How to Choose Propulsion Systems for Patrol Craft

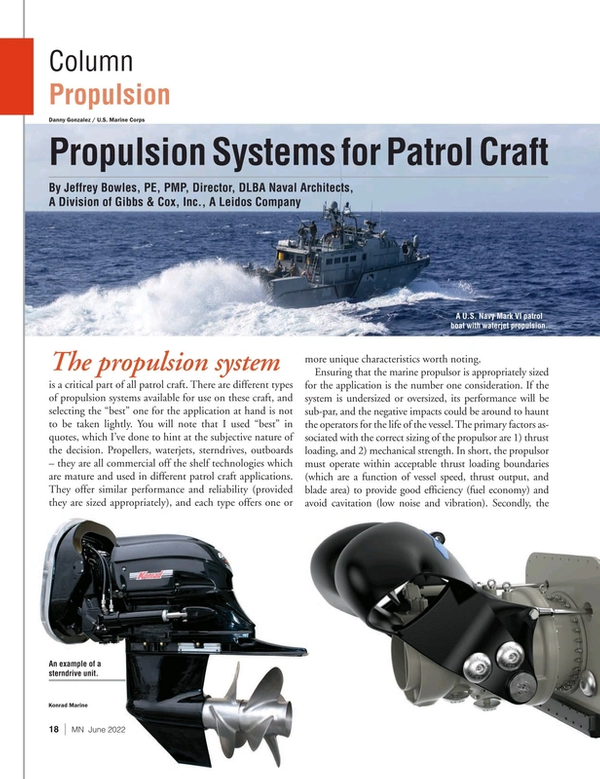

The propulsion system is a critical part of all patrol craft. There are different types of propulsion systems available for use on these craft, and selecting the “best” one for the application at hand is not to be taken lightly. You will note that I used “best” in quotes, which I’ve done to hint at the subjective nature of the decision. Propellers, waterjets, sterndrives, outboards – they are all commercial off the shelf technologies which are mature and used in different patrol craft applications. They offer similar performance and reliability (provided they are sized appropriately), and each type offers one or more unique characteristics worth noting.

Ensuring that the marine propulsor is appropriately sized for the application is the number one consideration. If the system is undersized or oversized, its performance will be sub-par, and the negative impacts could be around to haunt the operators for the life of the vessel. The primary factors associated with the correct sizing of the propulsor are 1) thrust loading, and 2) mechanical strength. In short, the propulsor must operate within acceptable thrust loading boundaries (which are a function of vessel speed, thrust output, and blade area) to provide good efficiency (fuel economy) and avoid cavitation (low noise and vibration). Secondly, the device must have enough metal to withstand the torque, thrust, and other forces resulting from operation for reliable operation. We all know that equipment failures occurring during engagements are highly frowned upon.

When selecting propulsor size, the mechanical strength part is easy—the vendors have data tables on the equipment specifying the appropriate duty rating and recommended power limits. All equipment manufacturers and their distributors will help you pick the right size components and supply you with a good product, but you must decide what product you want first. This is the subjective part, which comes first in the selection process.

An example of a sterndrive unit. (Image: Konrad Marine)

An example of a sterndrive unit. (Image: Konrad Marine)

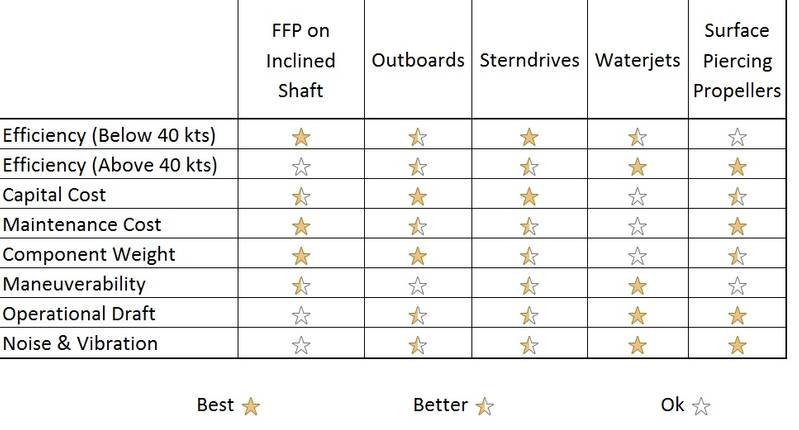

What type of propulsion system do you want? The needs of the vessel mission will ultimately drive the selection, within reasonable bounds, of course. Are swimmer safety or shallow draft key elements? If so, then a waterjet is a pretty good choice. Is maximum speed and light weight paramount? Then a surface piercing propeller might get the nod. Is the platform big and heavy enough that four 18” diameter propellers will cavitate prior to hump speed? Then outboards aren’t an option. The table below lists the key performance characteristics I consider every time I work with a customer to select a propulsion system type. For each propulsor type, there is a qualitative ranking against those performance characteristics. Use this to guide your selection. If you are unsure about the decision based on your gut feel and this table, you probably should call your naval architect.

