Page 42: of Maritime Reporter Magazine (January 1969)

Read this page in Pdf, Flash or Html5 edition of January 1969 Maritime Reporter Magazine

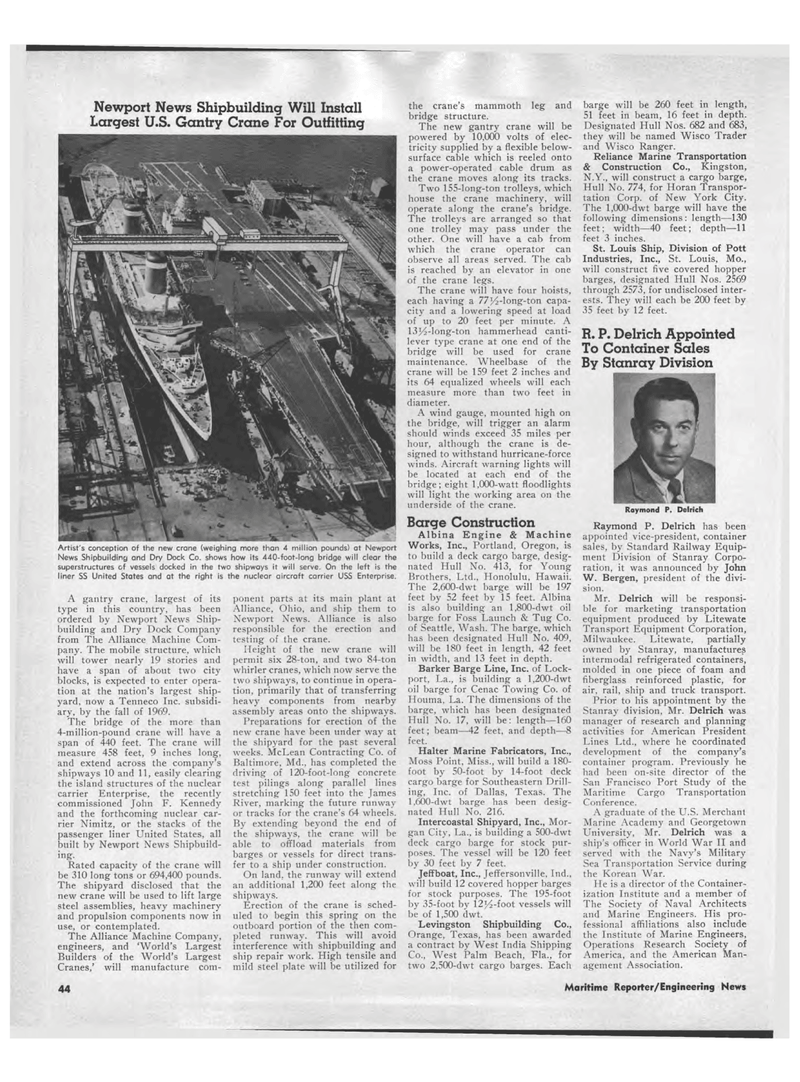

Newport News Shipbuilding Will Install Largest U.S. Gantry Crane For Outfitting Artist's conception of the new crane (weighing more than 4 million pounds) at Newport News Shipbuilding and Dry Dock Co. shows how its 440-foot-long bridge will clear the superstructures of vessels docked in the two shipways it will serve. On the left is the liner SS United States and at the right is the nuclear aircraft carrier USS Enterprise. A gantry crane, largest of its type in this country, has been ordered by Newport News Ship-building and Dry Dock Company from The Alliance Machine Com-pany. The mobile structure, which will tower nearly 19 stories and have a span of about two city blocks, is expected to enter opera-tion at the nation's largest ship-yard, now a Tenneco Inc. subsidi-ary, by the fall of 1969. The bridge of the more than 4-million-pound crane will have a span of 440 feet. The crane will measure 458 feet, 9 inches long, and extend across the company's shipways 10 and 11, easily clearing the island structures of the nuclear carrier Enterprise, the recently commissioned John F. Kennedy and the forthcoming nuclear car-rier Nimitz, or the stacks of the passenger liner United States, all built by Newport News Shipbuild-ing. Rated capacity of the crane will be 310 long tons or 694,400 pounds. The shipyard disclosed that the new crane will be used to lift large steel assemblies, heavy machinery and propulsion components now in use, or contemplated. The Alliance Machine Company, engineers, and 'World's Largest Builders of the World's Largest Cranes,' will manufacture com-ponent parts at its main plant at Alliance, Ohio, and ship them to Newport News. Alliance is also responsible for the erection and testing of the crane. Height of the new crane will permit six 28-ton, and two 84-ton whirler cranes, which now serve the two shipways, to continue in opera-tion, primarily that of transferring heavy components from nearby assembly areas onto the shipways. Preparations for erection of the new crane have been under way at the shipyard for the past several weeks. McLean Contracting Co. of Baltimore, Md., has completed the driving of 120-foot-long concrete test pilings along parallel lines stretching 150 feet into the Tames River, marking the future runway or tracks for the crane's 64 wheels. By extending beyond the end of the shipways, the crane will be able to offload materials from barges or vessels for direct trans-fer to a ship under construction. On land, the runway will extend an additional 1,200 feet along the shipways. Erection of the crane is sched-uled to begin this spring on the outboard portion of the then com-pleted runway. This will avoid interference with shipbuilding and ship repair work. High tensile and mild steel plate will be utilized for the crane's mammoth leg and bridge structure. The new gantry crane will be powered by 10,(XX) volts of elec-tricity supplied by a flexible below-surface cable which is reeled onto a power-operated cable drum as the crane moves along its tracks. Two 155-long-ton trolleys, which house the crane machinery, will operate along the crane's bridge. The trolleys are arranged so that one trolley may pass under the other. One will have a cab from which the crane operator can observe all areas served. The cab is reached by an elevator in one of the crane legs. The crane will have four hoists, each having a 77^-long-ton capa-city and a lowering speed at load of up to 20 feet per minute. A 13^2-long-ton hammerhead canti-lever type crane at one end of the bridge will be used for crane maintenance. Wheelbase of the crane will be 159 feet 2 inches and its 64 equalized wheels will each measure more than