Page 6: of Maritime Reporter Magazine (March 1969)

Read this page in Pdf, Flash or Html5 edition of March 1969 Maritime Reporter Magazine

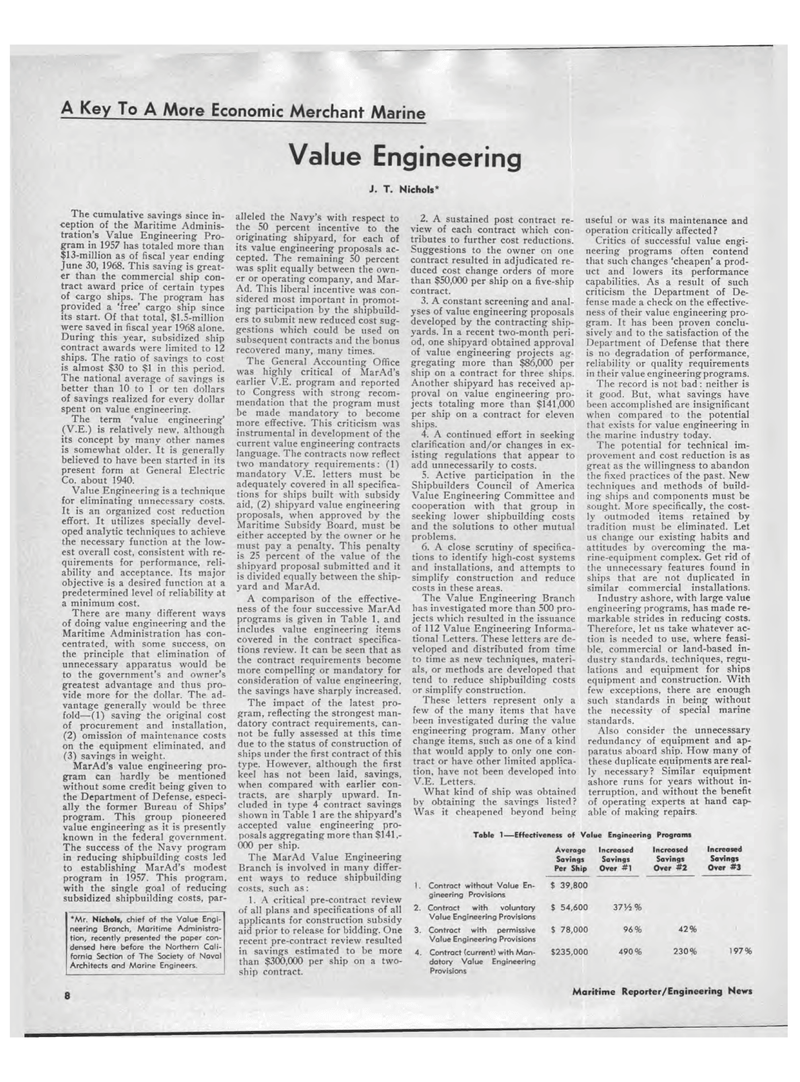

A Key To A More Economic Merchant Marine Value Engineering J. T. Nichols* The cumulative savings since in-ception of the Maritime Adminis-tration's Value Engineering Pro-gram in 1957 has totaled more than $13-million as of fiscal year ending June 30, 1968. This saving is great-er than the commercial ship con-tract award price of certain types of cargo ships. The program has provided a 'free' cargo ship since its start. Of that total, $1.5-million were saved in fiscal year 1968 alone. During this year, subsidized ship contract awards were limited to 12 ships. The ratio of savings to cost is almost $30 to $1 in this period. The national average of savings is better than 10 to 1 or ten dollars of savings realized for every dollar spent on value engineering. The term 'value engineering' (V.E.) is relatively new, although its concept by many other names is somewhat older. It is generally believed to have been started in its present form at General Electric Co. about 1940. Value Engineering is a technique for eliminating unnecessary costs. It is an organized cost reduction effort. It utilizes specially devel-oped analytic techniques to achieve the necessary function at the low-est overall cost, consistent with re-quirements for performance, reli-ability and acceptance. Its major objective is a desired function at a predetermined level of reliability at a minimum cost. There are many different ways of doing value engineering and the Maritime Administration has con-centrated, with some success, on the principle that elimination of unnecessary apparatus would be to the government's and owner's greatest advantage and thus pro-vide more for the dollar. The ad-vantage generally would be three fold?(1) saving the original cost of procurement and installation, (2) omission of maintenance costs on the equipment eliminated, and (3) savings in weight. MarAd's value engineering pro-gram can hardly be mentioned without some credit being given to the Department of Defense, especi-ally the former Bureau of Ships' program. This group pioneered value engineering as it is presently known in the federal government. The success of the Navy program in reducing shipbuilding costs led to establishing MarAd's modest program in 1957. This program, with the single goal of reducing subsidized shipbuilding costs, par-*Mr. Nichols, chief of the Value Engi-neering Branch, Maritime Administra-tion, recently presented the paper con-densed here before the Northern Cali-fornia Section of The Society of Naval Architects and Marine Engineers. alleled the Navy's with respect to the 50 percent incentive to the originating shipyard, for each of its value engineering proposals ac-cepted. The remaining 50 percent was split equally between the own-er or operating company, and Mar-Ad. This liberal incentive was con-sidered most important in promot-ing participation by the shipbuild-ers to submit new reduced cost sug-gestions which could be used on subsequent contracts and the bonus recovered many, many times. The General Accounting Office was highly critical of MarAd's earlier V.E. program and reported to Congress with strong recom-mendation that the program must be made mandatory to become more effective. This criticism was instrumental in development of the current value engineering contracts language. The contracts now reflect two mandatory requirements: (1) mandatory V.E. letters must be adequately covered in all specifica-tions for ships built with subsidy aid, (2) shipyard value engineering proposals, when approved by the Maritime Subsidy Board, must be either accepted by the owner or he must pay a penalty. This penalty is 25 percent of the value of the shipyard proposal submitted and it is divided equally between the ship-yard and MarAd. A comparison of the effective-ness of the four successive MarAd programs is given in Table 1, and includes value engineering items covered in the contract specifica-tions review. It can be seen that as the contract requirements become more compelling or mandatory for consideration of value engineering, the savings have sharply increased. The impact of the latest pro-gram, reflecting the strongest man-datory contract requirements, can-not be fully assessed at this time due to the status of construction of ships under the first contract of this type. However, although the first keel has not been laid, savings, when compared with earlier con-tracts, are sharply upward. In-cluded in type 4 contract savings shown in Table 1 are the shipyard's accepted value engineering pro-posals aggregating more than $141,-000 per ship. The MarAd Value Engineering Branch is involved in many differ-ent ways to reduce shipbuilding costs, such as: 1. A critical pre-contract review of all plans and specifications of all applicants for construction subsidy aid prior to release for bidding. One recent pre-contract review resulted in savings estimated to be more than $300,000 per ship on a two-ship contract. 