Page 28: of Marine Technology Magazine (April 2006)

The Offshore Technology Edition

Read this page in Pdf, Flash or Html5 edition of April 2006 Marine Technology Magazine

28 MTR April 2006 tage of providing field storage, which enables them to be utilized independent of pipeline infrastructure. They are also less weight sensitive than other types of floating pro- duction systems and the extensive deck area of a large tanker provides flexibility in process plant layout.

Another advantage is the ability to utilize surplus or aging tanker hulls for conversion to an FPSO vessel, a solution which can be relatively inexpensive compared to building a new hull. The disadvantage is that the subsea tiebacks associated with FPSOs generally bring higher well main- tenance costs.

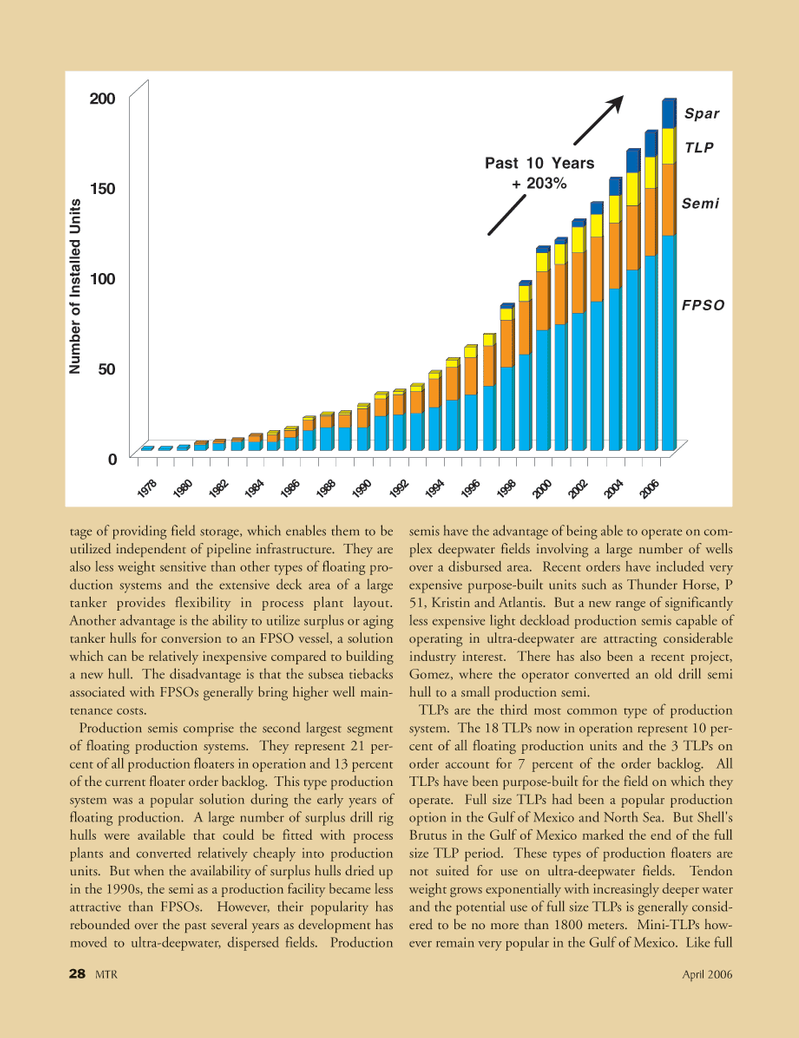

Production semis comprise the second largest segment of floating production systems. They represent 21 per- cent of all production floaters in operation and 13 percent of the current floater order backlog. This type production system was a popular solution during the early years of floating production. A large number of surplus drill rig hulls were available that could be fitted with process plants and converted relatively cheaply into production units. But when the availability of surplus hulls dried up in the 1990s, the semi as a production facility became less attractive than FPSOs. However, their popularity has rebounded over the past several years as development has moved to ultra-deepwater, dispersed fields. Production semis have the advantage of being able to operate on com- plex deepwater fields involving a large number of wells over a disbursed area. Recent orders have included very expensive purpose-built units such as Thunder Horse, P 51, Kristin and Atlantis. But a new range of significantly less expensive light deckload production semis capable of operating in ultra-deepwater are attracting considerable industry interest. There has also been a recent project,

Gomez, where the operator converted an old drill semi hull to a small production semi.

TLPs are the third most common type of production system. The 18 TLPs now in operation represent 10 per- cent of all floating production units and the 3 TLPs on order account for 7 percent of the order backlog. All

TLPs have been purpose-built for the field on which they operate. Full size TLPs had been a popular production option in the Gulf of Mexico and North Sea. But Shell's

Brutus in the Gulf of Mexico marked the end of the full size TLP period. These types of production floaters are not suited for use on ultra-deepwater fields. Tendon weight grows exponentially with increasingly deeper water and the potential use of full size TLPs is generally consid- ered to be no more than 1800 meters. Mini-TLPs how- ever remain very popular in the Gulf of Mexico. Like full

Past 10 Years + 203%

Number of Installed Units 1978 1980 1982 1984 1986 1988 1990 1992 1994 1996 1998 2000 2002 2004 2006 0 50 100 150 200

FPSO

Semi

TLP

Spar

MTR#3 (17-32).qxd 4/7/2006 11:32 AM Page 28

27

27

29

29