two feet in diameter. A wind gauge, mounted high on the bridge, will trigger an alarm should winds exceed 35 miles per hour, although the crane is de-signed to withstand hurricane-force winds. Aircraft warning lights will be located at each end of the bridge; eight 1,000-watt floodlights will light the working area on the underside of the crane. Barge Construction Albina Engine & Machine Works, Inc., Portland, Oregon, is to build a deck cargo barge, desig-nated Hull No. 413, for Young Brothers, Ltd., Honolulu, Hawaii. The 2,600-dwt barge will be 197 feet by 52 feet by 15 feet. Albina is also building an 1,800-dwt oil barge for Foss Launch & Tug Co. of Seattle, Wash. The barge, which has been designated Hull No. 409, will be 180 feet in length, 42 feet in width, and 13 feet in depth. Barker Barge Line, Inc. of Lock-port, La., is building a 1,200-dwt oil barge for Cenac Towing Co. of Houma, La. The dimensions of the barge, which has been designated Hull No. 17, will be: length?160 feet; beam?42 feet, and depth?8 feet. Halter Marine Fabricators, Inc., Moss Point, Miss., will build a 180-foot by 50-foot by 14-foot deck cargo barge for Southeastern Drill-ing, Inc. of Dallas, Texas. The 1,600-dwt barge has been desig-nated Hull No. 216. Intercoastal Shipyard, Inc., Mor-gan City, La., is building a 500-dwt deck cargo barge for stock pur-poses. The vessel will be 120 feet by 30 feet by 7 feet. Jeffboat, Inc., Jeffersonville, Ind., will build 12 covered hopper barges for stock purposes. The 195-foot by 35-foot by 12^-foot vessels will be of 1,500 dwt. Levingston Shipbuilding Co., Orange, Texas, has been awarded a contract by West India Shipping Co., West Palm Beach, Fla., for two 2,500-dwt cargo barges. Each barge will be 260 feet in length, 51 feet in beam, 16 feet in depth. Designated Hull Nos. 682 and 683, they will be named Wisco Trader and Wisco Ranger. Reliance Marine Transportation & Construction Co., Kingston, N.Y., will construct a cargo barge, Hull No. 774, for Horan Transpor-tation Corp. of New York City. The 1,000-dwt barge will have the following dimensions: length?130 feet; width?40 feet; depth?11 feet 3 inches. St. Louis Ship, Division of Pott Industries, Inc., St. Louis, Mo., will construct five covered hopper barges, designated Hull Nos. 2569 through 2573, for undisclosed inter-ests. They will each be 200 feet by 35 feet by 12 feet. R. P. Delrich Appointed To Container Sales By Stanray Division Raymond P. Delrich Raymond P. Delrich has been appointed vice-president, container sales, by Standard Railway Equip-ment Division of Stanray Corpo-ration, it was announced by John W. Bergen, president of the divi-sion. Mr. Delrich will be responsi-ble for marketing transportation equipment produced by Litewate Transport Equipment Corporation, Milwaukee. Litewate, partially owned by Stanray, manufactures intermodal refrigerated containers, molded in one piece of foam and fiberglass reinforced plastic, for air, rail, ship and truck transport. Prior to his appointment by the Stanray division, Mr. Delrich was manager of research and planning activities for American President Lines Ltd., where he coordinated development of the company's container program. Previously he had been on-site director of the San Francisco Port Study of the Maritime Cargo Transportation Conference. A graduate of the U.S. Merchant Marine Academy and Georgetown University, Mr. Delrich was a ship's officer in World War II and served with the Navy's Military Sea Transportation Service during the Korean War. He is a director of the Container-ization Institute and a member of The Society of Naval Architects and Marine Engineers. His pro-fessional affiliations also include the Institute of Marine Engineers, Operations Research Society of America, and the American Man-agement Association. 44 Maritime Reporter/Engineering News

41

41

43

43