Page 22: of Offshore Engineer Magazine (Jul/Aug 2020)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2020 Offshore Engineer Magazine

ROBOTICS in response to the Elgin/Franklin gas leak in 2012 had it had things and people from robotics,” says Alex Loudon, the UK’s a suitable robotic system on board, for example. Offshore Renewable Energy (ORE) Catapult. “Everything is

What’s now underway is a drive to get those systems al- linear, there’s no wind, waves or currents to get in the way. It’s ready being used able to do more themselves and for newer so much easier to implement automation. When you think platforms to be more offshore ready, for tasks from internal about offshore wind, it’s a different beast entirely, because of inspection to grit-blasting and even X-rays and repairs on the operating environment.” wind turbine blades. It’s not an easy task and the challenges are not all robotic.

A raft of new systems

Still, there are plenty of ongoing projects. The OGTC has

Reducing risk and emissions been working with drone ?rms Air Control Entech and Fly “Robotics take people out of harsh environments and could Logix on aerial systems. Air Control Entech developed three be more ef?cient,” and they could also help meet net-zero drones – one for ?ying in higher winds, one with laser scan- emissions goals, reducing the need for helicopter ?ights, etc., ning capability, and one with ultrasonic non-destructive test- says Andy Bell, Project Manager, Asset Integrity Solution ing capability, says Bell. In its ?rst project with the OGTC, Fly

Centre, at the publicly-funded Oil & Gas Technology Centre Logix’s worked on a drone capable of “beyond visual line of (OGTC). But offshore facilities weren’t designed for robotics sight” (BVLOS). Its latest project with the OGTC is to devel- and robotics can’t function as well as humans. “Simple things, op a drone for methane monitoring, using long-distance ?xed- like climbing stairs, we take for granted, robots can’t,” he says. wing drones. “There’s not a one size ?ts all,” says Bell, “there “In a production plant, everything is pretty static and con- will be different solutions for different applications. I think the trolled. It’s easy to separate moving things from non-moving technology is there, we just need to start trialling it in the ?eld

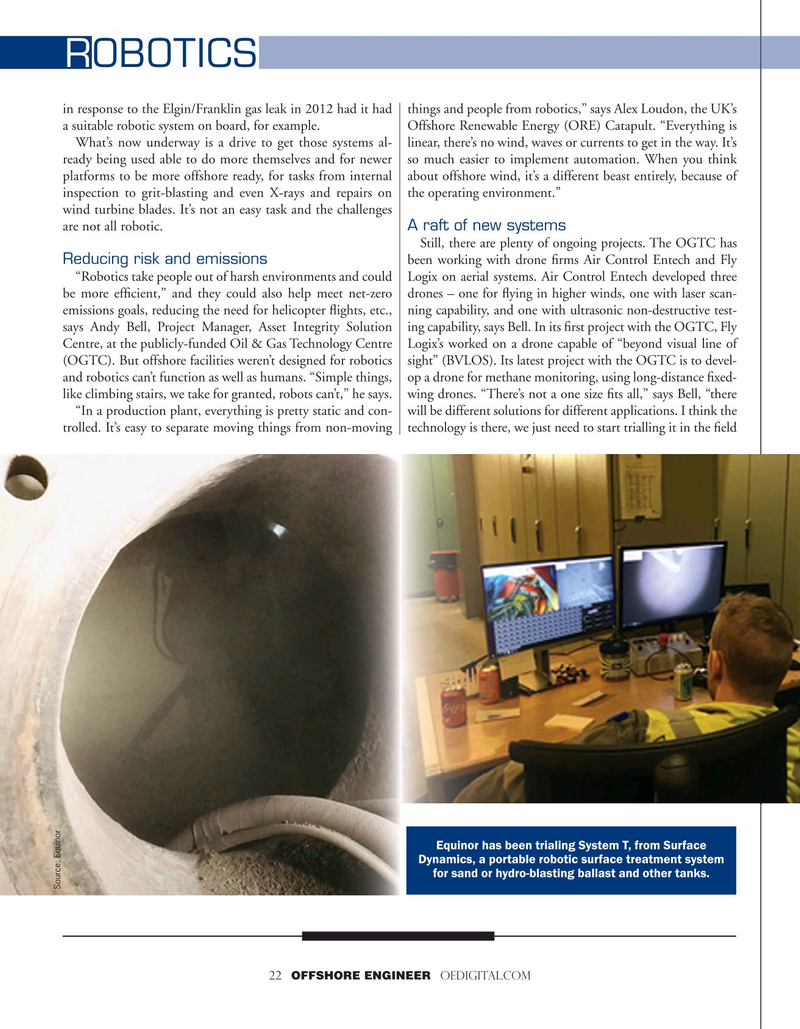

Equinor has been trialing System T, from Surface

Dynamics, a portable robotic surface treatment system for sand or hydro-blasting ballast and other tanks.

Source: Equinor 22 OFFSHORE ENGINEER OEDIGITAL.COM

21

21

23

23