Page 14: of Marine Technology Magazine (March 2018)

Oceanographic Instrumentation: Measurement, Process & Analysis

Read this page in Pdf, Flash or Html5 edition of March 2018 Marine Technology Magazine

Cables concrete mattresses, rock trenching and articulated pipes. In 2014, FMGC has launched an R&D project in partner-

However, all existing conventional methods show some dis- ship with Innosea and Gem to answer the speci? c expecta- advantages at certain point, usually in terms of corrosion, tions of the Marine Renewable Energy industry. The aim of cost-ef? ciency, bending radius, design or fatigue of the elec- the project was to develop a full range of articulated cast iron trical conductors. shells that protect, ballast and stabilize subsea conducts (ca-

Aware of the criticality and the importance of this matter, bles, pipes, etc) and semiautomatic installation equipment.

marine renewable energy professionals welcome any new The primary goal of the protecting and ballasting shells is decision that can improve the current situation and deliver to signi? cantly reduce the cost of the electrical connection reliable submarine cable protection. for MRE solutions and through it, to reduce the cost of the kWh.

An Innovative Solution After several months, the IBOCS consortium designed,

A European leader in the manufacture of cast iron counter- manufactured and tested its ? rst shells in February 2015. 40 weights for a wide range of industries, the French foundry m of cast iron shells (réf : IBS-70-88) around a 69 mm in di-

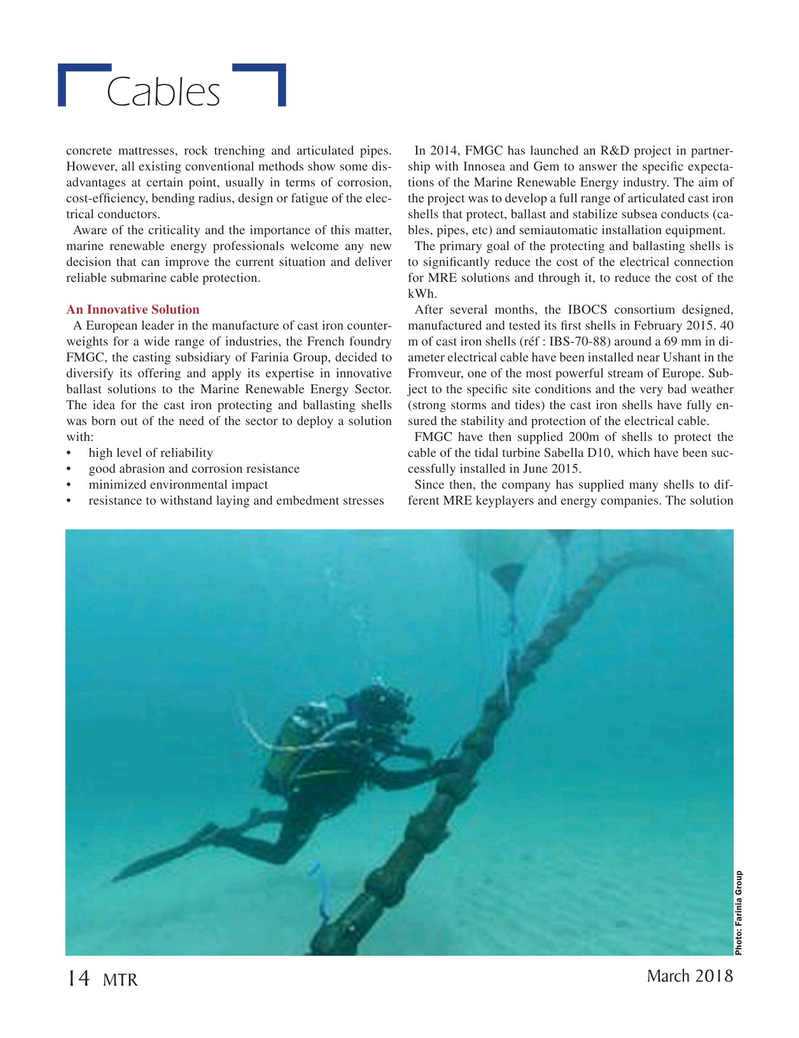

FMGC, the casting subsidiary of Farinia Group, decided to ameter electrical cable have been installed near Ushant in the diversify its offering and apply its expertise in innovative Fromveur, one of the most powerful stream of Europe. Sub- ballast solutions to the Marine Renewable Energy Sector. ject to the speci? c site conditions and the very bad weather

The idea for the cast iron protecting and ballasting shells (strong storms and tides) the cast iron shells have fully en- was born out of the need of the sector to deploy a solution sured the stability and protection of the electrical cable.

with: FMGC have then supplied 200m of shells to protect the • high level of reliability cable of the tidal turbine Sabella D10, which have been suc- • good abrasion and corrosion resistance cessfully installed in June 2015. • minimized environmental impact Since then, the company has supplied many shells to dif- • resistance to withstand laying and embedment stresses ferent MRE keyplayers and energy companies. The solution

Photo: Farinia Group 2018 March 14 MTR

MTR #2 (1-17).indd 14 MTR #2 (1-17).indd 14 2/20/2018 3:17:47 PM2/20/2018 3:17:47 PM

13

13

15

15