Page 50: of Offshore Engineer Magazine (Mar/Apr 2025)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2025 Offshore Engineer Magazine

ROBOTICS INSPECTION, MAINTENANCE & REPAIR

Images courtesy Oceaneering

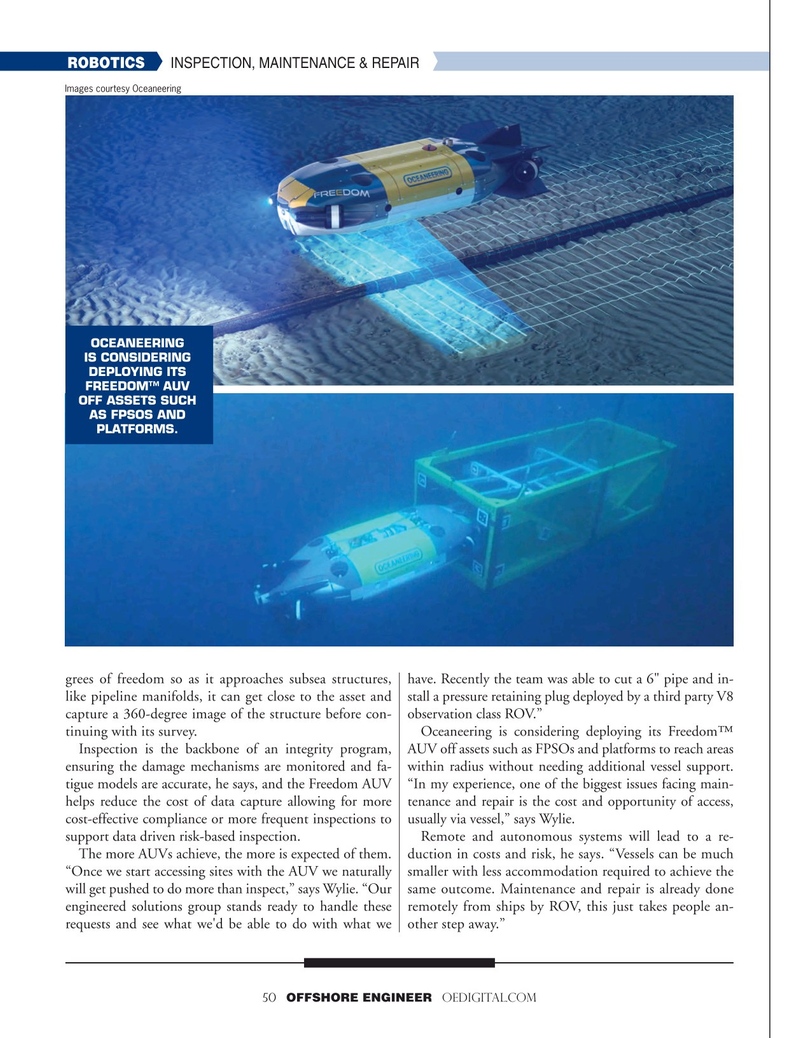

OCEANEERING

IS CONSIDERING

DEPLOYING ITS

FREEDOM™ AUV

OFF ASSETS SUCH

AS FPSOS AND

PLATFORMS.

grees of freedom so as it approaches subsea structures, have. Recently the team was able to cut a 6" pipe and in- like pipeline manifolds, it can get close to the asset and stall a pressure retaining plug deployed by a third party V8 capture a 360-degree image of the structure before con- observation class ROV.” tinuing with its survey. Oceaneering is considering deploying its Freedom™

Inspection is the backbone of an integrity program, AUV off assets such as FPSOs and platforms to reach areas ensuring the damage mechanisms are monitored and fa- within radius without needing additional vessel support. tigue models are accurate, he says, and the Freedom AUV “In my experience, one of the biggest issues facing main- helps reduce the cost of data capture allowing for more tenance and repair is the cost and opportunity of access, cost-effective compliance or more frequent inspections to usually via vessel,” says Wylie. support data driven risk-based inspection. Remote and autonomous systems will lead to a re-

The more AUVs achieve, the more is expected of them. duction in costs and risk, he says. “Vessels can be much “Once we start accessing sites with the AUV we naturally smaller with less accommodation required to achieve the will get pushed to do more than inspect,” says Wylie. “Our same outcome. Maintenance and repair is already done engineered solutions group stands ready to handle these remotely from ships by ROV, this just takes people an- requests and see what we'd be able to do with what we other step away.” 50 OFFSHORE ENGINEER OEDIGITAL.COM

49

49

51

51