Page 44: of Marine News Magazine (May 2015)

Offshore Annual

Read this page in Pdf, Flash or Html5 edition of May 2015 Marine News Magazine

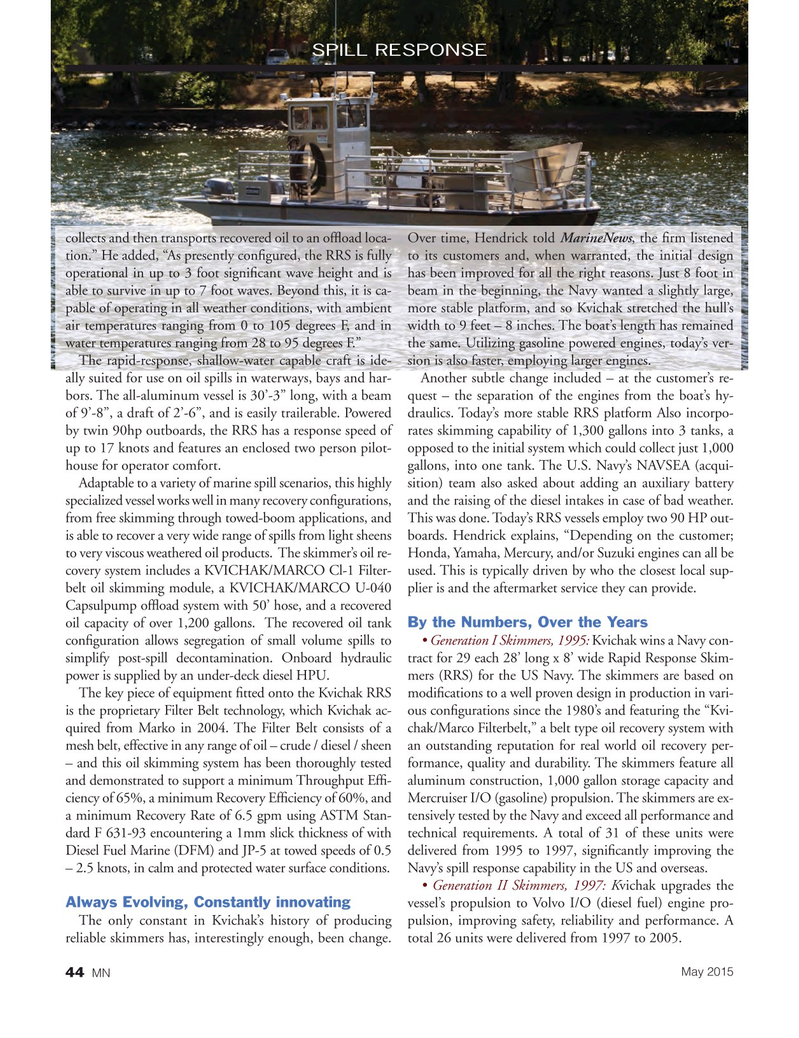

SPILL RESPONSE collects and then transports recovered oil to an of? oad loca- Over time, Hendrick told MarineNews, the ? rm listened tion.” He added, “As presently con? gured, the RRS is fully to its customers and, when warranted, the initial design operational in up to 3 foot signi? cant wave height and is has been improved for all the right reasons. Just 8 foot in able to survive in up to 7 foot waves. Beyond this, it is ca- beam in the beginning, the Navy wanted a slightly large, pable of operating in all weather conditions, with ambient more stable platform, and so Kvichak stretched the hull’s air temperatures ranging from 0 to 105 degrees F, and in width to 9 feet – 8 inches. The boat’s length has remained water temperatures ranging from 28 to 95 degrees F.” the same. Utilizing gasoline powered engines, today’s ver-

The rapid-response, shallow-water capable craft is ide- sion is also faster, employing larger engines.

ally suited for use on oil spills in waterways, bays and har- Another subtle change included – at the customer’s re- bors. The all-aluminum vessel is 30’-3” long, with a beam quest – the separation of the engines from the boat’s hy- of 9’-8”, a draft of 2’-6”, and is easily trailerable. Powered draulics. Today’s more stable RRS platform Also incorpo- by twin 90hp outboards, the RRS has a response speed of rates skimming capability of 1,300 gallons into 3 tanks, a up to 17 knots and features an enclosed two person pilot- opposed to the initial system which could collect just 1,000 house for operator comfort. gallons, into one tank. The U.S. Navy’s NAVSEA (acqui-

Adaptable to a variety of marine spill scenarios, this highly sition) team also asked about adding an auxiliary battery specialized vessel works well in many recovery con? gurations, and the raising of the diesel intakes in case of bad weather. from free skimming through towed-boom applications, and This was done. Today’s RRS vessels employ two 90 HP out- is able to recover a very wide range of spills from light sheens boards. Hendrick explains, “Depending on the customer; to very viscous weathered oil products. The skimmer’s oil re- Honda, Yamaha, Mercury, and/or Suzuki engines can all be covery system includes a KVICHAK/MARCO Cl-1 Filter- used. This is typically driven by who the closest local sup- belt oil skimming module, a KVICHAK/MARCO U-040 plier is and the aftermarket service they can provide.

Capsulpump of? oad system with 50’ hose, and a recovered oil capacity of over 1,200 gallons. The recovered oil tank By the Numbers, Over the Years con? guration allows segregation of small volume spills to • Generation I Skimmers, 1995: Kvichak wins a Navy con- simplify post-spill decontamination. Onboard hydraulic tract for 29 each 28’ long x 8’ wide Rapid Response Skim- power is supplied by an under-deck diesel HPU. mers (RRS) for the US Navy. The skimmers are based on

The key piece of equipment ? tted onto the Kvichak RRS modi? cations to a well proven design in production in vari- is the proprietary Filter Belt technology, which Kvichak ac- ous con? gurations since the 1980’s and featuring the “Kvi- quired from Marko in 2004. The Filter Belt consists of a chak/Marco Filterbelt,” a belt type oil recovery system with mesh belt, effective in any range of oil – crude / diesel / sheen an outstanding reputation for real world oil recovery per- – and this oil skimming system has been thoroughly tested formance, quality and durability. The skimmers feature all and demonstrated to support a minimum Throughput Ef? - aluminum construction, 1,000 gallon storage capacity and ciency of 65%, a minimum Recovery Ef? ciency of 60%, and Mercruiser I/O (gasoline) propulsion. The skimmers are ex- a minimum Recovery Rate of 6.5 gpm using ASTM Stan- tensively tested by the Navy and exceed all performance and dard F 631-93 encountering a 1mm slick thickness of with technical requirements. A total of 31 of these units were

Diesel Fuel Marine (DFM) and JP-5 at towed speeds of 0.5 delivered from 1995 to 1997, signi? cantly improving the – 2.5 knots, in calm and protected water surface conditions. Navy’s spill response capability in the US and overseas.

• Generation II Skimmers, 1997: Kvichak upgrades the

Always Evolving, Constantly innovating vessel’s propulsion to Volvo I/O (diesel fuel) engine pro-

The only constant in Kvichak’s history of producing pulsion, improving safety, reliability and performance. A reliable skimmers has, interestingly enough, been change. total 26 units were delivered from 1997 to 2005.

May 2015

MN 44

43

43

45

45