Page 36: of Offshore Engineer Magazine (May/Jun 2020)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2020 Offshore Engineer Magazine

FEATURE OFFSHORE WIND POWER

FLOATING TURBINES WILL ENABLE WIND FARM CONSTRUCTION IN

DEEPER WATERS THAT HOLD SOME 80% OF THE WORLD’S WIND

CAPACITY POTENTIAL. A PIPELINE OF MORE THAN 50 GW OF FLOATING

CAPACITY REQUIRING $93 BILLION TO $148 BILLION OF CAPEX

INVESTMENT HAS BEEN IDENTIFIED BY WER. trialization of the hull construction process is helping certain the development of a much large pipeline after the middle of concepts reduce project LCOE. For example, as Equinor ma- this decade, with potential zones discussed in the U.S., Japan, tures the technology, it aims to bring the LCOE of Hywind Norway, U.K. and France.

projects to €40 -60/MWh by 2030.

Big Potential Opportunities

A pipeline of more than 50 GW of foating capacity requir- ing $93 billion to $148 billion of capex investment has been Forecasted near- and long-term increased activity bodes very identifed by WER. As is the case in the bottom-fxed seg- well for the global supply chain. WER expects offshore wind ment, the U.K. presently has the largest foating pipeline at projects will require between $1 trillion and $1.5 trillion of more than 25 GW, followed by Norway (more than 5 GW) capex over the next two decades. Much is still on the table for and Japan, the U.S., South Korea, Ireland, France and Tai- the gamut of suppliers and marine services frms, as 80% of wan, each with multi-GW pipelines. WER’s report highlights offshore wind projects detailed in the report and database are

WIND TECH 80%

THE MAJORITY OF

FLOATING FUTURE

OFFSHORE WIND’S

POTENTIAL LIE IN DEEP

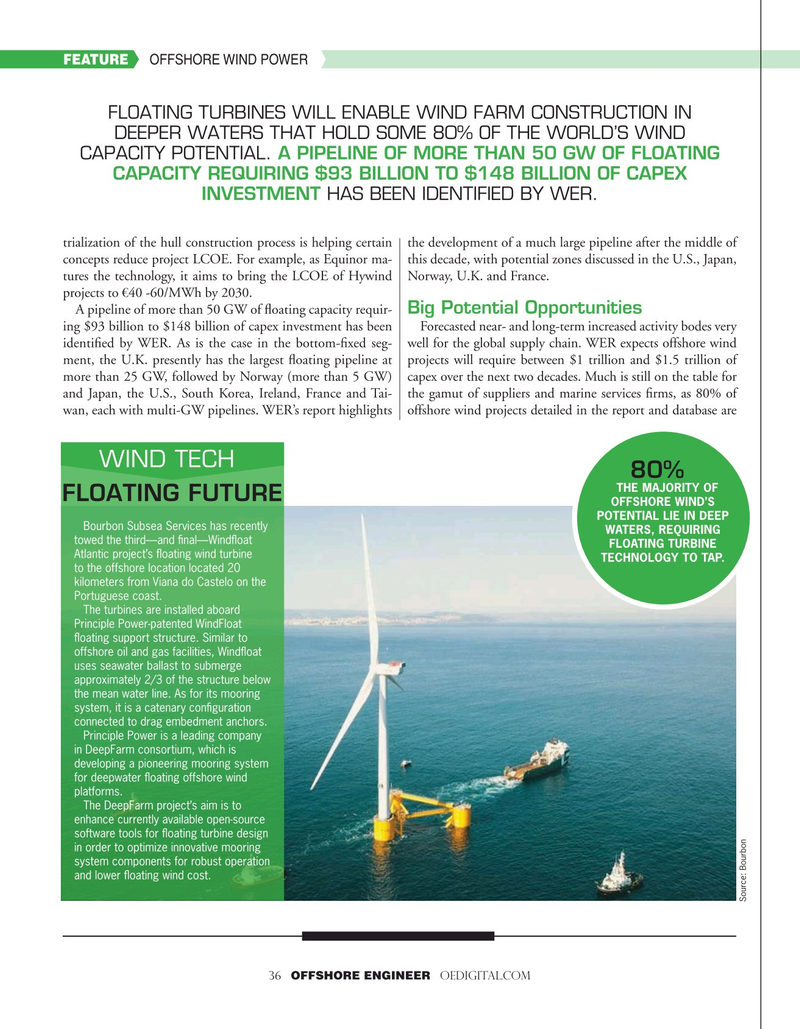

Bourbon Subsea Services has recently

WATERS, REQUIRING towed the third—and fnal—Windfoat

FLOATING TURBINE

Atlantic project’s foating wind turbine

TECHNOLOGY TO TAP.

to the offshore location located 20 kilometers from Viana do Castelo on the

Portuguese coast.

The turbines are installed aboard

Principle Power-patented WindFloat foating support structure. Similar to offshore oil and gas facilities, Windfoat uses seawater ballast to submerge approximately 2/3 of the structure below the mean water line. As for its mooring system, it is a catenary confguration connected to drag embedment anchors.

Principle Power is a leading company in DeepFarm consortium, which is developing a pioneering mooring system for deepwater foating offshore wind platforms.

The DeepFarm project’s aim is to enhance currently available open-source software tools for foating turbine design in order to optimize innovative mooring system components for robust operation and lower foating wind cost.

Source: Bourbon 36 OFFSHORE ENGINEER OEDIGITAL.COM

35

35

37

37