2. A sustained post contract re-view of each contract which con-tributes to further cost reductions. Suggestions to the owner on one contract resulted in adjudicated re-duced cost change orders of more than $50,000 per ship on a five-ship contract. 3. A constant screening and anal-yses of value engineering proposals developed by the contracting ship-yards. In a recent two-month peri-od, one shipyard obtained approval of value engineering projects ag-gregating more than $86,000 per ship on a contract for three ships. Another shipyard has received ap-proval on value engineering pro-jects totaling more than $141,000 per ship on a contract for eleven ships. 4. A continued effort in seeking clarification and/or changes in ex-isting regulations that appear to add unnecessarily to costs. 5. Active participation in the Shipbuilders Council of America Value Engineering Committee and cooperation with that group in seeking lower shipbuilding costs and the solutions to other mutual problems. 6. A close scrutiny of specifica-tions to identify high-cost systems and installations, and attempts to simplify construction and reduce costs in these areas. The Value Engineering Branch has investigated more than 500 pro-jects which resulted in the issuance of 112 Value Engineering Informa-tional Letters. These letters are de-veloped and distributed from time to time as new techniques, materi-als, or methods are developed that tend to reduce shipbuilding costs or simplify construction. These letters represent only a few of the many items that have been investigated during the value engineering program. Many other change items, such as one of a kind that would apply to only one con-tract or have other limited applica-tion, have not been developed into V.E. Letters. What kind of ship was obtained by obtaining the savings listed? Was it cheapened beyond being useful or was its maintenance and operation critically affected? Critics of successful value engi-neering programs often contend that such changes 'cheapen' a prod-uct and lowers its performance capabilities. As a result of such criticism the Department of De-fense made a check on the effective-ness of their value engineering pro-gram. It has been proven conclu-sively and to the satisfaction of the Department of Defense that there is no degradation of performance, reliability or quality requirements in their value engineering programs. The record is not bad: neither is it good. But, what savings have been accomplished are insignificant when compared to the potential that exists for value engineering in the marine industry today. The potential for technical im-provement and cost reduction is as great as the willingness to abandon the fixed practices of the past. New techniques and methods of build-ing ships and components must be sought. More specifically, the cost-ly outmoded items retained by tradition must be eliminated. Let us change our existing habits and attitudes by overcoming the ma-rine-equipment complex. Get rid of the unnecessary features found in ships that are not duplicated in similar commercial installations. Industry ashore, with large value engineering programs, has made re-markable strides in reducing costs. Therefore, let us take whatever ac-tion is needed to use, where feasi-ble, commercial or land-based in-dustry standards, techniques, regu-lations and equipment for ships equipment and construction. With few exceptions, there are enough such standards in being without the necessity of special marine standards. Also consider the unnecessary redundancy of equipment and ap-paratus aboard ship. How many of these duplicate equipments are real-ly necessary? Similar equipment ashore runs for years without in-terruption. and without the benefit of operating experts at hand cap-able of making repairs. Table 1?Effectiveness of Value Engineering Programs 1. Contract without Value En-gineering Provisions 2. Contract with voluntary Value Engineering Provisions 3. Contract with permissive Value Engineering Provisions 4. Contract (current) with Man-datory Value Engineering Provisions Average Savings Per Ship $ 39,800 $ 54,600 $ 78,000 $235,000 Increased Savings Over #1 371/2' Increased Savings Over #2 96£ 490% Increased Savings Over #3 42% 230% 197% 8 Maritime Reporter/Engineering News

5

5

7

7