Page 7: of Offshore Engineer Magazine (Jul/Aug 2023)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2023 Offshore Engineer Magazine

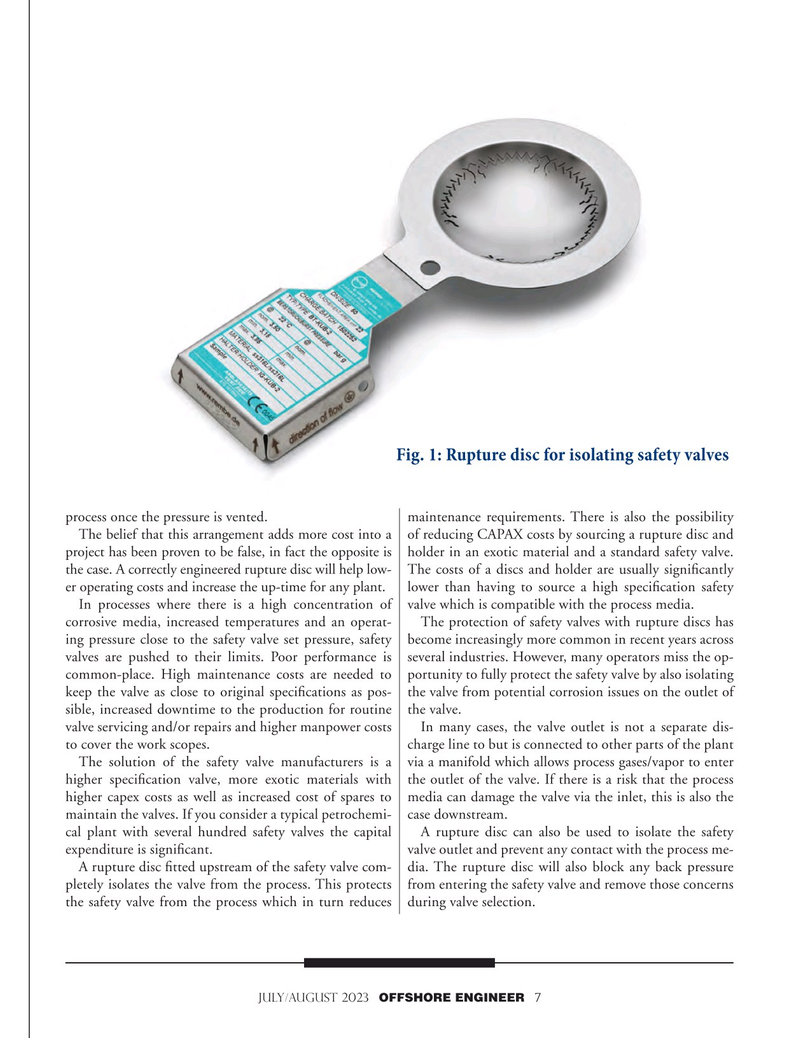

Fig. 1: Rupture disc for isolating safety valves process once the pressure is vented. maintenance requirements. There is also the possibility

The belief that this arrangement adds more cost into a of reducing CAPAX costs by sourcing a rupture disc and project has been proven to be false, in fact the opposite is holder in an exotic material and a standard safety valve. the case. A correctly engineered rupture disc will help low- The costs of a discs and holder are usually signifcantly er operating costs and increase the up-time for any plant. lower than having to source a high specifcation safety

In processes where there is a high concentration of valve which is compatible with the process media.

corrosive media, increased temperatures and an operat- The protection of safety valves with rupture discs has ing pressure close to the safety valve set pressure, safety become increasingly more common in recent years across valves are pushed to their limits. Poor performance is several industries. However, many operators miss the op- common-place. High maintenance costs are needed to portunity to fully protect the safety valve by also isolating keep the valve as close to original specifcations as pos- the valve from potential corrosion issues on the outlet of sible, increased downtime to the production for routine the valve.

valve servicing and/or repairs and higher manpower costs In many cases, the valve outlet is not a separate dis- to cover the work scopes. charge line to but is connected to other parts of the plant

The solution of the safety valve manufacturers is a via a manifold which allows process gases/vapor to enter higher specifcation valve, more exotic materials with the outlet of the valve. If there is a risk that the process higher capex costs as well as increased cost of spares to media can damage the valve via the inlet, this is also the maintain the valves. If you consider a typical petrochemi- case downstream.

cal plant with several hundred safety valves the capital A rupture disc can also be used to isolate the safety expenditure is signifcant. valve outlet and prevent any contact with the process me-

A rupture disc ftted upstream of the safety valve com- dia. The rupture disc will also block any back pressure pletely isolates the valve from the process. This protects from entering the safety valve and remove those concerns the safety valve from the process which in turn reduces during valve selection.

july/august 2023 OFFSHORE ENGINEER 7

6

6

8

8