Page 20: of Offshore Engineer Magazine (Sep/Oct 2021)

Digital Transformation

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2021 Offshore Engineer Magazine

FPSOs MITIGATING LIFECYCLE RISKS

CONNECTING THE VESSEL lowing main areas of development:

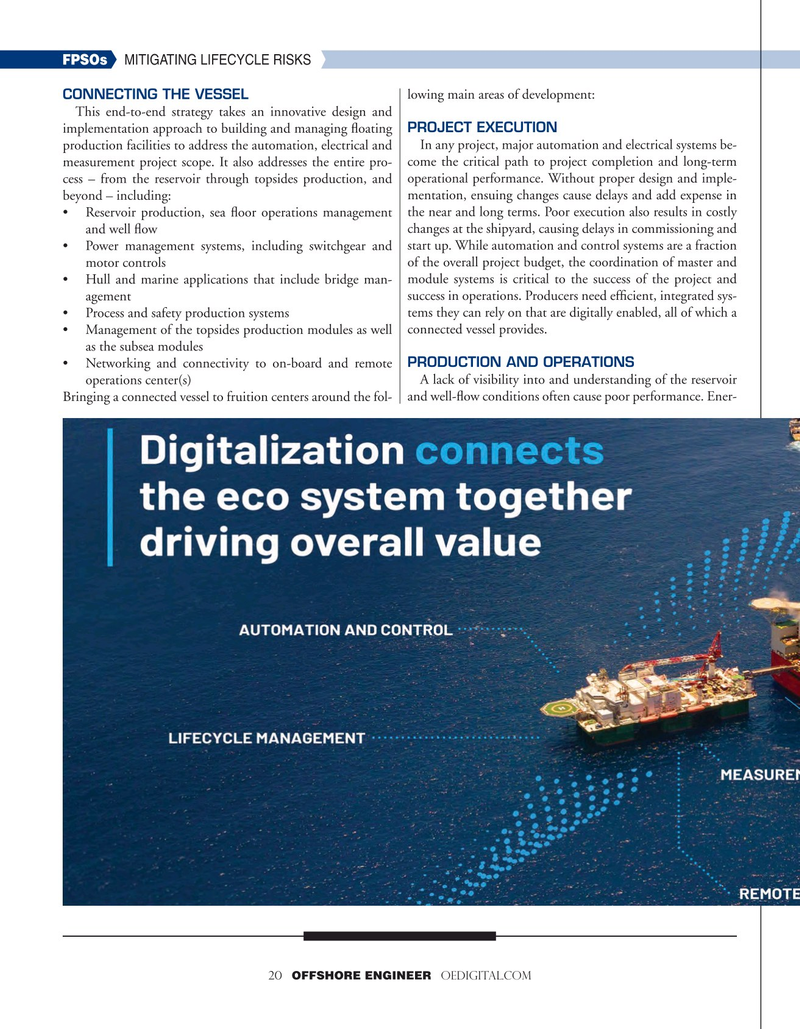

This end-to-end strategy takes an innovative design and implementation approach to building and managing foating PROJECT EXECUTION production facilities to address the automation, electrical and In any project, major automation and electrical systems be- measurement project scope. It also addresses the entire pro- come the critical path to project completion and long-term cess – from the reservoir through topsides production, and operational performance. Without proper design and imple- beyond – including: mentation, ensuing changes cause delays and add expense in • Reservoir production, sea foor operations management the near and long terms. Poor execution also results in costly and well fow changes at the shipyard, causing delays in commissioning and • Power management systems, including switchgear and start up. While automation and control systems are a fraction motor controls of the overall project budget, the coordination of master and • Hull and marine applications that include bridge man- module systems is critical to the success of the project and agement success in operations. Producers need effcient, integrated sys- • Process and safety production systems tems they can rely on that are digitally enabled, all of which a • Management of the topsides production modules as well connected vessel provides.

as the subsea modules • Networking and connectivity to on-board and remote PRODUCTION AND OPERATIONS operations center(s) A lack of visibility into and understanding of the reservoir

Bringing a connected vessel to fruition centers around the fol- and well-fow conditions often cause poor performance. Ener- 20 OFFSHORE ENGINEER OEDIGITAL.COM

19

19

21

21