Page 52: of Maritime Reporter Magazine (February 15, 1969)

Read this page in Pdf, Flash or Html5 edition of February 15, 1969 Maritime Reporter Magazine

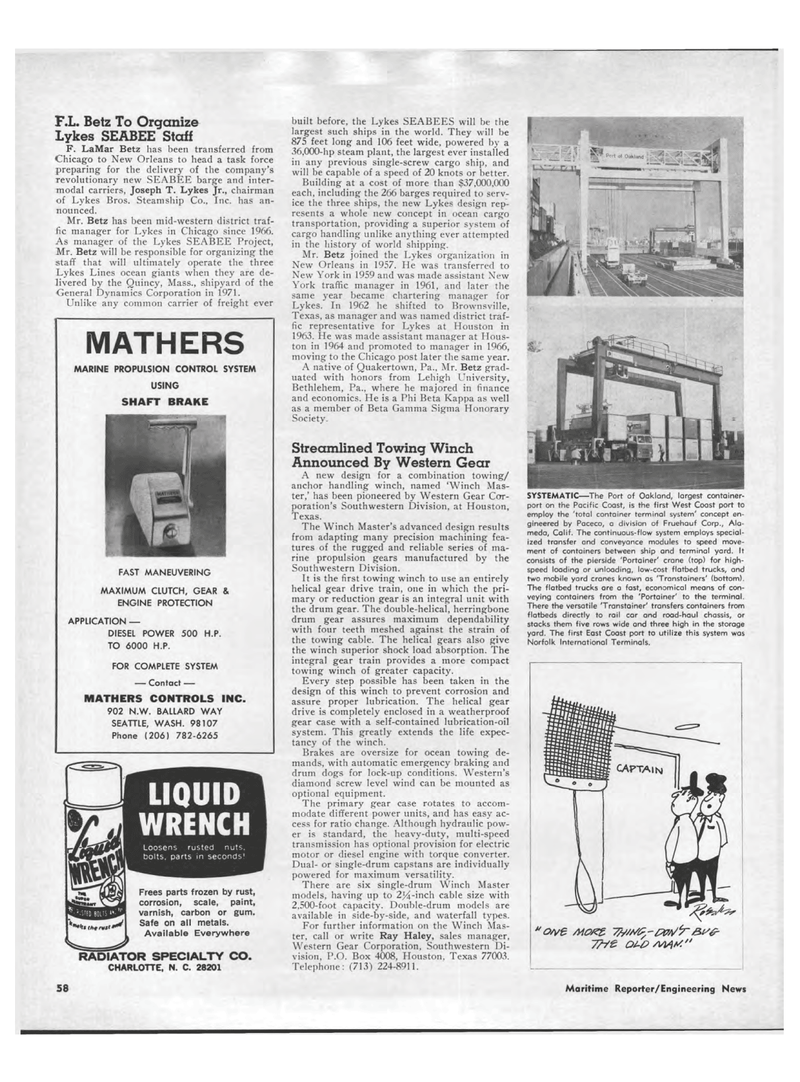

F.L. Betz To Organize Lykes SEABEE Staff F. LaMar Betz has been transferred from Chicago to New Orleans to head a task force preparing for the delivery of the company's revolutionary new SEABEE barge and inter-modal carriers, Joseph T. Lykes Jr., chairman of Lykes Bros. Steamship Co., Inc. has an-nounced. Mr. Betz has been mid-western district traf-fic manager for Lykes in Chicago since 1966. As manager of the Lykes SEABEE Project, Mr. Betz will be responsible for organizing the staff that will ultimately operate the three Lykes Lines ocean giants when they are de-livered by the Quincy, Mass., shipyard of the General Dynamics Corporation in 1971. Unlike any common carrier of freight ever MATHERS MARINE PROPULSION CONTROL SYSTEM USING SHAFT BRAKE 1; ~3P »> 11 J^K PM w^L J a.--'-VHH FAST MANEUVERING MAXIMUM CLUTCH, GEAR & ENGINE PROTECTION APPLICATION ? DIESEL POWER 500 H.P. TO 6000 H.P. FOR COMPLETE SYSTEM ? Contact ? MATHERS CONTROLS INC. 902 N.W. BALLARD WAY SEATTLE, WASH. 98107 Phone (206) 782-6265 LIQUID 1 WRENCH Loosens rusted nuts, bolts, parts in seconds! I Frees parts frozen by rust, corrosion, scale, paint, varnish, carbon or gum. Safe on all metals. Available Everywhere RADIATOR SPECIALTY CO. CHARLOTTE. N. C. 28201 built before, the Lykes SEABEES will be the largest such ships in the world. They will be 875 feet long and 106 feet wide, powered by a 36,000-hp steam plant, the largest ever installed in any previous single-screw cargo ship, and will be capable of a speed of 20 knots or better. Building at a cost of more than $37,000,000 each, including the 266 barges required to serv-ice the three ships, the new Lykes design rep-resents a whole new concept in ocean cargo transportation, providing a superior system of cargo handling unlike anything ever attempted in the history of world shipping. Mr. Betz joined the Lykes organization in New Orleans in 1957. He was transferred to New York in 1959 and was made assistant New York traffic manager in 1961, and later the same year became chartering manager for Lykes. In 1962 he shifted to Brownsville, Texas, as manager and was named district traf-fic representative for Lykes at Houston in 1963. He was made assistant manager at Hous-ton in 1964 and promoted to manager in 1966, moving to the Chicago post later the same year. A native of Quakertown, Pa., Mr. Betz grad-uated with honors from Lehigh University, Bethlehem, Pa., where he majored in finance and economics. He is a Phi Beta Kappa as well as a member of Beta Gamma Sigma Honorary Society. Streamlined Towing Winch Announced By Western Gear A new design for a combination towing/ anchor handling winch, named 'Winch Mas-ter,' has been pioneered by Western Gear Cor-poration's