Page 41: of Offshore Engineer Magazine (Sep/Oct 2020)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2020 Offshore Engineer Magazine

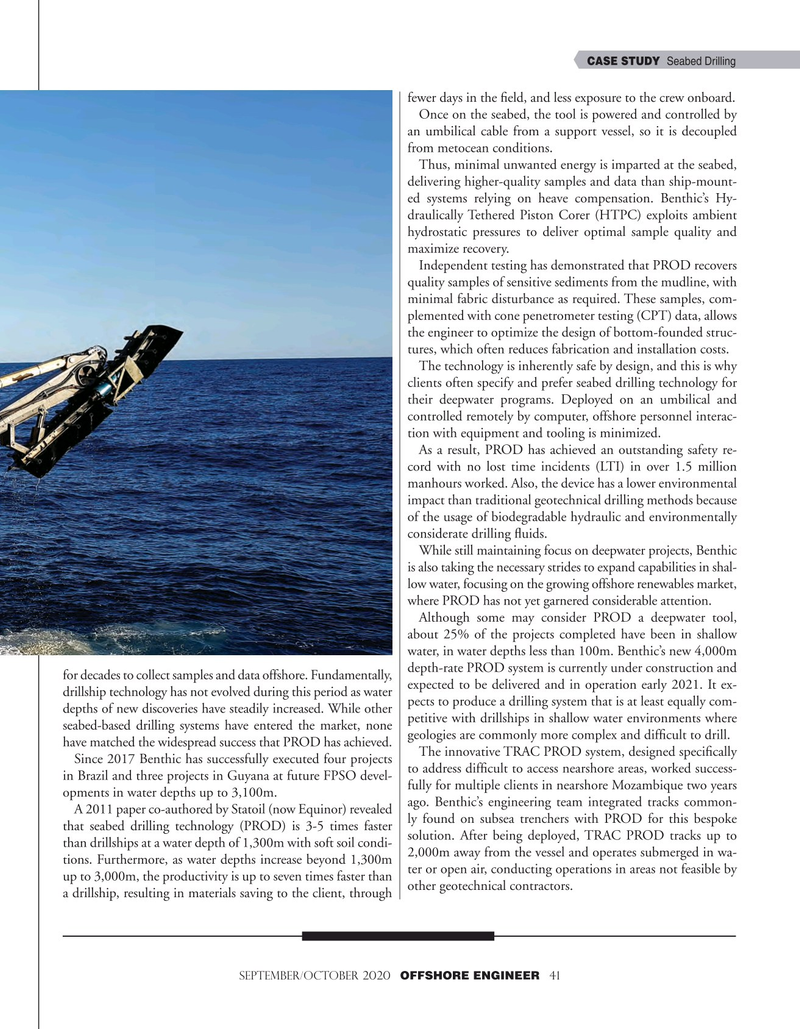

CASE STUDY Seabed Drilling fewer days in the feld, and less exposure to the crew onboard.

Once on the seabed, the tool is powered and controlled by an umbilical cable from a support vessel, so it is decoupled from metocean conditions.

Thus, minimal unwanted energy is imparted at the seabed, delivering higher-quality samples and data than ship-mount- ed systems relying on heave compensation. Benthic’s Hy- draulically Tethered Piston Corer (HTPC) exploits ambient hydrostatic pressures to deliver optimal sample quality and maximize recovery.

Independent testing has demonstrated that PROD recovers quality samples of sensitive sediments from the mudline, with minimal fabric disturbance as required. These samples, com- plemented with cone penetrometer testing (CPT) data, allows the engineer to optimize the design of bottom-founded struc- tures, which often reduces fabrication and installation costs.

The technology is inherently safe by design, and this is why clients often specify and prefer seabed drilling technology for their deepwater programs. Deployed on an umbilical and controlled remotely by computer, offshore personnel interac- tion with equipment and tooling is minimized.

As a result, PROD has achieved an outstanding safety re- cord with no lost time incidents (LTI) in over 1.5 million manhours worked. Also, the device has a lower environmental impact than traditional geotechnical drilling methods because of the usage of biodegradable hydraulic and environmentally considerate drilling fuids.

While still maintaining focus on deepwater projects, Benthic is also taking the necessary strides to expand capabilities in shal- low water, focusing on the growing offshore renewables market, where PROD has not yet garnered considerable attention.

Although some may consider PROD a deepwater tool, about 25% of the projects completed have been in shallow water, in water depths less than 100m. Benthic’s new 4,000m depth-rate PROD system is currently under construction and for decades to collect samples and data offshore. Fundamentally, expected to be delivered and in operation early 2021. It ex- drillship technology has not evolved during this period as water depths of new discoveries have steadily increased. While other pects to produce a drilling system that is at least equally com- seabed-based drilling systems have entered the market, none petitive with drillships in shallow water environments where geologies are commonly more complex and diffcult to drill.

have matched the widespread success that PROD has achieved.

The innovative TRAC PROD system, designed specifcally

Since 2017 Benthic has successfully executed four projects to address diffcult to access nearshore areas, worked success- in Brazil and three projects in Guyana at future FPSO devel- fully for multiple clients in nearshore Mozambique two years opments in water depths up to 3,100m. ago. Benthic’s engineering team integrated tracks common-

A 2011 paper co-authored by Statoil (now Equinor) revealed that seabed drilling technology (PROD) is 3-5 times faster ly found on subsea trenchers with PROD for this bespoke solution. After being deployed, TRAC PROD tracks up to than drillships at a water depth of 1,300m with soft soil condi- tions. Furthermore, as water depths increase beyond 1,300m 2,000m away from the vessel and operates submerged in wa- ter or open air, conducting operations in areas not feasible by up to 3,000m, the productivity is up to seven times faster than a drillship, resulting in materials saving to the client, through other geotechnical contractors.

SEPTEMBER/OCTOBER 2020 OFFSHORE ENGINEER 41

40

40

42

42