Page 41: of Offshore Engineer Magazine (Jul/Aug 2025)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2025 Offshore Engineer Magazine

arine engineering is currently undergo- based applications where systems are subjected to fuctuat- ing a transformation where effciency, ing loads, variable speeds, and harsh environments daily. reliability, and sustainability are under a In these circumstances, the right coupling can mean the microscope — and companies are look- difference between smooth sailing and costly downtime of

M ing to fnd any and all operational im- an expensive asset. provements. Within this context, fexible couplings play a humble yet pivotal role in these advancements. Often- COMMON TYPES OF MARINE COUPLINGS times overlooked, these components enable all types of Marine power transmission systems rely on a variety marine power transmission by quietly absorbing shock of fexible coupling styles designed to meet particular de- loads, damping noise, compensating for misalignment mands for varying operations. Metallic fexible coupling and relative motions in the powertrain, and most critically, styles, like gear tooth and disc pack designs, are known controlling harmful torsional vibration. for their high torque capacity and compact design. They

As vessels evolve to meet new environmental and opera- are most often used in places where misalignment is mini- tional demands, fexible coupling technologies are emerg- mal, and space may be limited (especially in diameter). A ing as key enablers of performance and innovation. downside to gear tooth designs is that they do require pe- riodic lubrication, where disc pack couplings are relatively

UNDERSTANDING THE ROLE OF maintenance free.

A FLEXIBLE COUPLING Elastomeric couplings, on the other hand, are better

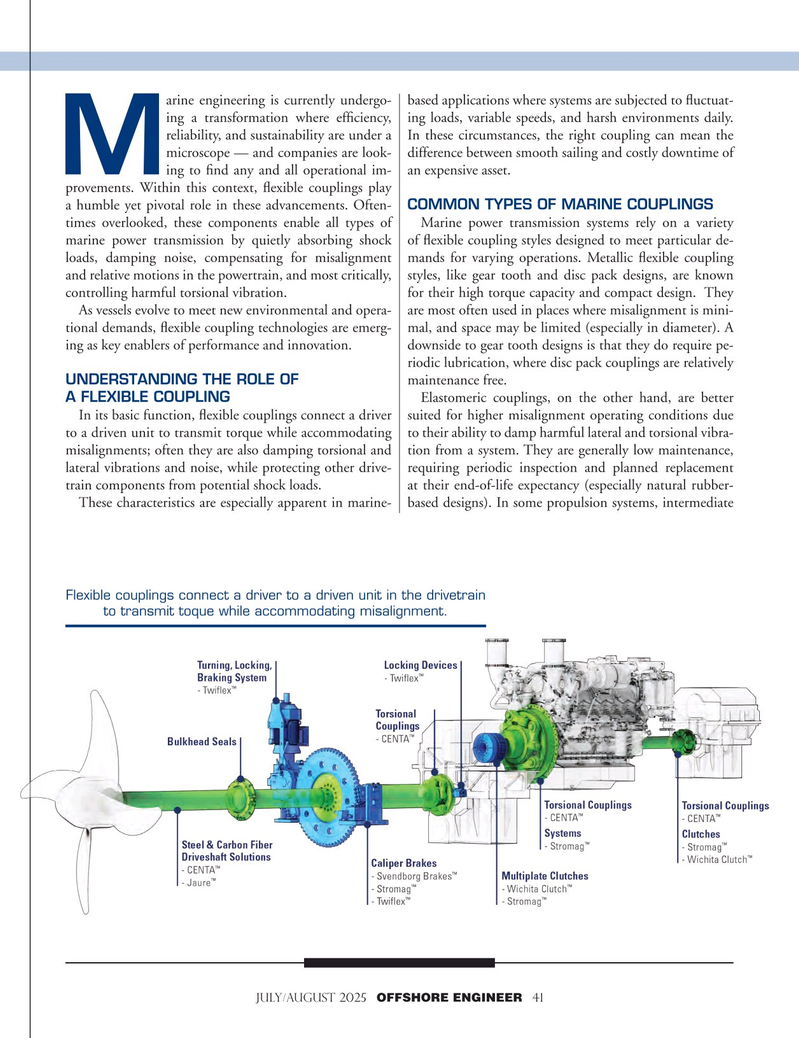

In its basic function, fexible couplings connect a driver suited for higher misalignment operating conditions due to a driven unit to transmit torque while accommodating to their ability to damp harmful lateral and torsional vibra- misalignments; often they are also damping torsional and tion from a system. They are generally low maintenance, lateral vibrations and noise, while protecting other drive- requiring periodic inspection and planned replacement train components from potential shock loads. at their end-of-life expectancy (especially natural rubber-

These characteristics are especially apparent in marine- based designs). In some propulsion systems, intermediate

Flexible couplings connect a driver to a driven unit in the drivetrain to transmit toque while accommodating misalignment.

JULY/AUGUST 2025 OFFSHORE ENGINEER 41

40

40

42

42