Page 54: of Maritime Reporter Magazine (January 15, 1969)

Read this page in Pdf, Flash or Html5 edition of January 15, 1969 Maritime Reporter Magazine

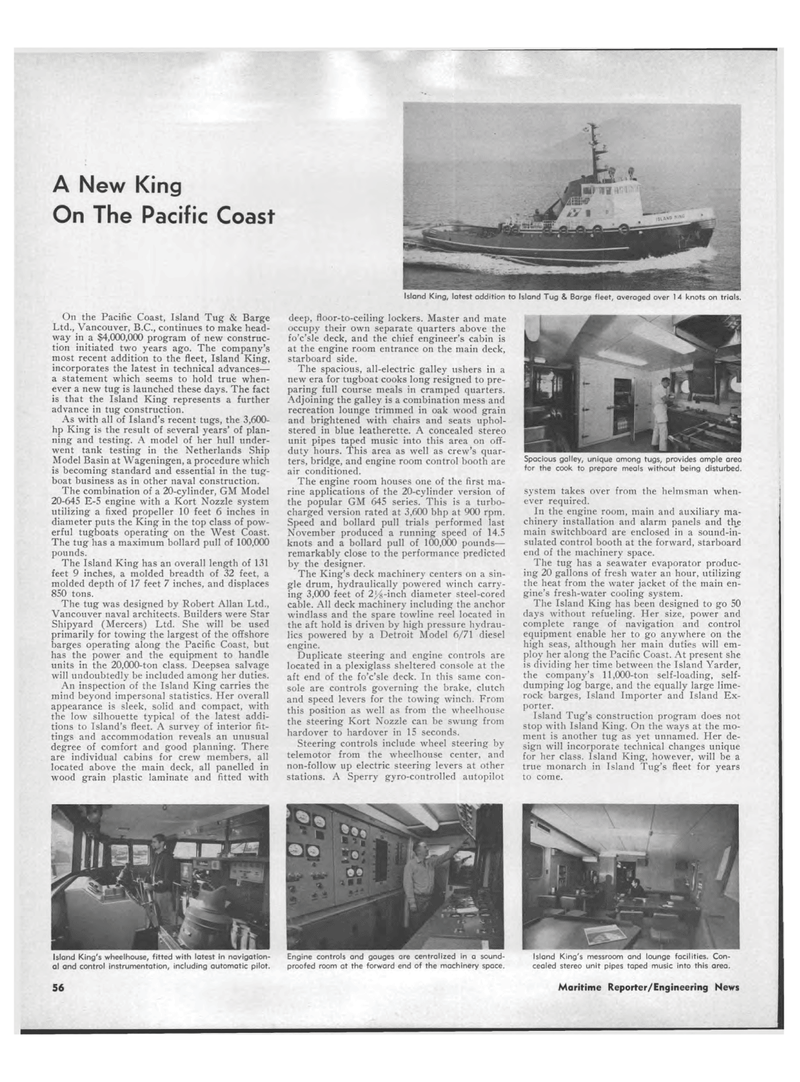

A New King On The Pacific Coast Island King, latest addition to Island Tug & Barge fleet, averaged over 1 4 knots on trials. On the Pacific Coast, Island Tug & Barge Ltd., Vancouver, B.C., continues to make head-way in a $4,000,000 program of new construc-tion initiated two years ago. The company's most recent addition to the fleet, Island King, incorporates the latest in technical advances? a statement which seems to hold true when-ever a new tug is launched these days. The fact is that the Island King represents a further advance in tug construction. As with all of Island's recent tugs, the 3,600-hp King is the result of several years' of plan-ning and testing. A model of her hull under-went tank testing in the Netherlands Ship Model Basin at Wageningen, a procedure which is becoming standard and essential in the tug-boat business as in other naval construction. The combination of a 20-cylinder, GM Model 20-645 E-5 engine with a Kort Nozzle system utilizing a fixed propeller 10 feet 6 inches in diameter puts the King in the top class of pow-erful tugboats operating on the West Coast. The tug has a maximum bollard pull of 100,000 pounds. The Island King has an overall length of 131 feet 9 inches, a molded breadth of 32 feet, a molded depth of 17 feet 7 inches, and displaces 850 tons. The tug was designed by Robert Allan Ltd., Vancouver naval architects. Builders were Star Shipyard (Mercers) Ltd. She will be used primarily for towing the largest of the offshore barges operating along the Pacific Coast, but has the power and the equipment to handle units in the 20,000-ton class. Deepsea salvage will undoubtedly be included among her duties. An inspection of the Island King carries the mind beyond impersonal statistics. Her overall appearance is sleek, solid and compact, with the low silhouette typical of the latest addi-tions to Island's fleet. A survey of interior fit-tings and accommodation reveals an unusual degree of comfort and good planning. There are individual cabins for crew members, all located above the main deck, all panelled in wood grain plastic laminate and fitted with deep, floor-to-ceiling lockers. Master and mate occupy their own separate quarters above the fo'c'sle deck, and the chief engineer's cabin is at the engine room entrance on the main deck, starboard side. The spacious, all-electric galley ushers in a new era for tugboat cooks long resigned to pre-paring full course meals in cramped quarters. Adjoining the galley is a combination mess and recreation lounge trimmed in oak wood grain and brightened with chairs and seats uphol-stered in blue leatherette. A concealed stereo unit pipes taped music into this area on off-duty hours. This area as well as crew's quar-ters, bridge, and