Page 27: of Offshore Engineer Magazine (Mar/Apr 2020)

Offshore Wind Outlook

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2020 Offshore Engineer Magazine

research community SINTEF and commercialization partner, LedaFlow monitoring for its slug catcher array. However, the

Kongsberg Digital. Branch?ower has worked in ?ow assur- use and availability of LedaFlow to manage hydrates in deep- ance (hydrates, sand, scale) for years and is now strategic sales water is news. The new app will, it is understood, combine manager for Kongsberg Digital’s energy division. LedaFlow hydrate monitoring with riser fatigue modelling

Offshore Engineer is ?rst to publish news on this major software now being tested. breakthrough of cost (management and safety) by the con- Perplexing to some — especially for its use of blockchain sortium ahead of it launching hydrate monitoring software coding language — company multimedia nevertheless re- for the Cloud and a technology suite of related apps later this veals how much of the LedaFlow offering is revolutionary year. “LedaFlow is the only technology that can calculate slugs for deepwater costs. The savings ought to allow the consid- and it will be the ?rst to deploy this tech in the cloud. It is a eration of smaller deepwater hydrocarbon accumulations, ?rst,” Branch?ower says. where the drilling of a well alone in the CAPEX stage can

The new slug monitoring tech is already in the North Sea cost well over USD 100 million. Relaying OPEX savings as part of a pilot to study hydrate interaction with produc- early will go a long way toward helping operators decide tion risers. On land, Shell has commissioned a digital twin ?nal investment decisions.

of the Nyhamna gas processing plant in Norway that will use

Conserve inhibitor

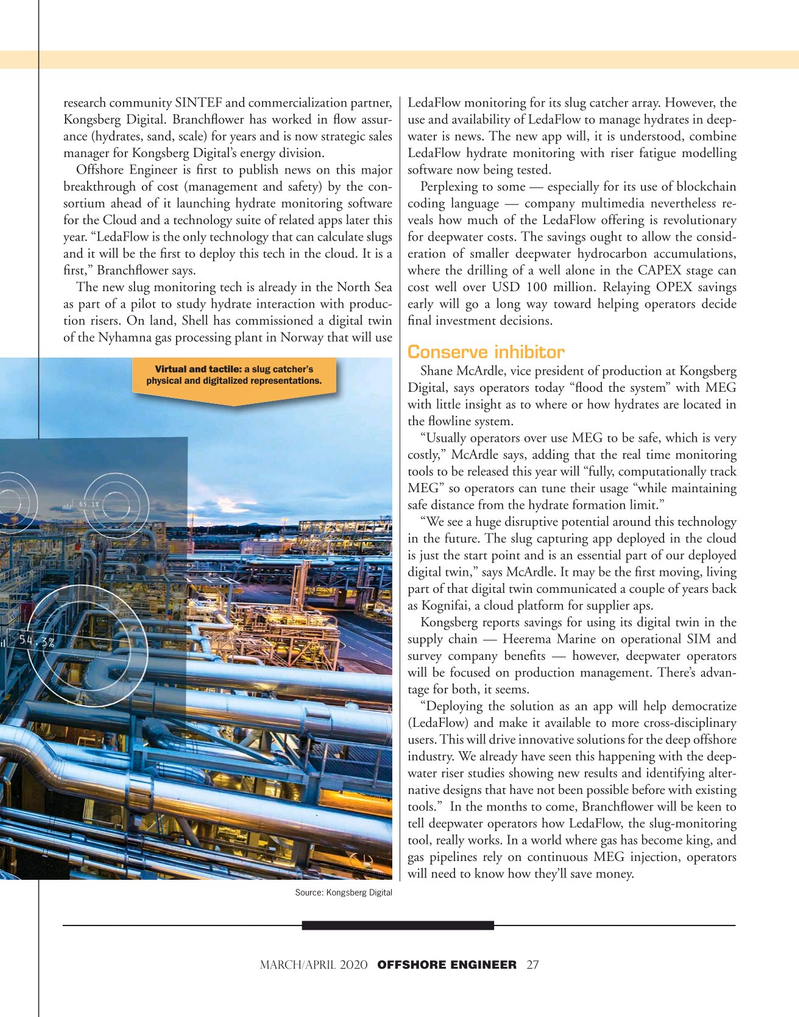

Virtual and tactile: a slug catcher’s

Shane McArdle, vice president of production at Kongsberg physical and digitalized representations.

Digital, says operators today “?ood the system” with MEG with little insight as to where or how hydrates are located in the ?owline system.

“Usually operators over use MEG to be safe, which is very costly,” McArdle says, adding that the real time monitoring tools to be released this year will “fully, computationally track

MEG” so operators can tune their usage “while maintaining safe distance from the hydrate formation limit.” “We see a huge disruptive potential around this technology in the future. The slug capturing app deployed in the cloud is just the start point and is an essential part of our deployed digital twin,” says McArdle. It may be the ?rst moving, living part of that digital twin communicated a couple of years back as Kognifai, a cloud platform for supplier aps.

Kongsberg reports savings for using its digital twin in the supply chain — Heerema Marine on operational SIM and survey company bene?ts — however, deepwater operators will be focused on production management. There’s advan- tage for both, it seems.

“Deploying the solution as an app will help democratize (LedaFlow) and make it available to more cross-disciplinary users. This will drive innovative solutions for the deep offshore industry. We already have seen this happening with the deep- water riser studies showing new results and identifying alter- native designs that have not been possible before with existing tools.” In the months to come, Branch?ower will be keen to tell deepwater operators how LedaFlow, the slug-monitoring tool, really works. In a world where gas has become king, and gas pipelines rely on continuous MEG injection, operators will need to know how they’ll save money.

Source: Kongsberg Digital march/april 2020 OFFSHORE ENGINEER 27

26

26

28

28