Page 37: of Offshore Engineer Magazine (Nov/Dec 2023)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2023 Offshore Engineer Magazine

Also, the maintenance and change out operations are “Further, we also have the drill foor completely fush planned to be completely done out of the critical path and with the main deck and therefore mobilizing of equipment in many cases even onshore. is much, much easier, and therefore saving time, and there- “So, you ship pieces of equipment onshore, do the fore saving costs as well.

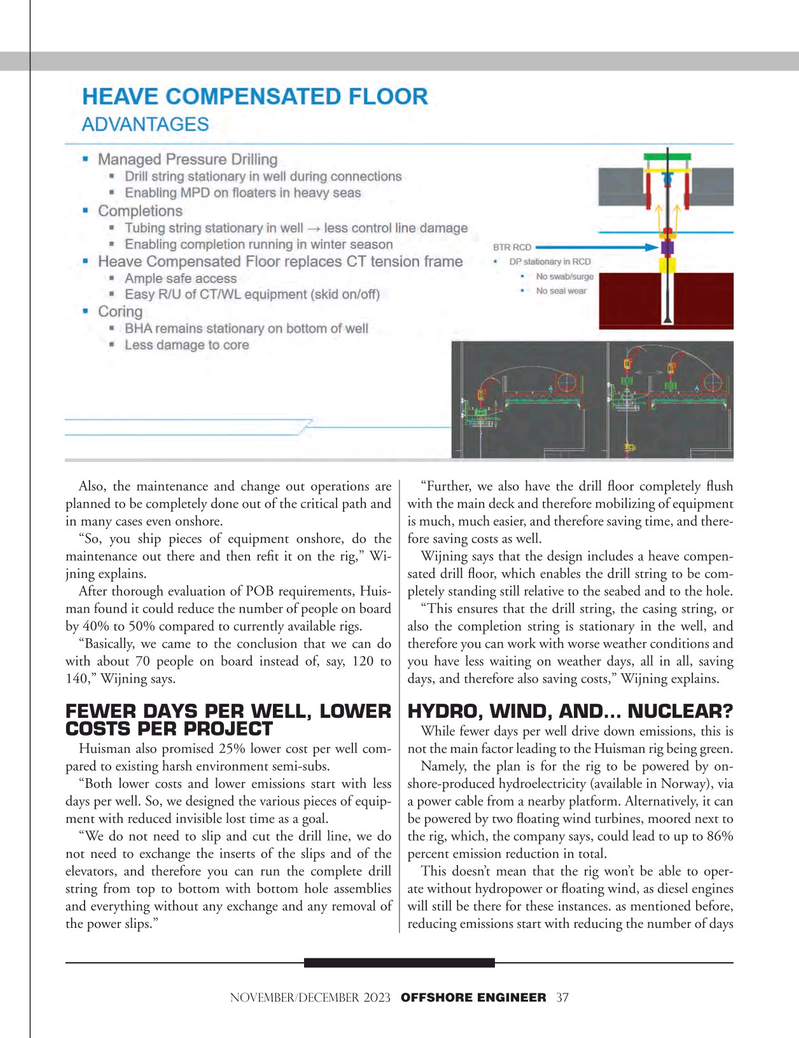

maintenance out there and then reft it on the rig,” Wi- Wijning says that the design includes a heave compen- jning explains. sated drill foor, which enables the drill string to be com-

After thorough evaluation of POB requirements, Huis- pletely standing still relative to the seabed and to the hole. man found it could reduce the number of people on board “This ensures that the drill string, the casing string, or by 40% to 50% compared to currently available rigs. also the completion string is stationary in the well, and “Basically, we came to the conclusion that we can do therefore you can work with worse weather conditions and with about 70 people on board instead of, say, 120 to you have less waiting on weather days, all in all, saving 140,” Wijning says. days, and therefore also saving costs,” Wijning explains.

FEWER DAYS PER WELL, LOWER HYDRO, WIND, AND… NUCLEAR?

While fewer days per well drive down emissions, this is

COSTS PER PROJECT

Huisman also promised 25% lower cost per well com- not the main factor leading to the Huisman rig being green. pared to existing harsh environment semi-subs. Namely, the plan is for the rig to be powered by on- “Both lower costs and lower emissions start with less shore-produced hydroelectricity (available in Norway), via days per well. So, we designed the various pieces of equip- a power cable from a nearby platform. Alternatively, it can ment with reduced invisible lost time as a goal. be powered by two foating wind turbines, moored next to “We do not need to slip and cut the drill line, we do the rig, which, the company says, could lead to up to 86% not need to exchange the inserts of the slips and of the percent emission reduction in total.

elevators, and therefore you can run the complete drill This doesn’t mean that the rig won’t be able to oper- string from top to bottom with bottom hole assemblies ate without hydropower or foating wind, as diesel engines and everything without any exchange and any removal of will still be there for these instances. as mentioned before, the power slips.” reducing emissions start with reducing the number of days november/december 2023 OFFSHORE ENGINEER 37

36

36

38

38