Page 29: of Offshore Engineer Magazine (Sep/Oct 2021)

Digital Transformation

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2021 Offshore Engineer Magazine

optimize it, Widerøe says. Suppliers would also be brought in to support this work. Sketchup (3D design software) would then be used to create a feld layout, where the wells are, how “We see we’re long the pipelines are, etc. Then a manual process, in Excel, would begin, to cost the project, as well as work on fow assur- able to do double ance, freespan calculations, rocking dumping requirements, the number of etc., that would be done internally and externally in specifc simulations, e.g. Olga, etc. cases, using half “It’s a manual process that takes a lot of time and when the time. And there are more than 200 case books to look into. It takes a lot of time, so there’s little time for iterations. There’s similar data due to better residing within different applications, data residing at con-

FutureOn transparency tractors, quality is questionable, it’s diffcult to keep track of changes, and you’re reliant on individuals. The data residing and standardization and within applications at different companies has to be manually increased communications, updated in each place,” he says.

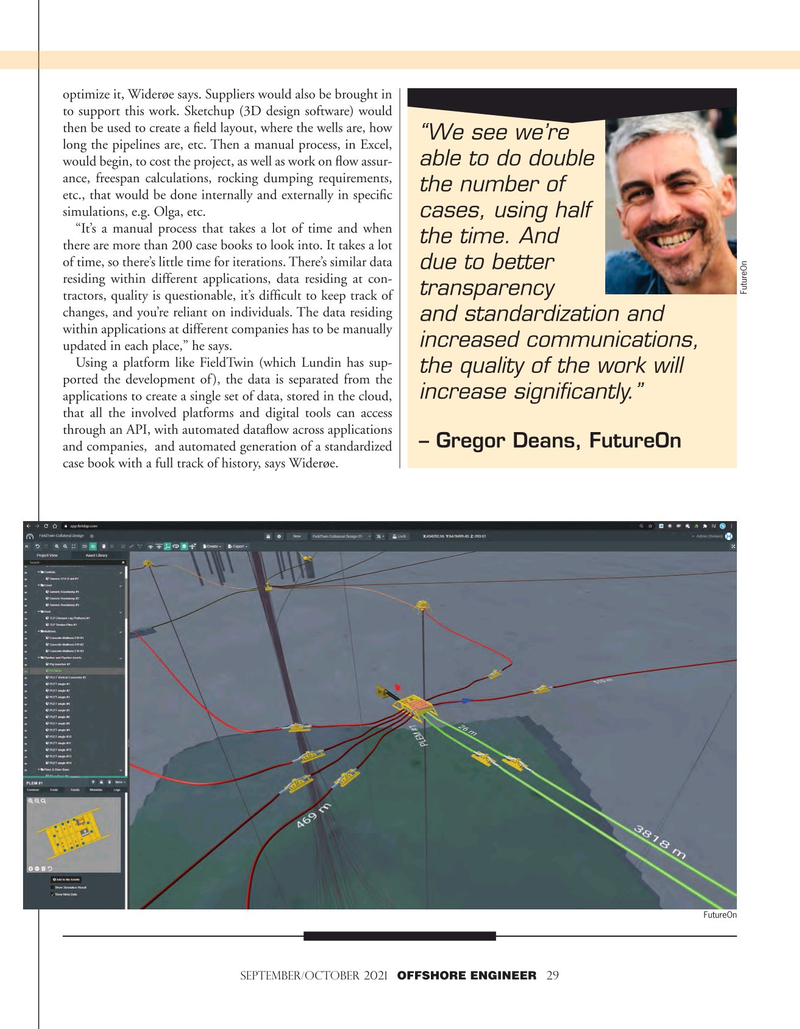

Using a platform like FieldTwin (which Lundin has sup- the quality of the work will ported the development of), the data is separated from the increase significantly.” applications to create a single set of data, stored in the cloud, that all the involved platforms and digital tools can access through an API, with automated datafow across applications – Gregor Deans, FutureOn and companies, and automated generation of a standardized case book with a full track of history, says Widerøe.

FutureOn september/october 2021 OFFSHORE ENGINEER 29

28

28

30

30