Page 23: of Offshore Engineer Magazine (Mar/Apr 2022)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2022 Offshore Engineer Magazine

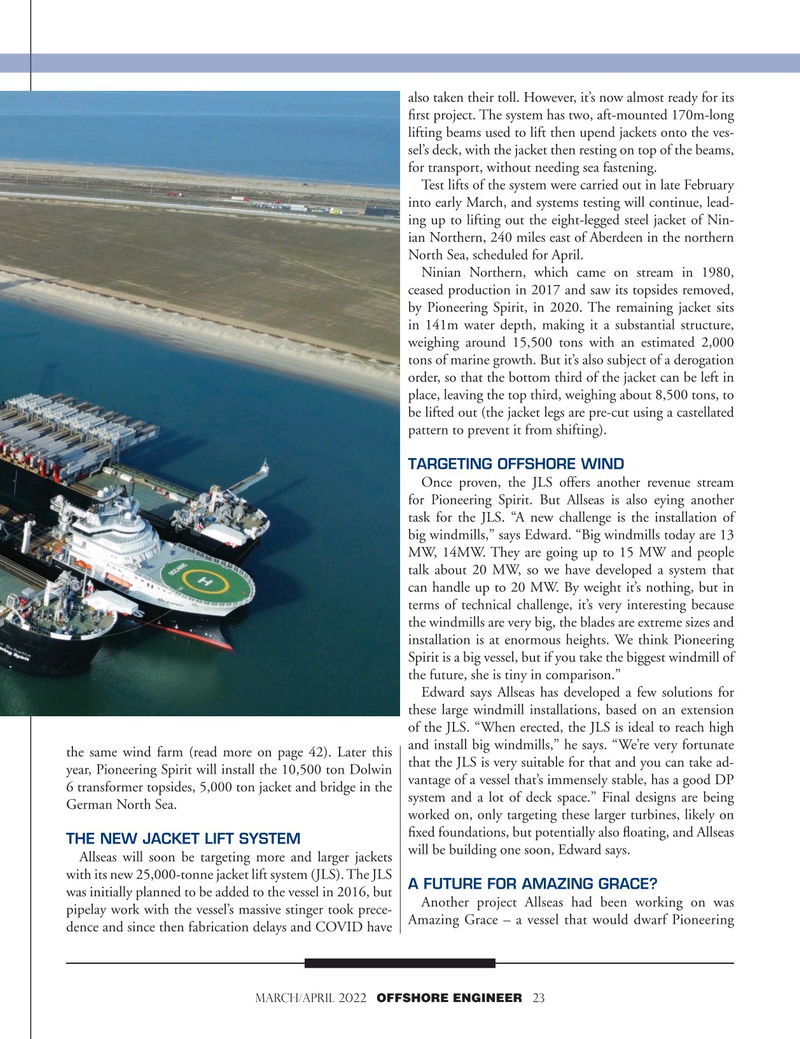

also taken their toll. However, it’s now almost ready for its ? rst project. The system has two, aft-mounted 170m-long lifting beams used to lift then upend jackets onto the ves- sel’s deck, with the jacket then resting on top of the beams, for transport, without needing sea fastening.

Test lifts of the system were carried out in late February into early March, and systems testing will continue, lead- ing up to lifting out the eight-legged steel jacket of Nin- ian Northern, 240 miles east of Aberdeen in the northern

North Sea, scheduled for April.

Ninian Northern, which came on stream in 1980, ceased production in 2017 and saw its topsides removed, by Pioneering Spirit, in 2020. The remaining jacket sits in 141m water depth, making it a substantial structure, weighing around 15,500 tons with an estimated 2,000 tons of marine growth. But it’s also subject of a derogation order, so that the bottom third of the jacket can be left in place, leaving the top third, weighing about 8,500 tons, to be lifted out (the jacket legs are pre-cut using a castellated pattern to prevent it from shifting).

TARGETING OFFSHORE WIND

Once proven, the JLS offers another revenue stream for Pioneering Spirit. But Allseas is also eying another task for the JLS. “A new challenge is the installation of big windmills,” says Edward. “Big windmills today are 13

MW, 14MW. They are going up to 15 MW and people talk about 20 MW, so we have developed a system that can handle up to 20 MW. By weight it’s nothing, but in terms of technical challenge, it’s very interesting because the windmills are very big, the blades are extreme sizes and installation is at enormous heights. We think Pioneering

Spirit is a big vessel, but if you take the biggest windmill of the future, she is tiny in comparison.”

Edward says Allseas has developed a few solutions for these large windmill installations, based on an extension of the JLS. “When erected, the JLS is ideal to reach high the same wind farm (read more on page 42). Later this and install big windmills,” he says. “We’re very fortunate year, Pioneering Spirit will install the 10,500 ton Dolwin that the JLS is very suitable for that and you can take ad- 6 transformer topsides, 5,000 ton jacket and bridge in the vantage of a vessel that’s immensely stable, has a good DP system and a lot of deck space.” Final designs are being

German North Sea. worked on, only targeting these larger turbines, likely on ? xed foundations, but potentially also ? oating, and Allseas

THE NEW JACKET LIFT SYSTEM

Allseas will soon be targeting more and larger jackets will be building one soon, Edward says. with its new 25,000-tonne jacket lift system (JLS). The JLS

A FUTURE FOR AMAZING GRACE? was initially planned to be added to the vessel in 2016, but

Another project Allseas had been working on was pipelay work with the vessel’s massive stinger took prece- dence and since then fabrication delays and COVID have Amazing Grace – a vessel that would dwarf Pioneering march/april 2022 OFFSHORE ENGINEER 23

22

22

24

24