Page 4: of Maritime Reporter Magazine (February 15, 1969)

Read this page in Pdf, Flash or Html5 edition of February 15, 1969 Maritime Reporter Magazine

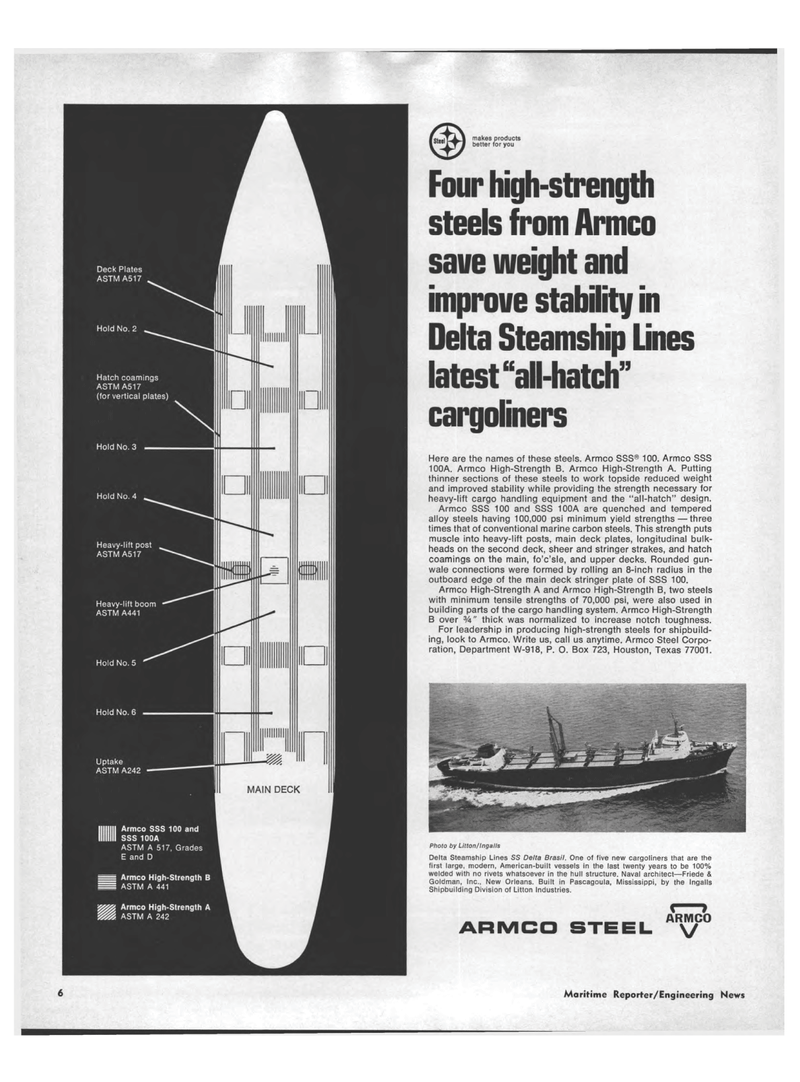

makes products better for you Four high-strength steels from Armco save weight and improve stability in Delta Steamship Lines latest "all-hatch" cargoliners Here are the names of these steels. Armco SSS® 100. Armco SSS 100A. Armco High-Strength B. Armco High-Strength A. Putting thinner sections of these steels to work topside reduced weight and improved stability while providing the strength necessary for heavy-lift cargo handling equipment and the "all-hatch" design. Armco SSS 100 and SSS 100A are quenched and tempered alloy steels having 100,000 psi minimum yield strengths ? three times that of conventional marine carbon steels. This strength puts muscle into heavy-lift posts, main deck plates, longitudinal bulk-heads on the second deck, sheer and stringer strakes, and hatch coamings on the main, fo'c'sle, and upper decks. Rounded gun-wale connections were formed by rolling an 8-inch radius in the outboard edge of the main deck stringer plate of SSS 100. Armco High-Strength A and Armco High-Strength B, two steels with minimum tensile strengths of 70,000 psi, were also used in building parts of the cargo handling system. Armco High-Strength B over 3/4" thick was normalized to increase notch toughness. For leadership in producing high-strength steels for shipbuild-ing, look to Armco. Write us, call us anytime. Armco Steel Corpo-ration, Department W-918, P. O. Box 723, Houston, Texas 77001. Photo by Litton/lngalls Delta Steamship Lines SS Delta Brasil. One of five new cargoliners that are the first large, modern, American-built vessels in the last twenty years to be 100% welded with no rivets whatsoever in the hull structure. Naval architect?Friede & Goldman, Inc., New Orleans. Built in Pascagoula, Mississippi, by the Ingalls Shipbuilding Division of Litton Industries. ARMCO STEEL ARMCO V 6 Maritime Reporter/Engineering News

3

3

5

5