Page 28: of Offshore Engineer Magazine (Sep/Oct 2023)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2023 Offshore Engineer Magazine

an increasing number of European clean energy projects are looking at the production of green hydrogen and pow- er-to-X fuels such as ammonia on ?oating platforms.

In a study of the North and Baltic Seas, DNV concluded that the lower costs of hydrogen transmission compared to electricity and the possibility for large pipelines to ag- gregate offshore hydrogen production from several wind- farms, makes offshore hydrogen production an attractive option for offshore wind farms, certainly at distances of more than 100 kilometers from shore.

The alternative is shipping molecules to shore, and Ma- ciek Lukawski, VP of Strategy & Business Development for ammonia power solutions company Amogy, points out that, for locations like Japan, Europe and the US with lim- ited shallow waters and strong interest in ammonia, ?oating production platforms will enable strategic access to clean ammonia. “Transportation of green ammonia through shipping can provide widespread access in the near future rather than the development of offshore pipelines.” Amo- gy has signed MoUs with Southwind to promote offshore wind development and Marco Polo Marine to develop its ammonia-to-power solution for deployment on OSVs.

Shipping will still involve new piping solutions. Earlier this year, H2Carrier and Trelleborg Gas Transfer signed an

MoU on ship-to-ship ammonia transfer systems that will be based on Trelleborg’s KLAW LNG technology and up- graded to operate with liquid ammonia.

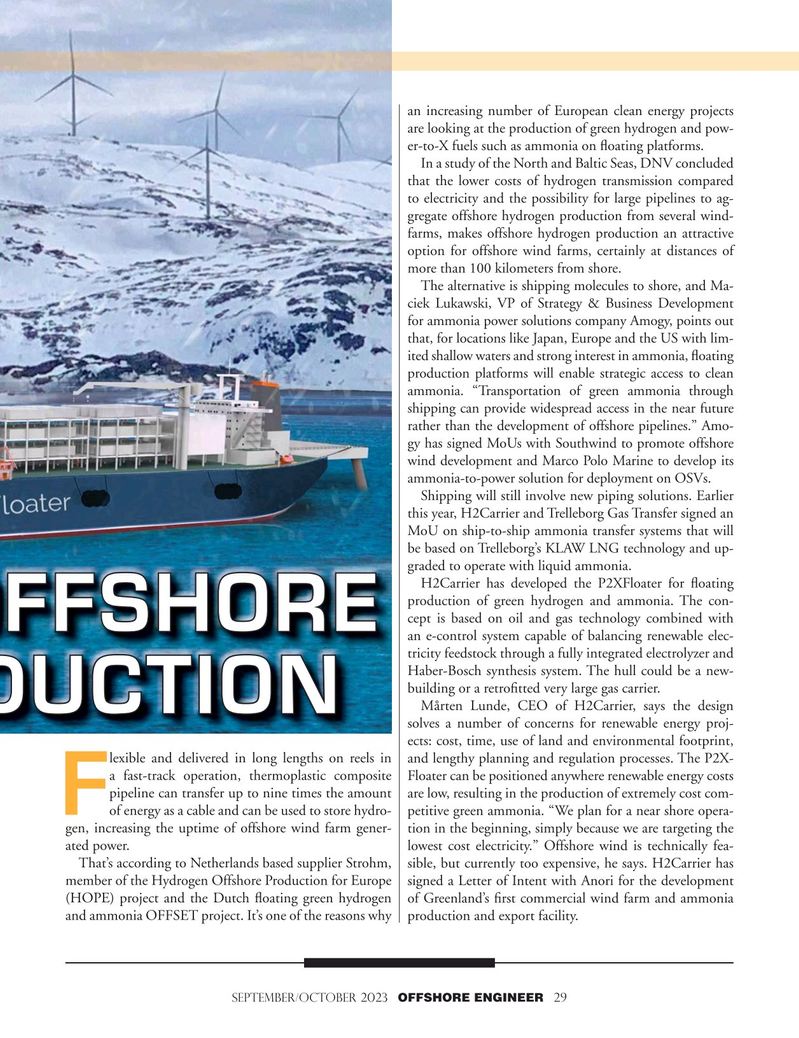

H2Carrier has developed the P2XFloater for ?oating production of green hydrogen and ammonia. The con- cept is based on oil and gas technology combined with

FFSHORE an e-control system capable of balancing renewable elec- tricity feedstock through a fully integrated electrolyzer and

Haber-Bosch synthesis system. The hull could be a new- building or a retro?tted very large gas carrier.

Mårten Lunde, CEO of H2Carrier, says the design

DUCTION solves a number of concerns for renewable energy proj- ects: cost, time, use of land and environmental footprint, lexible and delivered in long lengths on reels in and lengthy planning and regulation processes. The P2X- a fast-track operation, thermoplastic composite Floater can be positioned anywhere renewable energy costs pipeline can transfer up to nine times the amount are low, resulting in the production of extremely cost com-

F of energy as a cable and can be used to store hydro- petitive green ammonia. “We plan for a near shore opera- gen, increasing the uptime of offshore wind farm gener- tion in the beginning, simply because we are targeting the ated power. lowest cost electricity.” Offshore wind is technically fea-

That’s according to Netherlands based supplier Strohm, sible, but currently too expensive, he says. H2Carrier has member of the Hydrogen Offshore Production for Europe signed a Letter of Intent with Anori for the development (HOPE) project and the Dutch ?oating green hydrogen of Greenland’s ?rst commercial wind farm and ammonia and ammonia OFFSET project. It’s one of the reasons why production and export facility.

september/october 2023 OFFSHORE ENGINEER 29

27

27

29

29