Southwestern Division, at Houston, Texas. The Winch Master's advanced design results from adapting many precision machining fea-tures of the rugged and reliable series of ma-rine propulsion gears manufactured by the Southwestern Division. It is the first towing winch to use an entirely helical gear drive train, one in which the pri-mary or reduction gear is an integral unit with the drum gear. The double-helical, herringbone drum gear assures maximum dependability with four teeth meshed against the strain of the towing cable. The helical gears also give the winch superior shock load absorption. The integral gear train provides a more compact towing winch of greater capacity. Every step possible has been taken in the design of this winch to prevent corrosion and assure proper lubrication. The helical gear drive is completely enclosed in a weatherproof gear case with a self-contained lubrication-oil system. This greatly extends the life expec-tancy of the winch. Brakes are oversize for ocean towing de-mands, with automatic emergency braking and drum dogs for lock-up conditions. Western's diamond screw level wind can be mounted as optional equipment. The primary gear case rotates to accom-modate different power units, and has easy ac-cess for ratio change. Although hydraulic pow-er is standard, the heavy-duty, multi-speed transmission has optional provision for electric motor or diesel engine with torque converter. Dual- or single-drum capstans are individually powered for maximum versatility. There are six single-drum Winch Master models, having up to 2^4-inch cable size with 2.500-foot capacity. Double-drum models are available in side-by-side, and waterfall types. For further information on the Winch Mas-ter, call or write Ray Haley, sales manager, Western Gear Corporation, Southwestern Di-vision, P.O. Box 4008, Houston. Texas 77003. Telephone: (713) 224-8911. SYSTEMATIC?The Port of Oakland, largest container-port on the Pacific Coast, is the first West Coast port to employ the 'total container terminal system' concept en-gineered by Paceco, a division of Fruehauf Corp., Ala-meda, Calif. The continuous-flow system employs special-ized transfer and conveyance modules to speed move-ment of containers between ship and terminal yard. It consists of the pierside 'Portainer' crane (top) for high-speed loading or unloading, low-cost flatbed trucks, and two mobile yard cranes known as 'Transtainers' (bottom). The flatbed trucks are a fast, economical means of con-veying containers from the 'Portainer' to the terminal. There the versatile 'Transtainer' transfers containers from flatbeds directly to rail car and road-haul chassis, or stacks them five rows wide and three high in the storage yard. The first East Coast port to utilize this system was Norfolk International Terminals. " OA/e MO/Z3 -7?ie /wt" P«l ot Oakland 58 Maritime Reporter/Engineering News

51

51

53

53