Page 46: of Offshore Engineer Magazine (Jul/Aug 2024)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2024 Offshore Engineer Magazine

TECH TALK HYDROGEN

SwitcH2

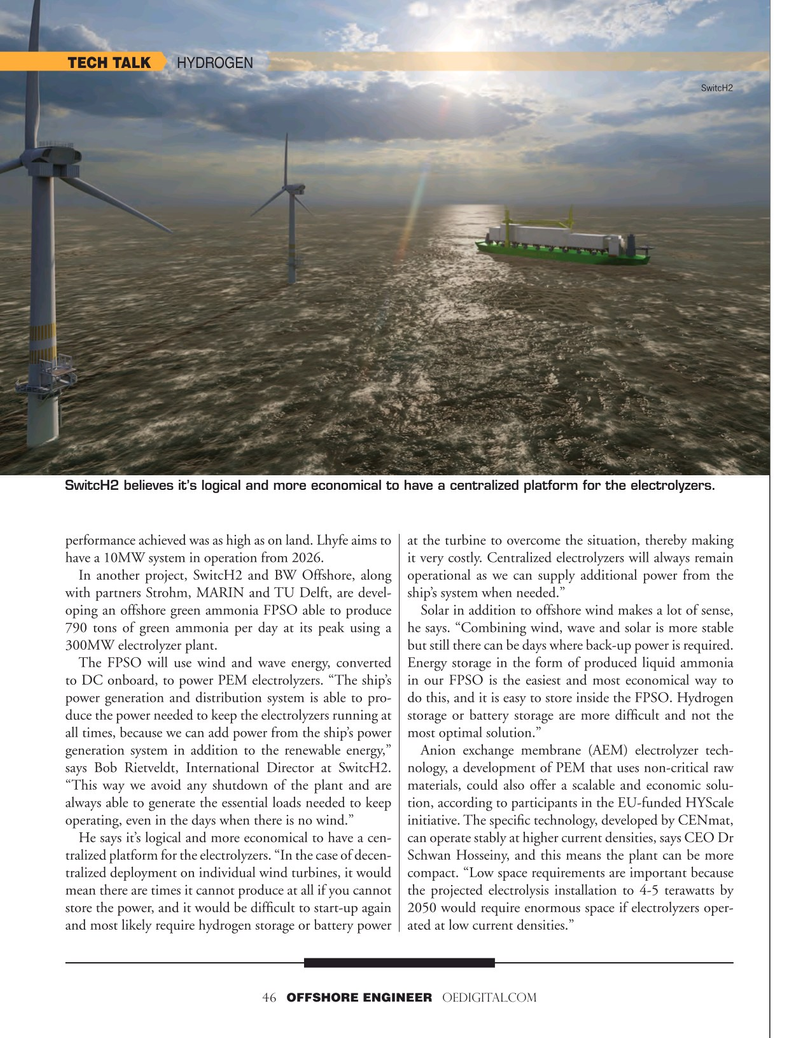

SwitcH2 believes it’s logical and more economical to have a centralized platform for the electrolyzers. performance achieved was as high as on land. Lhyfe aims to at the turbine to overcome the situation, thereby making have a 10MW system in operation from 2026. it very costly. Centralized electrolyzers will always remain

In another project, SwitcH2 and BW Offshore, along operational as we can supply additional power from the with partners Strohm, MARIN and TU Delft, are devel- ship’s system when needed.” oping an offshore green ammonia FPSO able to produce Solar in addition to offshore wind makes a lot of sense, 790 tons of green ammonia per day at its peak using a he says. “Combining wind, wave and solar is more stable 300MW electrolyzer plant. but still there can be days where back-up power is required.

The FPSO will use wind and wave energy, converted Energy storage in the form of produced liquid ammonia to DC onboard, to power PEM electrolyzers. “The ship’s in our FPSO is the easiest and most economical way to power generation and distribution system is able to pro- do this, and it is easy to store inside the FPSO. Hydrogen duce the power needed to keep the electrolyzers running at storage or battery storage are more diffcult and not the all times, because we can add power from the ship’s power most optimal solution.” generation system in addition to the renewable energy,” Anion exchange membrane (AEM) electrolyzer tech- says Bob Rietveldt, International Director at SwitcH2. nology, a development of PEM that uses non-critical raw “This way we avoid any shutdown of the plant and are materials, could also offer a scalable and economic solu- always able to generate the essential loads needed to keep tion, according to participants in the EU-funded HYScale operating, even in the days when there is no wind.” initiative. The specifc technology, developed by CENmat,

He says it’s logical and more economical to have a cen- can operate stably at higher current densities, says CEO Dr tralized platform for the electrolyzers. “In the case of decen- Schwan Hosseiny, and this means the plant can be more tralized deployment on individual wind turbines, it would compact. “Low space requirements are important because mean there are times it cannot produce at all if you cannot the projected electrolysis installation to 4-5 terawatts by store the power, and it would be diffcult to start-up again 2050 would require enormous space if electrolyzers oper- and most likely require hydrogen storage or battery power ated at low current densities.” 46 OFFSHORE ENGINEER OEDIGITAL.COM

45

45

47

47