Page 23: of Offshore Engineer Magazine (Jul/Aug 2025)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2025 Offshore Engineer Magazine

JOHAN CASTBERG PROJECT OVERVIEW SATISFYING STRINGENT EMISSIONS

Johan Castberg is Norway’s most northerly Arctic feld REQUIREMENTS development project and is located roughly 240 kilometers Gas turbines specifed for offshore applications are ex- northwest of Hammerfest. The development concept in- pected to operate reliability on a wide range of fuel com- cludes 30 wells distributed across ten subsea templates and positions, often with calorifc values considerably different 2 two satellites that will be tied back to the FPSO. According from standard pipeline gas . For this reason, the majority to Equinor, production rates from the feld could reach up of gas turbines installed offshore utilize non-dry low emis- 1 to 220,000 barrels per day at the peak . sions (DLE) combustion technology, which generally is

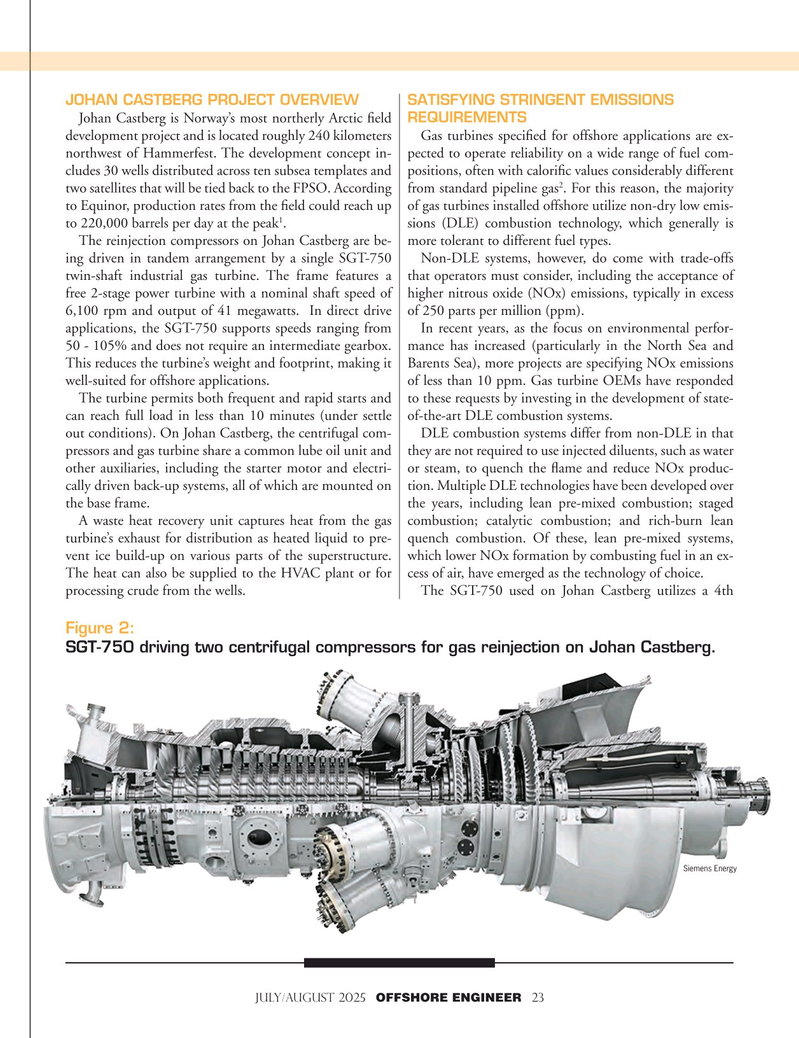

The reinjection compressors on Johan Castberg are be- more tolerant to different fuel types. ing driven in tandem arrangement by a single SGT-750 Non-DLE systems, however, do come with trade-offs twin-shaft industrial gas turbine. The frame features a that operators must consider, including the acceptance of free 2-stage power turbine with a nominal shaft speed of higher nitrous oxide (NOx) emissions, typically in excess 6,100 rpm and output of 41 megawatts. In direct drive of 250 parts per million (ppm).

applications, the SGT-750 supports speeds ranging from In recent years, as the focus on environmental perfor- 50 - 105% and does not require an intermediate gearbox. mance has increased (particularly in the North Sea and

This reduces the turbine’s weight and footprint, making it Barents Sea), more projects are specifying NOx emissions well-suited for offshore applications. of less than 10 ppm. Gas turbine OEMs have responded

The turbine permits both frequent and rapid starts and to these requests by investing in the development of state- can reach full load in less than 10 minutes (under settle of-the-art DLE combustion systems. out conditions). On Johan Castberg, the centrifugal com- DLE combustion systems differ from non-DLE in that pressors and gas turbine share a common lube oil unit and they are not required to use injected diluents, such as water other auxiliaries, including the starter motor and electri- or steam, to quench the fame and reduce NOx produc- cally driven back-up systems, all of which are mounted on tion. Multiple DLE technologies have been developed over the base frame. the years, including lean pre-mixed combustion; staged

A waste heat recovery unit captures heat from the gas combustion; catalytic combustion; and rich-burn lean turbine’s exhaust for distribution as heated liquid to pre- quench combustion. Of these, lean pre-mixed systems, vent ice build-up on various parts of the superstructure. which lower NOx formation by combusting fuel in an ex-

The heat can also be supplied to the HVAC plant or for cess of air, have emerged as the technology of choice. processing crude from the wells. The SGT-750 used on Johan Castberg utilizes a 4th

Figure 2:

SGT-750 driving two centrifugal compressors for gas reinjection on Johan Castberg.

Siemens Energy

JULY/AUGUST 2025 OFFSHORE ENGINEER 23

22

22

24

24