Page 28: of Maritime Reporter Magazine (March 15, 1969)

Read this page in Pdf, Flash or Html5 edition of March 15, 1969 Maritime Reporter Magazine

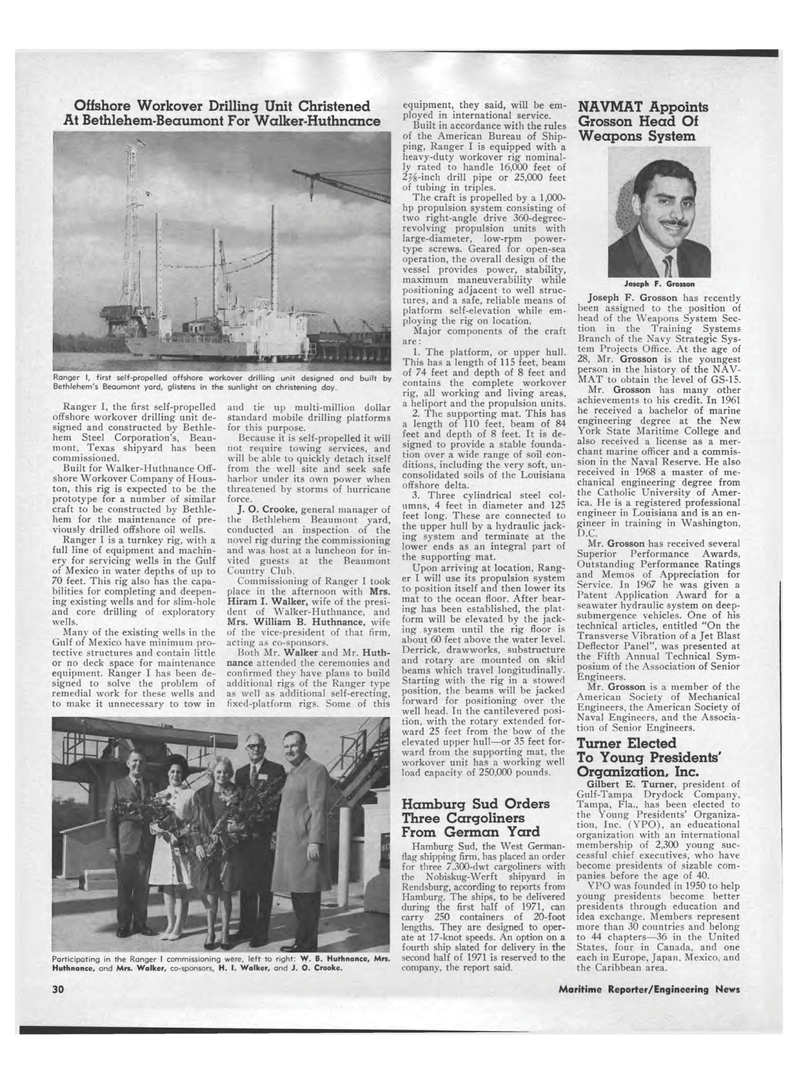

Offshore Workover Drilling Unit Christened At Bethlehem-Beaumont For Walker-Huthnance Ranger I, first self-propelled offshore workover drilling unit designed and built by Bethlehem's Beaumont yard, glistens in the sunlight on christening day. Ranger I, the first self-propelled offshore workover drilling unit de-signed and constructed by Bethle-hem Steel Corporation's, Beau-mont, Texas shipyard has been commissioned. Built for Walker-Huthnance Off-shore Workover Company of Hous-ton, this rig is expected to be the prototype for a number of similar craft to be constructed by Bethle-hem for the maintenance of pre-viously drilled offshore oil wells. Ranger I is a turnkey rig, with a full line of equipment and machin-ery for servicing wells in the Gulf of Mexico in water depths of up to 70 feet. This rig also has the capa-bilities for completing and deepen-ing existing wells and for slim-hole and core drilling of exploratory wells. Many of the existing wells in the Gulf of Mexico have minimum pro-tective structures and contain little or no deck space for maintenance equipment. Ranger I has been de-signed to solve the problem of remedial work for these wells and to make it unnecessary to tow in and tie up multi-million dollar standard mobile drilling platforms for this purpose. Because it is self-propelled it will not require towing services, and will be able to quickly detach itself from the well site and seek safe harbor under its own power when threatened by storms of hurricane force. J. O. Crooke, general manager of the Bethlehem Beaumont yard, conducted an inspection of the novel rig during the commissioning and was host at a luncheon for in-vited guests at the Beaumont Country Club. Commissioning of Ranger I took place in the afternoon with Mrs. Hiram I. Walker, wife of the presi-dent of Walker-Huthnance. and Mrs. William B. Huthnance, wife of the vice-president of that firm, acting as co-sponsors. Both Mr. Walker and Mr. Huth-nance attended the ceremonies and confirmed they have plans to build additional rigs of the Ranger type as well as additional self-erecting, fixed-platform rigs. Some of this equipment, they said, will be em-ployed in international service. Built in accordance with the rules of the American Bureau of Ship-ping, Ranger I is equipped with a heavy-duty workover rig nominal-ly rated to handle 16,000 feet of 2%-inch drill pipe or 25,000 feet of tubing in triples. The craft is propelled by a 1,000-hp propulsion system consisting of two right-angle drive 360-degree-revolving propulsion units with large-diameter, low-rpm power-type screws. Geared for open-sea operation, the overall design of the vessel provides power, stability, maximum maneuverability while positioning adjacent to well struc-tures, and a safe, reliable means of platform self-elevation while em-ploying the rig on location. Major components of the craft are: 1. The platform, or upper hull. This has a length of 115 feet, beam of 74 feet and depth of 8 feet and contains the complete workover rig, all working and living areas, a heliport and the propulsion units. 2. The supporting mat. This has a length of 110 feet, beam of 84 feet and depth of 8 feet. It is de-signed to provide a stable founda-tion over a wide range of soil con-ditions, including the very soft, un-consolidated soils of the Louisiana offshore delta. 