The thrust loading part of the sizing equation is not necessarily challenging, but it does require inputs from the designer and end user that are critical to the process. The physical size of the propulsors must be selected to suit the maximum amount of resistance that the vessel will experience and is expected to perform in. Allowances for vessel weight growth, payload growth, overload operational conditions, marine growth, added resistance due to waves, head winds, and towing requirements (sometimes at high speeds) must be included in the resistance estimates used for selecting the right size propulsor.

You’ll find that once you pack up the allowances in a tactical fashion, and begin working through the equipment distributor, you need a big set of wheels. Maybe not huge, but bigger than you originally thought. This is always the case for high-speed vessels, which must carry heavy payloads in demanding conditions. Instead of defaulting to the traditional path of going bigger, look at the current trend of sticking with smaller units—but installing them in a higher quantity. The fast crew vessel boat industry is the trend setter here in my opinion, and we are all aware that the recreational boat industry is following this track as transoms are covered with outboards these days. While it may seem odd to consider deviating from twin screws on a normal boat, the demands on patrol boats are now anything but normal.

A U.S. Coast Guard 25-foot Response Boat-Small underway powered by dual 225hp outboards (Photo: Rich Condit / U.S. Coast Guard)

A U.S. Coast Guard 25-foot Response Boat-Small underway powered by dual 225hp outboards (Photo: Rich Condit / U.S. Coast Guard)

The two primary benefits of increasing above two drivelines are:

Graceful degradation – if a boat with two engines loses one shaftline, odds are it will not accelerate through hump. If a boat with more than three engines loses one shaftline, odds are it will be able to accelerate through hump and attain planing speeds.

Increased availability – With multiple shaftlines the smaller equipment is more affordable. It becomes possible (although maybe not palatable) to maintain spares on hand, enabling an approach of maintenance by replacement.

IMO III and EPA 4 requirements are driving commercial operators to adopt this approach to keep propulsion engines under 600 BKW (800 BHP) of rated output. In the case studies that I’ve examined in the past, I’ve found that the equipment costs are similar between the two different scenarios (this is without considering the cost of the exhaust after treatment now required on the larger engines). The point is there are lots of people exploring the benefits on increased quantity instead of size—so should you.

An example of surface drives (Photo: Twin Disc)

An example of surface drives (Photo: Twin Disc)

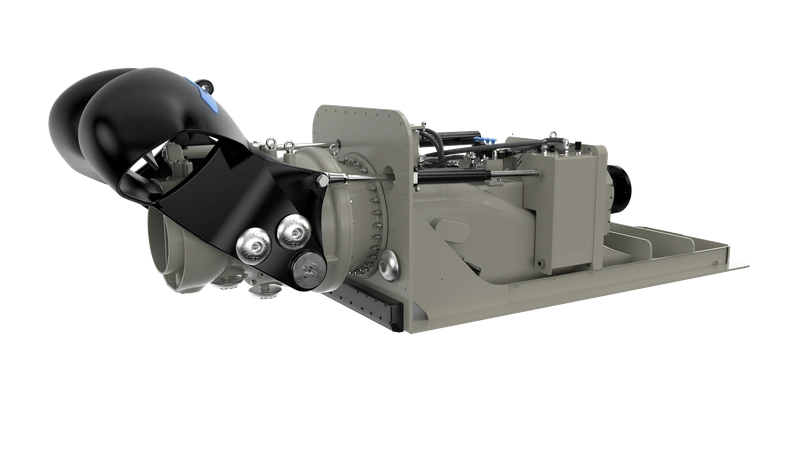

An example of a waterjet (Image: Marine Jet Power)

An example of a waterjet (Image: Marine Jet Power)

Read How to Choose Propulsion Systems for Patrol Craft in Pdf, Flash or Html5 edition of June 2022 Marine News

Other stories from June 2022 issue

Content

- Interview: Johan Inden, Volvo Penta page: 12

- How to Choose Propulsion Systems for Patrol Craft page: 18

- Updates, Developments and Advances in Combat and Patrol Craft page: 22

- Maritime Communications: Easier, Faster, Cheaper page: 28

- SAFE Boats: Keeping ’Em Coming page: 34

- IMTRA: Growth from Within page: 36

- Where Failure is Not an Option page: 38