Page 12: of Marine Technology Magazine (June 2018)

Underwater Defense

Read this page in Pdf, Flash or Html5 edition of June 2018 Marine Technology Magazine

Trending in Renewable Energy

Photos: MacArtney

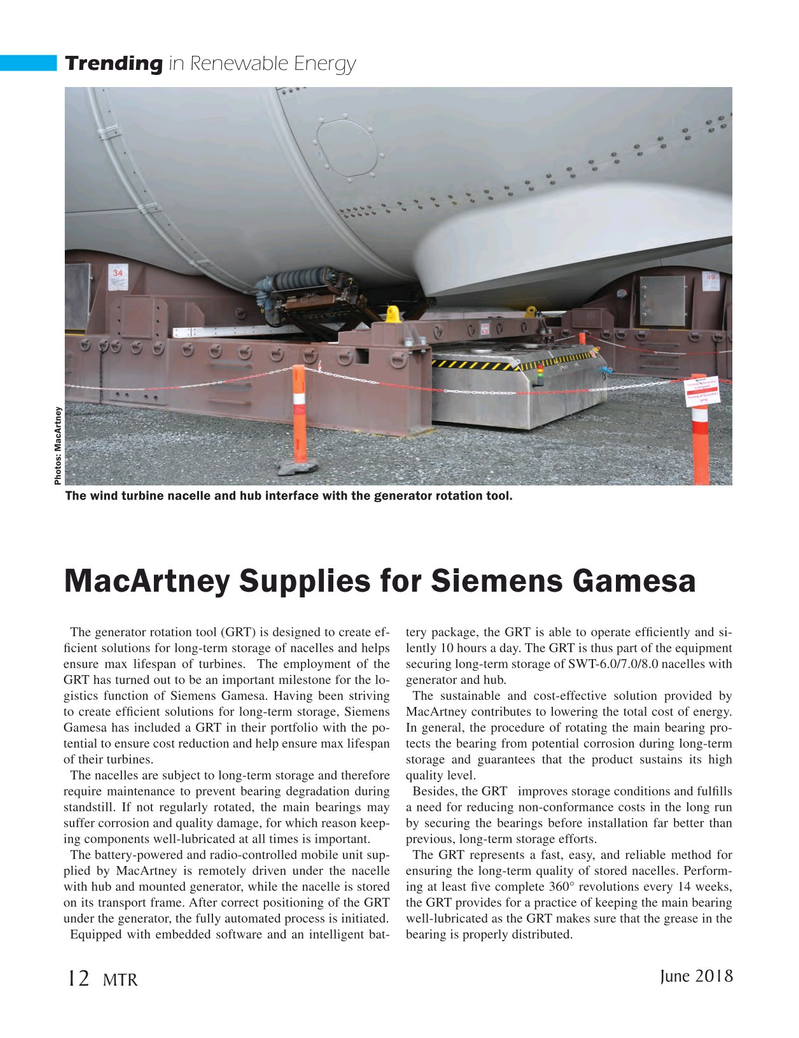

The wind turbine nacelle and hub interface with the generator rotation tool.

MacArtney Supplies for Siemens Gamesa

The generator rotation tool (GRT) is designed to create ef- tery package, the GRT is able to operate ef? ciently and si- ? cient solutions for long-term storage of nacelles and helps lently 10 hours a day. The GRT is thus part of the equipment ensure max lifespan of turbines. The employment of the securing long-term storage of SWT-6.0/7.0/8.0 nacelles with

GRT has turned out to be an important milestone for the lo- generator and hub.

gistics function of Siemens Gamesa. Having been striving The sustainable and cost-effective solution provided by to create ef? cient solutions for long-term storage, Siemens MacArtney contributes to lowering the total cost of energy.

Gamesa has included a GRT in their portfolio with the po- In general, the procedure of rotating the main bearing pro- tential to ensure cost reduction and help ensure max lifespan tects the bearing from potential corrosion during long-term of their turbines. storage and guarantees that the product sustains its high

The nacelles are subject to long-term storage and therefore quality level. require maintenance to prevent bearing degradation during Besides, the GRT improves storage conditions and ful? lls standstill. If not regularly rotated, the main bearings may a need for reducing non-conformance costs in the long run suffer corrosion and quality damage, for which reason keep- by securing the bearings before installation far better than ing components well-lubricated at all times is important. previous, long-term storage efforts.

The battery-powered and radio-controlled mobile unit sup- The GRT represents a fast, easy, and reliable method for plied by MacArtney is remotely driven under the nacelle ensuring the long-term quality of stored nacelles. Perform- with hub and mounted generator, while the nacelle is stored ing at least ? ve complete 360° revolutions every 14 weeks, on its transport frame. After correct positioning of the GRT the GRT provides for a practice of keeping the main bearing under the generator, the fully automated process is initiated. well-lubricated as the GRT makes sure that the grease in the

Equipped with embedded software and an intelligent bat- bearing is properly distributed.

2018 June 12 MTR

MTR #5 (1-17).indd 12 MTR #5 (1-17).indd 12 5/29/2018 10:45:49 AM5/29/2018 10:45:49 AM

11

11

13

13