engine room control booth are air conditioned. The engine room houses one of the first ma-rine applications of the 20-cylinder version of the popular GM 645 series. This is a turbo-charged version rated at 3,600 bhp at 900 rpm. Speed and bollard pull trials performed last November produced a running speed of 14.5 knots and a bollard pull of 100,000 pounds? remarkably close to the performance predicted by the designer. The King's deck machinery centers on a sin-gle drum, hydraulically powered winch carry-ing 3,000 feet of 2^-inch diameter steel-cored cable. All deck machinery including the anchor windlass and the spare towline reel located in the aft hold is driven by high pressure hydrau-lics powered by a Detroit Model 6/71 diesel engine. Duplicate steering and engine controls are located in a plexiglass sheltered console at the aft end of the fo'c'sle deck. In this same con-sole are controls governing the brake, clutch and speed levers for the towing winch. From this position as well as from the wheelhouse the steering Kort Nozzle can be swung from hardover to hardover in 15 seconds. Steering controls include wheel steering by telemotor from the wheelhouse center, and non-follow up electric steering levers at other stations. A Sperry gyro-controlled autopilot Spacious galley, unique among tugs, provides ample area for the cook to prepare meals without being disturbed. system takes over from the helmsman when-ever required. In the engine room, main and auxiliary ma-chinery installation and alarm panels and the main switchboard are enclosed in a sound-in-sulated control booth at the forward, starboard end of the machinery space. The tug has a seawater evaporator produc-ing 20 gallons of fresh water an hour, utilizing the heat from the water jacket of the main en-gine's fresh-water cooling system. The Island King has been designed to go 50 days without refueling. Her size, power and complete range of navigation and control equipment enable her to go anywhere on the high seas, although her main duties will em-ploy her along the Pacific Coast. At present she is dividing her time between the Island Yarder, the company's 11,000-ton self-loading, self-dumping log barge, and the equally large lime-rock barges, Island Importer and Island Ex-porter. Island Tug's construction program does not stop with Island King. On the ways at the mo-ment is another tug as yet unnamed. Her de-sign will incorporate technical changes unique for her class. Island King, however, will be a true monarch in Island Tug's fleet for years to come. Island King's wheelhouse, fitted with latest in navigation-al and control instrumentation, including automatic pilot. Engine controls and gauges are centralized in a sound-proofed room at the forward end of the machinery space. Island King's messroom and lounge facilities. Con-cealed stereo unit pipes taped music into this area. 56 Maritime Reporter/Engineering News

53

53

55

55