The Evolution of Modern-day Shipbuilding

In the grand tradition of American innovation, we've long been masters of the maritime domain, building advanced ships for our Navy, the preeminent force in the world. But times have changed, and seas are more treacherous than they used to be. With this, there are ample opportunities for innovators to launch a new era of shipbuilding for the 21st Century.

When people think of American shipbuilding, they often look to U.S. shipyards’ historic shipbuilding in World War II. Production lines pushed out almost 3,000 Liberty Ships crewed by talented Merchant Mariners. These vessels were integral to carrying the guns and butter needed to win the War. Since those glory days, processes have evolved and improved given new technology, information and lessons learned from the past.

Building a new ship – of any kind – is no small feat. A new government or large-scale commercial vessel requires millions of dollars, thousands of people, and hundreds of custom parts – not to mention the right shipyard, a strong industrial base of suppliers and, ideally, both speed and patience.

Today, the vessel construction management (VCM) model presents a common-sense, efficient approach to building new non-combatant ships for the Navy, Coast Guard and other U.S. institutions such as our country's maritime training academies. VCM is designed to utilize best practices in commercial shipbuilding for the benefit of new government shipbuilding programs. Together, private sector innovators and public sector leaders can maintain and build on this country’s strong maritime history.

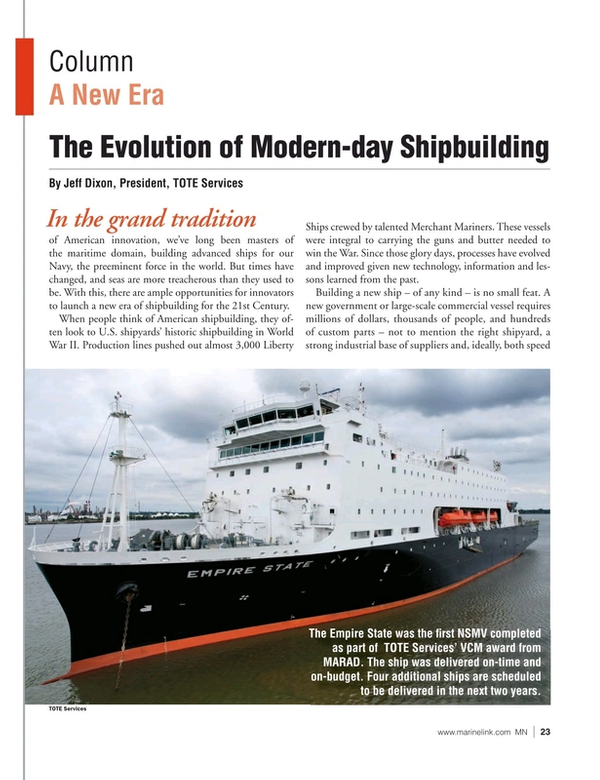

The Empire State was the first NSMV completed as part of TOTE Services' VCM award from MARAD. The ship was delivered on-time and on-budget. Four additional ships are scheduled to be delivered in the next two years. (Photo: TOTE Services)

The Empire State was the first NSMV completed as part of TOTE Services' VCM award from MARAD. The ship was delivered on-time and on-budget. Four additional ships are scheduled to be delivered in the next two years. (Photo: TOTE Services)

Conceptually, the VCM model is similar to hiring a general contractor to build a home. The vessel construction manager identifies the right experts and team to meet the design specifications for the customer – in this case the US government.

With VCM, the government identifies vessel requirements and empowers the vessel construction manager to execute the contract based on best commercial practices. This arrangement – as seen with the National Security Multi-Mission Vessel (NSMV) construction program currently in progress at TOTE Services – has many benefits including:

- Providing the government with one point of contact, the VCM;

- Allowing all involved parties the ability to focus on their expertise, in particular the shipbuilder;

- Identifying and empowering a VCM to drive accountability, timeline and budget goals;

- Expands the number of available shipyards that can compete for government shipbuilding;

In the case of TOTE Services’ NSMV VCM contract, this model has delivered the first vessel on time and on budget (within 1%), with the remaining four vessels currently scheduled for delivery over the next two years.

At times, past government vessel construction projects have surpassed budget estimates by upwards of 30% while also experiencing significant delays in construction as highlighted in a May 2024 report by the Government Accountability Office (GAO).

While not all government-run vessel construction projects face these challenges, utilizing the VCM model provides a strategic opportunity for partnerships that leverage existing knowledge and expertise throughout the shipbuilding process.

Recently, the Secretary of the Navy, Carlos Del Toro, noted during a speech at Harvard’s Kennedy School that the shipbuilding and commercial infrastructure is critical to U.S. national security and also it is critical to “invest in commercial shipyards here in the U.S., modernizing and expanding our shipbuilding industrial capacity and creating a healthier, more competitive shipbuilding workforce.”

In addition to the Navy, the U.S. Coast Guard is focused on vessel construction with the recapitalization of certain ship classes.

Vessel construction management can expand shipbuilding efforts in the United States that, in return, bolster the broader domestic maritime sector. In addition, it results in benefits to the taxpayer, resulting in projects that are on budget and on time.

In its recent report, the GAO also noted the importance of leveraging commercial expertise and processes when designing and building ships for the Navy. The report highlights that:

- Commercial ship buyers and builders have a shorter and more predictable time for ship construction;

- Leading practices are able to successfully manage the shipbuilding process which includes meeting the customer’s needs;

- Commercial focus on finalizing the ship design ensures clarity on schedule, cost and performance.

As noted above, TOTE Services’ contract with the Maritime Administration (MARAD) for the five NSMVs highlights both the opportunity and success for VCM to support U.S. shipbuilding. As part of this process, TOTE Services managed the NSMV design and building through critical partnerships with naval architects and Philly Shipyard. The NSMV contract included a firm fixed-price contract, fully designed vessel and little room for change orders. Further, the commercial experience was leveraged to manage risk and potential delays across the multi-year program including throughout the COVID-19 pandemic and resulting supply chain challenges.

It's time for the U.S. to fully embrace VCM and leverage the expertise and benefits of this model. These partnerships and collaboration are good for all aspects of the maritime sector, national security and the taxpayer.

(Photo: Philly Shipyard)

(Photo: Philly Shipyard)

Read The Evolution of Modern-day Shipbuilding in Pdf, Flash or Html5 edition of June 2024 Marine News

Other stories from June 2024 issue

Content

- Insights: Richard Schwarz, SAFE Boats International page: 10

- Government Shipbuilding Could Soon Enter American Living Rooms page: 20

- The Evolution of Modern-day Shipbuilding page: 23

- Congress Raises the National Security Alarm on Shipbuilding page: 26

- Autonomous Vessels: Already Working, but Still Under Close Review page: 28

- Inside Project Perfect Storm page: 34

- Deflating Mythology: New Book Unpacks the History Behind the Jones Act page: 38