3. Three cylindrical steel col-umns, 4 feet in diameter and 125 feet long. These are connected to the upper hull by a hydraulic jack-ing system and terminate at the lower ends as an integral part of the supporting mat. Upon arriving at location, Rang-er I will use its propulsion system to position itself and then lower its mat to the ocean floor. After bear-ing has been established, the plat-form will be elevated by the jack-ing system until the rig floor is about 60 feet above the water level. Derrick, drawworks, substructure and rotary are mounted on skid beams which travel longitudinally. Starting with the rig in a stowed position, the beams will be jacked forward for positioning over the well head. In the cantilevered posi-tion, with the rotary extended for-ward 25 feet from the bow of the elevated upper hull?or 35 feet for-ward from the supporting mat, the workover unit has a working well load capacity of 250,000 pounds. Hamburg Sud Orders Three Cargoliners From German Yard Hamburg Sud, the West German-flag shipping firm, has placed an order for three 7.300-dwt cargoliners with the Nobiskug-Werft shipyard in Rendsburg, according to reports from Hamburg. The ships, to be delivered during the first half of 1971, can carry 250 containers of 20-foot lengths. They are designed to oper-ate at 17-knot speeds. An option on a fourth ship slated for delivery in the second half of 1971 is reserved to the company, the report said. NAVMAT Appoints Grosson Head Of Weapons System Joseph F. Grosson Joseph F. Grosson has recently been assigned to the position of head of the Weapons System Sec-tion in the Training Systems Branch of the Navy Strategic Sys-tem Projects Office. At the age of 28, Mr. Grosson is the youngest person in the history of the NAV-MAT to obtain the level of GS-15. Mr. Grosson has many other achievements to his credit. In 1961 he received a bachelor of marine engineering degree at the New York State Maritime College and also received a license as a mer-chant marine officer and a commis-sion in the Naval Reserve. He also received in 1968 a master of me-chanical engineering degree from the Catholic University of Amer-ica. He is a registered professional engineer in Louisiana and is an en-gineer in training in Washington, D.C. Mr. Grosson has received several Superior Performance Awards, Outstanding Performance Ratings and Memos of Appreciation for Service. In 1967 he was given a Patent Application Award for a seawater hydraulic system on deep-submergence vehicles. One of his technical articles, entitled "On the Transverse Vibration of a Jet Blast Deflector Panel", was presented at the Fifth Annual Technical Sym-posium of the Association of Senior Engineers. Mr. Grosson is a member of the American Society of Mechanical Engineers, the American Society of Naval Engineers, and the Associa-tion of Senior Engineers. Turner Elected To Young Presidents' Organization, Inc. Gilbert E. Turner, president of Gulf-Tampa Drydock Company, Tampa, Fla., has been elected to the Young Presidents' Organiza-tion, Inc. (YPO), an educational organization with an international membership of 2,300 young suc-cessful chief executives, who have become presidents of sizable com-panies before the age of 40. YPO was founded in 1950 to help young presidents become better presidents through education and idea exchange. Members represent more than 30 countries and belong to 44 chapters?36 in the United States, four in Canada, and one each in Europe, Japan, Mexico, and the Caribbean area. Participating in the Ranger I commissioning were, left to right: W. B. Huthnance, Mrs. Huthnance, and Mrs. Walker, co-sponsors, H. I. Walker, and J. O. Crooke. 30 Maritime Reporter/Engineering News

27

27

29

29