Page 58: of Offshore Engineer Magazine (Mar/Apr 2025)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2025 Offshore Engineer Magazine

DEEPWATER MANAGED PRESSURE DRILLING

Components and Functions of the Below-Tension-Ring Rotating Control

Integrated Riser Joint System Device (BTR-RCD)

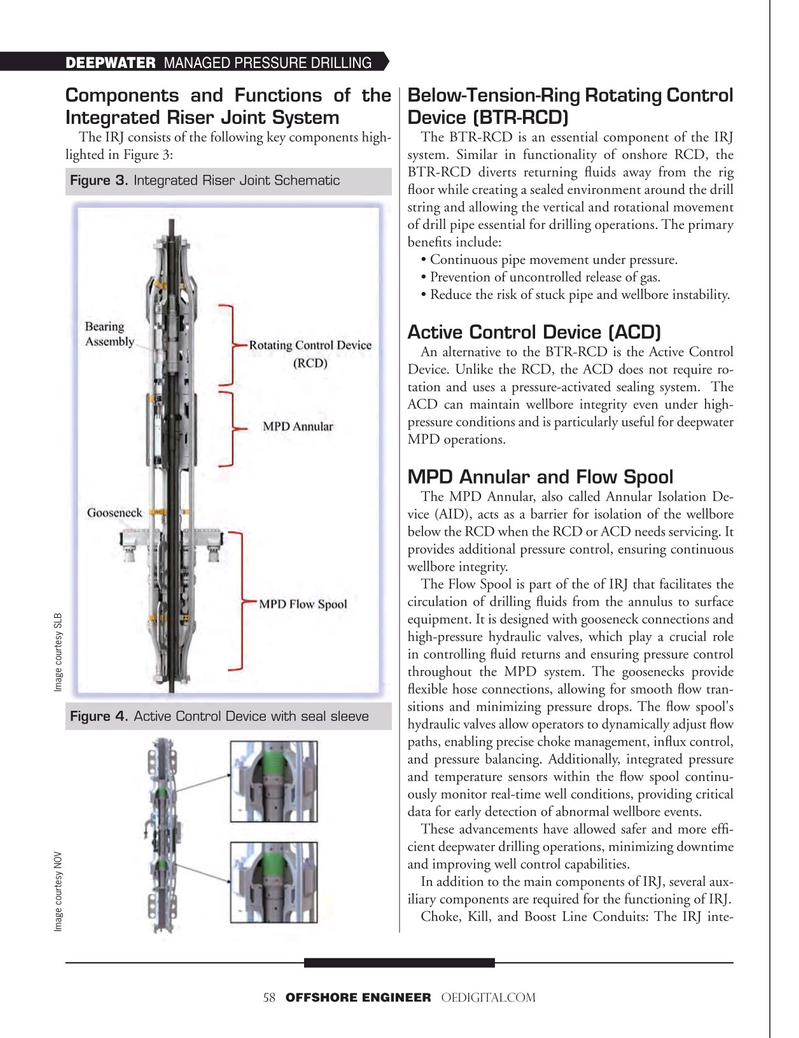

The IRJ consists of the following key components high- The BTR-RCD is an essential component of the IRJ lighted in Figure 3: system. Similar in functionality of onshore RCD, the

BTR-RCD diverts returning fuids away from the rig

Figure 3. Integrated Riser Joint Schematic foor while creating a sealed environment around the drill string and allowing the vertical and rotational movement of drill pipe essential for drilling operations. The primary benefts include: • Continuous pipe movement under pressure.

• Prevention of uncontrolled release of gas. • Reduce the risk of stuck pipe and wellbore instability.

Active Control Device (ACD)

An alternative to the BTR-RCD is the Active Control

Device. Unlike the RCD, the ACD does not require ro- tation and uses a pressure-activated sealing system. The

ACD can maintain wellbore integrity even under high- pressure conditions and is particularly useful for deepwater

MPD operations.

MPD Annular and Flow Spool

The MPD Annular, also called Annular Isolation De- vice (AID), acts as a barrier for isolation of the wellbore below the RCD when the RCD or ACD needs servicing. It provides additional pressure control, ensuring continuous wellbore integrity.

The Flow Spool is part of the of IRJ that facilitates the circulation of drilling fuids from the annulus to surface equipment. It is designed with gooseneck connections and high-pressure hydraulic valves, which play a crucial role in controlling fuid returns and ensuring pressure control throughout the MPD system. The goosenecks provide fexible hose connections, allowing for smooth fow tran- sitions and minimizing pressure drops. The fow spool's

Figure 4. Active Control Device with seal sleeve hydraulic valves allow operators to dynamically adjust fow paths, enabling precise choke management, infux control, and pressure balancing. Additionally, integrated pressure and temperature sensors within the fow spool continu- ously monitor real-time well conditions, providing critical data for early detection of abnormal wellbore events.

These advancements have allowed safer and more eff- cient deepwater drilling operations, minimizing downtime and improving well control capabilities.

In addition to the main components of IRJ, several aux- iliary components are required for the functioning of IRJ.

Choke, Kill, and Boost Line Conduits: The IRJ inte-

Image courtesy NOV Image courtesy SLB 58 OFFSHORE ENGINEER OEDIGITAL.COM

57

57

59

59