Page 25: of Offshore Engineer Magazine (Jul/Aug 2020)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2020 Offshore Engineer Magazine

above and down to 60m below the waterline using ultrasonic testing. The procedure is currently done by divers or ROVs and is reliant on weather windows.

Another, RadBlad, by Innovotek working with London

South Bank Innovation Centre, Forth Engineering, Renew- able Advice and The Welding Institute, is looking to deploy a robotic system able to scale towers and perform radiography on blades to detect defects not possible to ?nd at the factory.

Around 3,800 blade failures per year are down to failures to inspect and maintain them at an early stage, according to

ORE Catapult. Another, BladeBug, is a blade walking inspec- tion robot, focusing on leading edge erosion inspection when

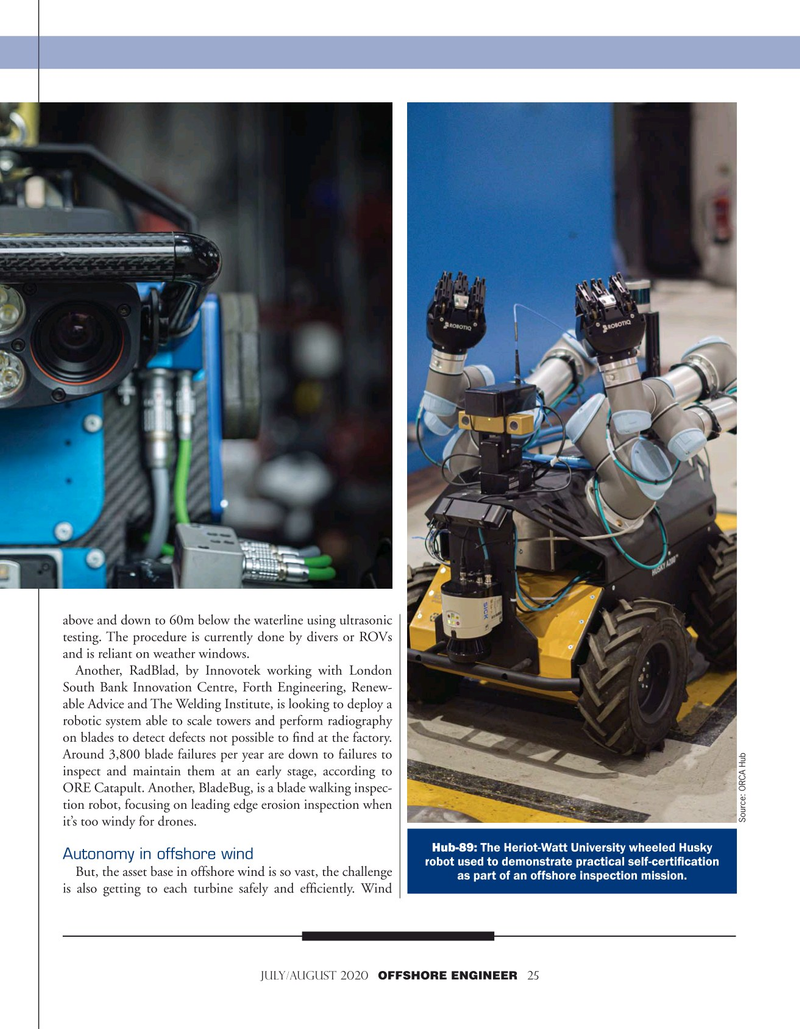

Source: ORCA Hub it’s too windy for drones.

Hub-89: The Heriot-Watt University wheeled Husky

Autonomy in offshore wind

But, the asset base in offshore wind is so vast, the challenge as part of an offshore inspection mission.

is also getting to each turbine safely and ef?ciently. Wind

JULY/AUGUST 2020 OFFSHORE ENGINEER 25

24

24

26

26