Page 14: of Marine Technology Magazine (September 2015)

Ocean Observation: Gliders, Buoys & Sub-Surface Networks

Read this page in Pdf, Flash or Html5 edition of September 2015 Marine Technology Magazine

People & Company News

Island can be measured. The radar and launched, operated and recovered with alerts it generates are part of the Ocean minimal setup.

Networks Canada Smart Ocean Systems that is strengthening Canada’s techno- New RV for University logical position providing ocean knowl- All American Marine, Inc. (AAM) has edge for sound decision making. Ocean entered into a contract with the Univer-

Networks Canada is funded by the Gov- sity of New Hampshire (UNH) for the ernment of Canada and includes a part- design and construction of a new alumi- nership with IBM Canada. num catamaran research vessel. AAM will build the 48 x 17 ft. catamaran cus- tom devised by Teknicraft Design, Ltd.

Teledyne RD Instruments

Supplies DVLs for LAUV of Auckland, New Zealand.

Teledyne RD Instruments supplied The new vessel, funded through a

Portugal-based underwater vehicle grant from the National Oceanic and (Image: ASL Environmental Sciences) systems designer and manufacturer Atmospheric Administration (NOAA)

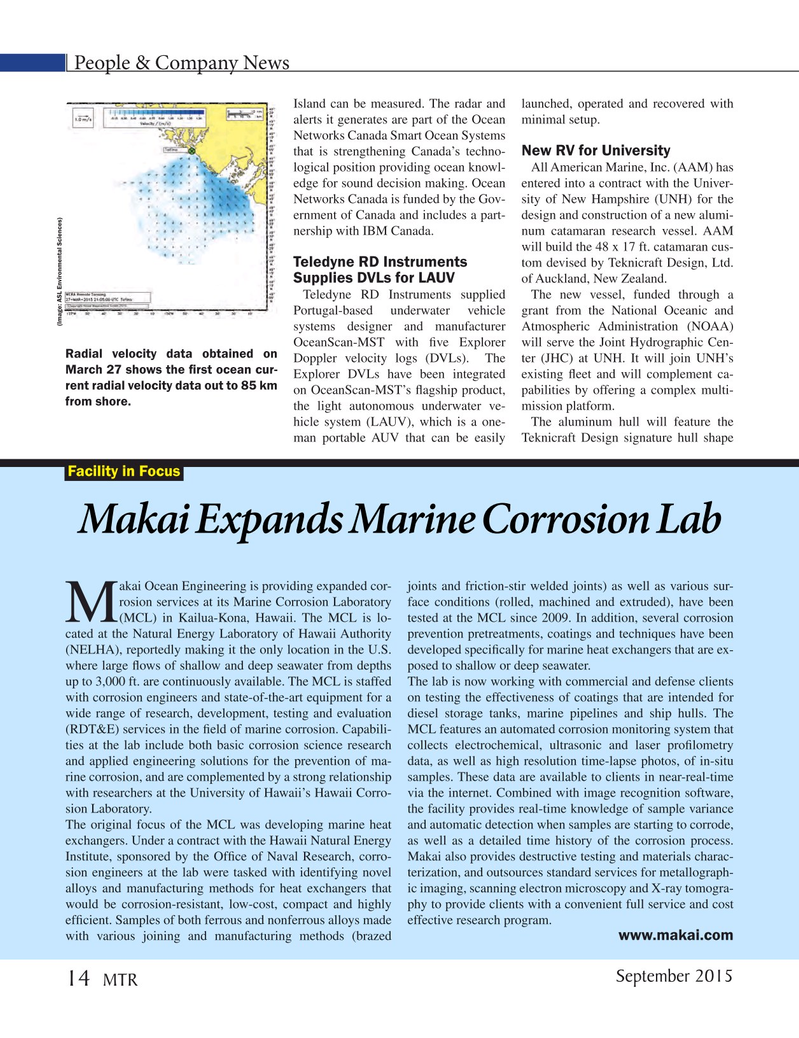

Radial velocity data obtained on OceanScan-MST with ? ve Explorer will serve the Joint Hydrographic Cen-

Doppler velocity logs (DVLs). The ter (JHC) at UNH. It will join UNH’s

March 27 shows the ? rst ocean cur-

Explorer DVLs have been integrated existing ? eet and will complement ca- rent radial velocity data out to 85 km on OceanScan-MST’s ? agship product, pabilities by offering a complex multi- from shore.

the light autonomous underwater ve- mission platform.

hicle system (LAUV), which is a one- The aluminum hull will feature the man portable AUV that can be easily Teknicraft Design signature hull shape

Facility in Focus

Makai Expands Marine Corrosion Lab akai Ocean Engineering is providing expanded cor- joints and friction-stir welded joints) as well as various sur- rosion services at its Marine Corrosion Laboratory face conditions (rolled, machined and extruded), have been

M(MCL) in Kailua-Kona, Hawaii. The MCL is lo- tested at the MCL since 2009. In addition, several corrosion cated at the Natural Energy Laboratory of Hawaii Authority prevention pretreatments, coatings and techniques have been (NELHA), reportedly making it the only location in the U.S. developed speci? cally for marine heat exchangers that are ex- where large ? ows of shallow and deep seawater from depths posed to shallow or deep seawater.

up to 3,000 ft. are continuously available. The MCL is staffed The lab is now working with commercial and defense clients with corrosion engineers and state-of-the-art equipment for a on testing the effectiveness of coatings that are intended for wide range of research, development, testing and evaluation diesel storage tanks, marine pipelines and ship hulls. The (RDT&E) services in the ? eld of marine corrosion. Capabili- MCL features an automated corrosion monitoring system that ties at the lab include both basic corrosion science research collects electrochemical, ultrasonic and laser pro? lometry and applied engineering solutions for the prevention of ma- data, as well as high resolution time-lapse photos, of in-situ rine corrosion, and are complemented by a strong relationship samples. These data are available to clients in near-real-time with researchers at the University of Hawaii’s Hawaii Corro- via the internet. Combined with image recognition software, sion Laboratory. the facility provides real-time knowledge of sample variance

The original focus of the MCL was developing marine heat and automatic detection when samples are starting to corrode, exchangers. Under a contract with the Hawaii Natural Energy as well as a detailed time history of the corrosion process.

Institute, sponsored by the Of? ce of Naval Research, corro- Makai also provides destructive testing and materials charac- sion engineers at the lab were tasked with identifying novel terization, and outsources standard services for metallograph- alloys and manufacturing methods for heat exchangers that ic imaging, scanning electron microscopy and X-ray tomogra- would be corrosion-resistant, low-cost, compact and highly phy to provide clients with a convenient full service and cost ef? cient. Samples of both ferrous and nonferrous alloys made effective research program. www.makai.com with various joining and manufacturing methods (brazed

September 2015 14

MTR

MTR #7 (1-17).indd 14 MTR #7 (1-17).indd 14 9/1/2015 9:44:58 AM9/1/2015 9:44:58 AM

13

13

15

15