Page 36: of Offshore Engineer Magazine (Sep/Oct 2022)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2022 Offshore Engineer Magazine

FEATURE OFFSHORE SOLAR POWER

A KING EIDER DUCK

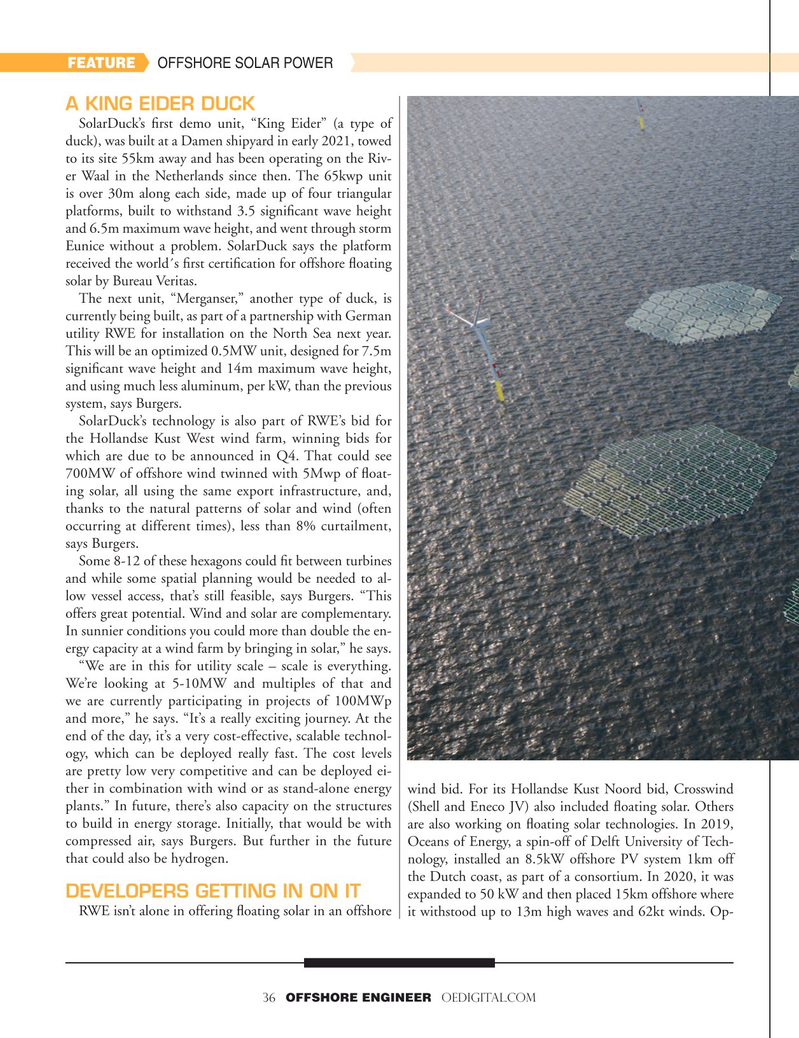

SolarDuck’s frst demo unit, “King Eider” (a type of duck), was built at a Damen shipyard in early 2021, towed to its site 55km away and has been operating on the Riv- er Waal in the Netherlands since then. The 65kwp unit is over 30m along each side, made up of four triangular platforms, built to withstand 3.5 signifcant wave height and 6.5m maximum wave height, and went through storm

Eunice without a problem. SolarDuck says the platform received the world´s frst certifcation for offshore foating solar by Bureau Veritas.

The next unit, “Merganser,” another type of duck, is currently being built, as part of a partnership with German utility RWE for installation on the North Sea next year.

This will be an optimized 0.5MW unit, designed for 7.5m signifcant wave height and 14m maximum wave height, and using much less aluminum, per kW, than the previous system, says Burgers.

SolarDuck’s technology is also part of RWE’s bid for the Hollandse Kust West wind farm, winning bids for which are due to be announced in Q4. That could see 700MW of offshore wind twinned with 5Mwp of foat- ing solar, all using the same export infrastructure, and, thanks to the natural patterns of solar and wind (often occurring at different times), less than 8% curtailment, says Burgers.

Some 8-12 of these hexagons could ft between turbines and while some spatial planning would be needed to al- low vessel access, that’s still feasible, says Burgers. “This offers great potential. Wind and solar are complementary.

In sunnier conditions you could more than double the en- ergy capacity at a wind farm by bringing in solar,” he says. “We are in this for utility scale – scale is everything.

We’re looking at 5-10MW and multiples of that and we are currently participating in projects of 100MWp and more,” he says. “It’s a really exciting journey. At the end of the day, it’s a very cost-effective, scalable technol- ogy, which can be deployed really fast. The cost levels are pretty low very competitive and can be deployed ei- ther in combination with wind or as stand-alone energy wind bid. For its Hollandse Kust Noord bid, Crosswind plants.” In future, there’s also capacity on the structures (Shell and Eneco JV) also included foating solar. Others to build in energy storage. Initially, that would be with are also working on foating solar technologies. In 2019, compressed air, says Burgers. But further in the future Oceans of Energy, a spin-off of Delft University of Tech- that could also be hydrogen. nology, installed an 8.5kW offshore PV system 1km off the Dutch coast, as part of a consortium. In 2020, it was

DEVELOPERS GETTING IN ON IT expanded to 50 kW and then placed 15km offshore where

RWE isn’t alone in offering foating solar in an offshore it withstood up to 13m high waves and 62kt winds. Op- 36 OFFSHORE ENGINEER OEDIGITAL.COM

35

35

37

37