Page 42: of Marine Technology Magazine (March 2023)

Read this page in Pdf, Flash or Html5 edition of March 2023 Marine Technology Magazine

LANDER LAB #7 SUBSEA HOUSINGS

With purge systems such as the Global Ocean Design Deck the plastic valve from exposure to any ocean pressure.

Purge Box (DPB-107), a vacuum leak test may be performed after the ? rst draw down to ½ atmosphere. The vacuum gauge One example of an open port purge port is found on Ed- connected to the housing interior should show a static partial geTech releases. This purge port is simply a smooth bore with vacuum. If there is a slow loss of the vacuum, there is a leak a small 1/16” diameter hole at the bottom that restricts air ? ow somewhere. It could be the vacuum test unit, but it may be the in and out of the housing. Before deployment a blanking plug housing itself. with dual seals plugs the open port, restrained by a non-me-

A purge system based on dynamically drying the air using tallic crow’s foot. An adapter ? tting connects the housing to a desiccants, such as the Global Ocean Design Deck Purge purge system, including the Global Ocean Design Deck Purge

Box, Figure 4, is inherently safe. Once the interior pressure is Box. A vacuum leak test can be performed to check the seals equalized with the exterior pressure, the ? ow stops. are working as they should. Because there is no check valve in the purge port of the EdgeTech release, the end user is left

PURGE PORTS with two choices for sealing.

Three purge port designs are currently in use: open port, self- The ? rst is to allow the interior pressure of the release to sealing, and occasionally a pressure relief valve (PRV). equalize with the room ambient pressure, then remove the

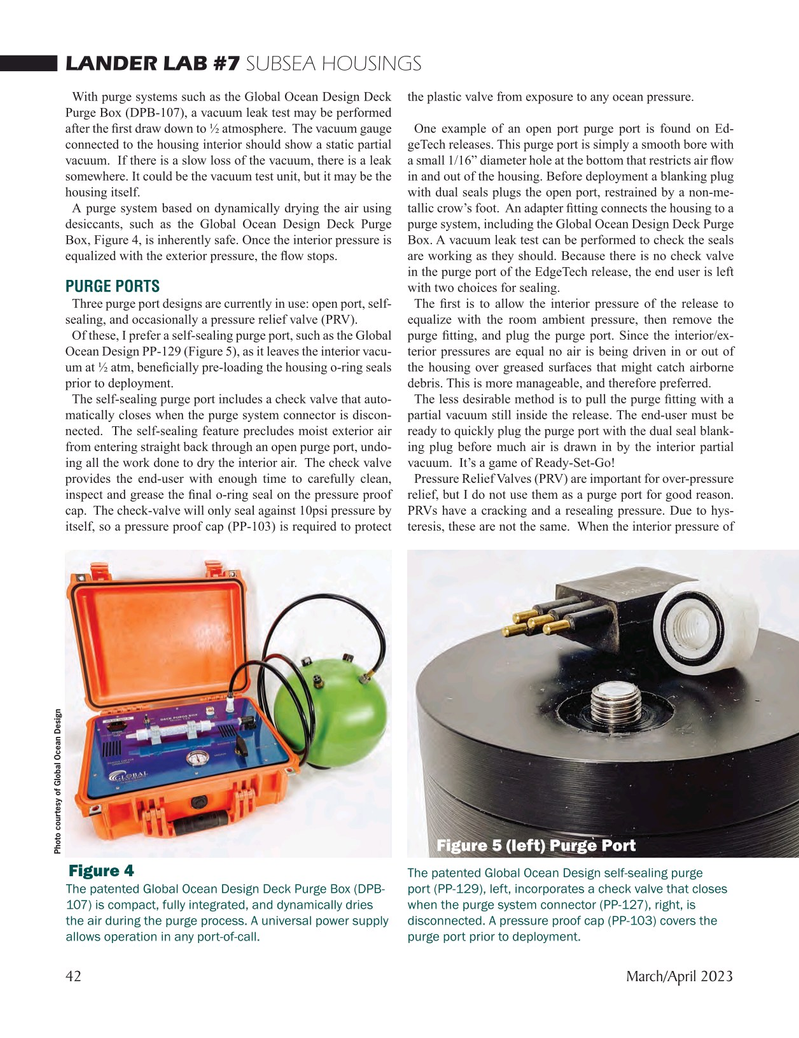

Of these, I prefer a self-sealing purge port, such as the Global purge ? tting, and plug the purge port. Since the interior/ex-

Ocean Design PP-129 (Figure 5), as it leaves the interior vacu- terior pressures are equal no air is being driven in or out of um at ½ atm, bene? cially pre-loading the housing o-ring seals the housing over greased surfaces that might catch airborne prior to deployment. debris. This is more manageable, and therefore preferred.

The self-sealing purge port includes a check valve that auto- The less desirable method is to pull the purge ? tting with a matically closes when the purge system connector is discon- partial vacuum still inside the release. The end-user must be nected. The self-sealing feature precludes moist exterior air ready to quickly plug the purge port with the dual seal blank- from entering straight back through an open purge port, undo- ing plug before much air is drawn in by the interior partial ing all the work done to dry the interior air. The check valve vacuum. It’s a game of Ready-Set-Go!

provides the end-user with enough time to carefully clean, Pressure Relief Valves (PRV) are important for over-pressure inspect and grease the ? nal o-ring seal on the pressure proof relief, but I do not use them as a purge port for good reason. cap. The check-valve will only seal against 10psi pressure by PRVs have a cracking and a resealing pressure. Due to hys- itself, so a pressure proof cap (PP-103) is required to protect teresis, these are not the same. When the interior pressure of

Figure 5 (left) Purge Port

Photo courtesy of Global Ocean Design

Figure 4

The patented Global Ocean Design self-sealing purge

The patented Global Ocean Design Deck Purge Box (DPB- port (PP-129), left, incorporates a check valve that closes 107) is compact, fully integrated, and dynamically dries when the purge system connector (PP-127), right, is the air during the purge process. A universal power supply disconnected. A pressure proof cap (PP-103) covers the allows operation in any port-of-call. purge port prior to deployment.

42 March/April 2023

MTR #3 (34-49).indd 42 3/19/2023 7:50:34 PM

41

41

43

43