Page 37: of Marine Technology Magazine (March 2024)

Read this page in Pdf, Flash or Html5 edition of March 2024 Marine Technology Magazine

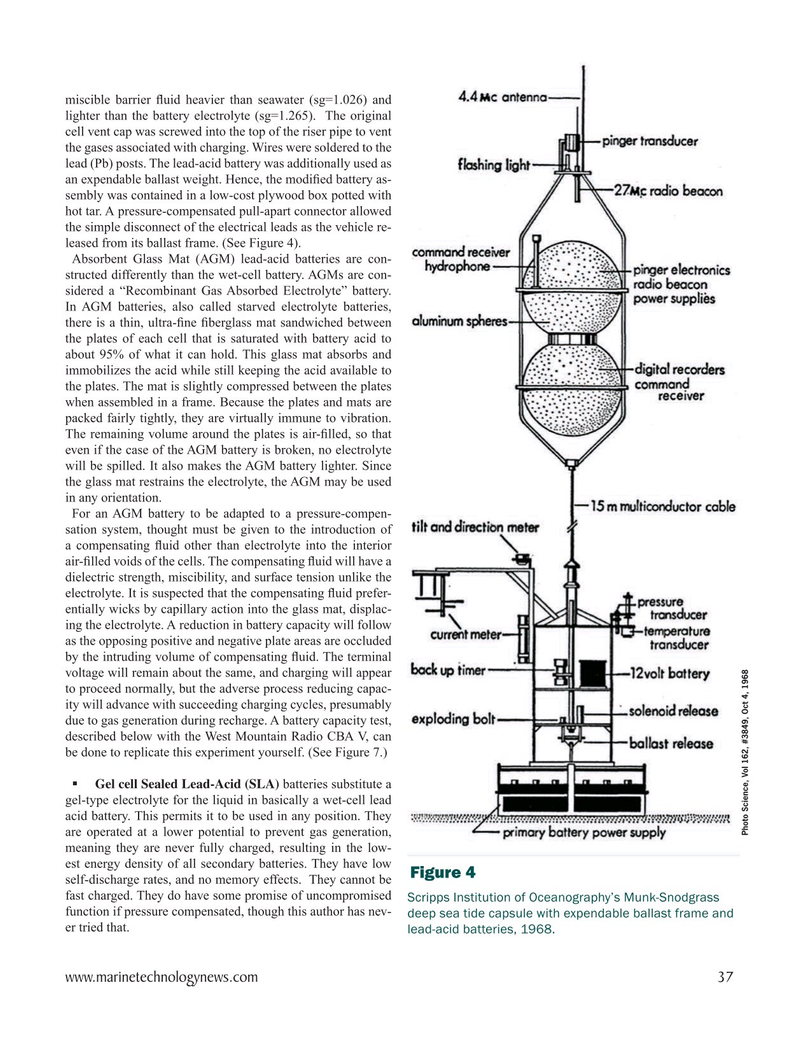

miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionally used as an expendable ballast weight. Hence, the modi? ed battery as- sembly was contained in a low-cost plywood box potted with hot tar. A pressure-compensated pull-apart connector allowed the simple disconnect of the electrical leads as the vehicle re- leased from its ballast frame. (See Figure 4).

Absorbent Glass Mat (AGM) lead-acid batteries are con- structed differently than the wet-cell battery. AGMs are con- sidered a “Recombinant Gas Absorbed Electrolyte” battery.

In AGM batteries, also called starved electrolyte batteries, there is a thin, ultra-? ne ? berglass mat sandwiched between the plates of each cell that is saturated with battery acid to about 95% of what it can hold. This glass mat absorbs and immobilizes the acid while still keeping the acid available to the plates. The mat is slightly compressed between the plates when assembled in a frame. Because the plates and mats are packed fairly tightly, they are virtually immune to vibration.

The remaining volume around the plates is air-? lled, so that even if the case of the AGM battery is broken, no electrolyte will be spilled. It also makes the AGM battery lighter. Since the glass mat restrains the electrolyte, the AGM may be used in any orientation.

For an AGM battery to be adapted to a pressure-compen- sation system, thought must be given to the introduction of a compensating ? uid other than electrolyte into the interior air-? lled voids of the cells. The compensating ? uid will have a dielectric strength, miscibility, and surface tension unlike the electrolyte. It is suspected that the compensating ? uid prefer- entially wicks by capillary action into the glass mat, displac- ing the electrolyte. A reduction in battery capacity will follow as the opposing positive and negative plate areas are occluded by the intruding volume of compensating ? uid. The terminal voltage will remain about the same, and charging will appear to proceed normally, but the adverse process reducing capac- ity will advance with succeeding charging cycles, presumably due to gas generation during recharge. A battery capacity test, described below with the West Mountain Radio CBA V, can be done to replicate this experiment yourself. (See Figure 7.) ? Gel cell Sealed Lead-Acid (SLA) batteries substitute a gel-type electrolyte for the liquid in basically a wet-cell lead acid battery. This permits it to be used in any position. They

Photo Science, Vol 162, #3849, Oct 4, 1968 are operated at a lower potential to prevent gas generation, meaning they are never fully charged, resulting in the low- est energy density of all secondary batteries. They have low

Figure 4 self-discharge rates, and no memory effects. They cannot be fast charged. They do have some promise of uncompromised Scripps Institution of Oceanography’s Munk-Snodgrass function if pressure compensated, though this author has nev- deep sea tide capsule with expendable ballast frame and er tried that.

lead-acid batteries, 1968.

www.marinetechnologynews.com 37

MTR #3 (34-47).indd 37 4/4/2024 10:53:09 AM

36

36

38

38