Page 9: of Offshore Engineer Magazine (May/Jun 2023)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2023 Offshore Engineer Magazine

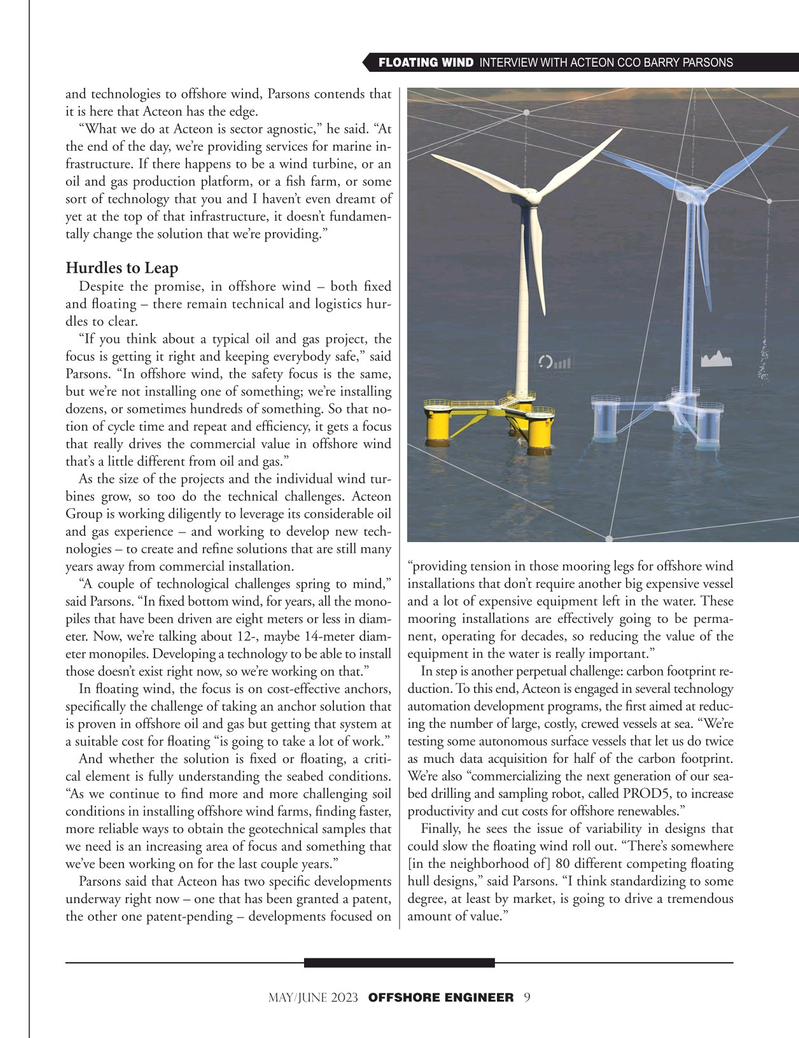

FLOATING WIND INTERVIEW WITH ACTEON CCO BARRY PARSONS and technologies to offshore wind, Parsons contends that it is here that Acteon has the edge.

“What we do at Acteon is sector agnostic,” he said. “At the end of the day, we’re providing services for marine in- frastructure. If there happens to be a wind turbine, or an oil and gas production platform, or a fsh farm, or some sort of technology that you and I haven’t even dreamt of yet at the top of that infrastructure, it doesn’t fundamen- tally change the solution that we’re providing.”

Hurdles to Leap

Despite the promise, in offshore wind – both fxed and foating – there remain technical and logistics hur- dles to clear.

“If you think about a typical oil and gas project, the focus is getting it right and keeping everybody safe,” said

Parsons. “In offshore wind, the safety focus is the same, but we’re not installing one of something; we’re installing dozens, or sometimes hundreds of something. So that no- tion of cycle time and repeat and effciency, it gets a focus that really drives the commercial value in offshore wind that’s a little different from oil and gas.”

As the size of the projects and the individual wind tur- bines grow, so too do the technical challenges. Acteon

Group is working diligently to leverage its considerable oil and gas experience – and working to develop new tech- nologies – to create and refne solutions that are still many years away from commercial installation. “providing tension in those mooring legs for offshore wind “A couple of technological challenges spring to mind,” installations that don’t require another big expensive vessel said Parsons. “In fxed bottom wind, for years, all the mono- and a lot of expensive equipment left in the water. These piles that have been driven are eight meters or less in diam- mooring installations are effectively going to be perma- eter. Now, we’re talking about 12-, maybe 14-meter diam- nent, operating for decades, so reducing the value of the eter monopiles. Developing a technology to be able to install equipment in the water is really important.” those doesn’t exist right now, so we’re working on that.” In step is another perpetual challenge: carbon footprint re-

In foating wind, the focus is on cost-effective anchors, duction. To this end, Acteon is engaged in several technology specifcally the challenge of taking an anchor solution that automation development programs, the frst aimed at reduc- is proven in offshore oil and gas but getting that system at ing the number of large, costly, crewed vessels at sea. “We’re a suitable cost for foating “is going to take a lot of work.” testing some autonomous surface vessels that let us do twice

And whether the solution is fxed or foating, a criti- as much data acquisition for half of the carbon footprint. cal element is fully understanding the seabed conditions. We’re also “commercializing the next generation of our sea- “As we continue to fnd more and more challenging soil bed drilling and sampling robot, called PROD5, to increase conditions in installing offshore wind farms, fnding faster, productivity and cut costs for offshore renewables.” more reliable ways to obtain the geotechnical samples that Finally, he sees the issue of variability in designs that we need is an increasing area of focus and something that could slow the foating wind roll out. “There’s somewhere we’ve been working on for the last couple years.” [in the neighborhood of] 80 different competing foating

Parsons said that Acteon has two specifc developments hull designs,” said Parsons. “I think standardizing to some underway right now – one that has been granted a patent, degree, at least by market, is going to drive a tremendous the other one patent-pending – developments focused on amount of value.”

MAY/JUNE 2023 OFFSHORE ENGINEER 9

8

8

10

10