Page 38: of Offshore Engineer Magazine (Mar/Apr 2022)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2022 Offshore Engineer Magazine

PRODUCTION CARBON CAPTURE & STORAGE transportation, utilization and storage. The company of- ? cially pledged to be a part of the broader solution by be- coming a participant in the United Nations Global Com- pact (UNGC), the world’s largest sustainability initiative, in early 2021. The UNGC aligns companies to support its universal principles on human rights, labor, environment and anti-corruption.

NEW APPLICATIONS FOR

PROVEN TECHNOLOGIES

Exceptional engineering delivers solutions that reduce the time, cost, and risk involved in complex processes.

Developing these innovations, however, is anything but simple. It requires the ability to consider challenges from a different point of view and use that perspective to create designs that resolve issues in a novel way.

Dril-Quip used this approach to develop its e-Series products – solutions that fundamentally change some of the ‘norms’ for the oil and gas industry. The company has staked its reputation on these new concepts. And now, building on years of experience and success, including the recent installation of several ‘serial number one’ solutions, it is introducing game-changing technologies for CO2 transportation and storage.

TRANSITIONING INNOVATIONS

FOR CCUS APPLICATIONS tric version provides enhanced long-distance power distri-

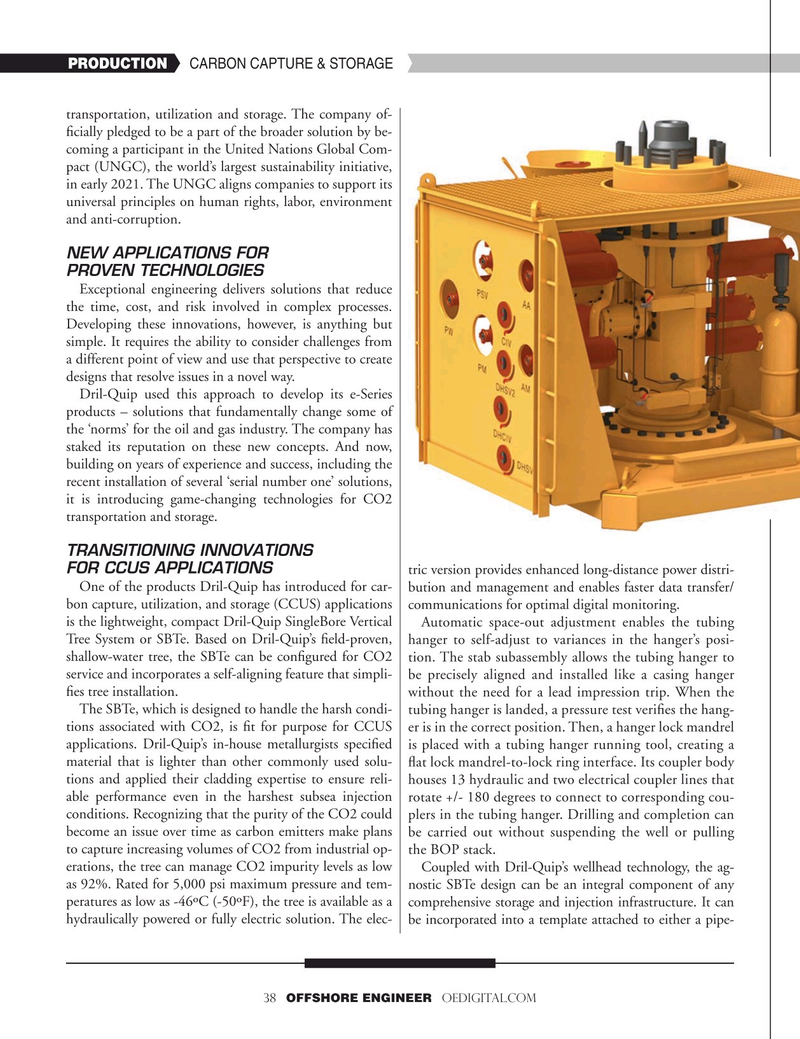

One of the products Dril-Quip has introduced for car- bution and management and enables faster data transfer/ bon capture, utilization, and storage (CCUS) applications communications for optimal digital monitoring.

is the lightweight, compact Dril-Quip SingleBore Vertical Automatic space-out adjustment enables the tubing

Tree System or SBTe. Based on Dril-Quip’s ? eld-proven, hanger to self-adjust to variances in the hanger’s posi- shallow-water tree, the SBTe can be con? gured for CO2 tion. The stab subassembly allows the tubing hanger to service and incorporates a self-aligning feature that simpli- be precisely aligned and installed like a casing hanger ? es tree installation. without the need for a lead impression trip. When the

The SBTe, which is designed to handle the harsh condi- tubing hanger is landed, a pressure test veri? es the hang- tions associated with CO2, is ? t for purpose for CCUS er is in the correct position. Then, a hanger lock mandrel applications. Dril-Quip’s in-house metallurgists speci? ed is placed with a tubing hanger running tool, creating a material that is lighter than other commonly used solu- ? at lock mandrel-to-lock ring interface. Its coupler body tions and applied their cladding expertise to ensure reli- houses 13 hydraulic and two electrical coupler lines that able performance even in the harshest subsea injection rotate +/- 180 degrees to connect to corresponding cou- conditions. Recognizing that the purity of the CO2 could plers in the tubing hanger. Drilling and completion can become an issue over time as carbon emitters make plans be carried out without suspending the well or pulling to capture increasing volumes of CO2 from industrial op- the BOP stack. erations, the tree can manage CO2 impurity levels as low Coupled with Dril-Quip’s wellhead technology, the ag- as 92%. Rated for 5,000 psi maximum pressure and tem- nostic SBTe design can be an integral component of any peratures as low as -46ºC (-50ºF), the tree is available as a comprehensive storage and injection infrastructure. It can hydraulically powered or fully electric solution. The elec- be incorporated into a template attached to either a pipe- 38 OFFSHORE ENGINEER OEDIGITAL.COM

37

37

39

39