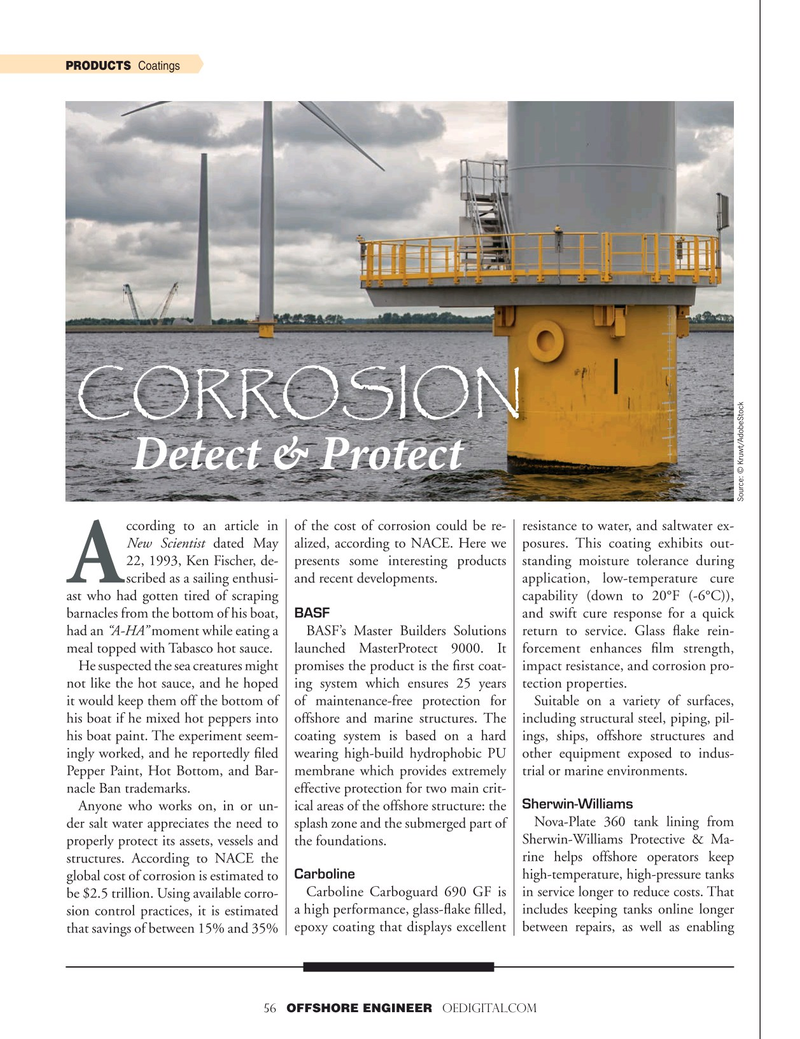

PRODUCTS Coatings

CORROSION

Detect & Protect

Source: © Kruwt/AdobeStock ccording to an article in of the cost of corrosion could be re- resistance to water, and saltwater ex-

New Scientist dated May alized, according to NACE. Here we posures. This coating exhibits out- 22, 1993, Ken Fischer, de- presents some interesting products standing moisture tolerance during scribed as a sailing enthusi- and recent developments. application, low-temperature cure

A ast who had gotten tired of scraping capability (down to 20°F (-6°C)), barnacles from the bottom of his boat, and swift cure response for a quick

BASF had an “A-HA” moment while eating a BASF’s Master Builders Solutions return to service. Glass ? ake rein- meal topped with Tabasco hot sauce. launched MasterProtect 9000. It forcement enhances ? lm strength,

He suspected the sea creatures might promises the product is the ? rst coat- impact resistance, and corrosion pro- not like the hot sauce, and he hoped ing system which ensures 25 years tection properties.

it would keep them off the bottom of of maintenance-free protection for Suitable on a variety of surfaces, his boat if he mixed hot peppers into offshore and marine structures. The including structural steel, piping, pil- his boat paint. The experiment seem- coating system is based on a hard ings, ships, offshore structures and ingly worked, and he reportedly ? led wearing high-build hydrophobic PU other equipment exposed to indus-

Pepper Paint, Hot Bottom, and Bar- membrane which provides extremely trial or marine environments.

nacle Ban trademarks. effective protection for two main crit-

Sherwin-Williams

Anyone who works on, in or un- ical areas of the offshore structure: the

Nova-Plate 360 tank lining from der salt water appreciates the need to splash zone and the submerged part of

Sherwin-Williams Protective & Ma- properly protect its assets, vessels and the foundations. rine helps offshore operators keep structures. According to NACE the

Carboline high-temperature, high-pressure tanks global cost of corrosion is estimated to

Carboline Carboguard 690 GF is in service longer to reduce costs. That be $2.5 trillion. Using available corro- sion control practices, it is estimated a high performance, glass-? ake ? lled, includes keeping tanks online longer that savings of between 15% and 35% epoxy coating that displays excellent between repairs, as well as enabling 56 OFFSHORE ENGINEER OEDIGITAL.COM

55

55

57

57