Page 4: of Maritime Reporter Magazine (March 15, 1969)

Read this page in Pdf, Flash or Html5 edition of March 15, 1969 Maritime Reporter Magazine

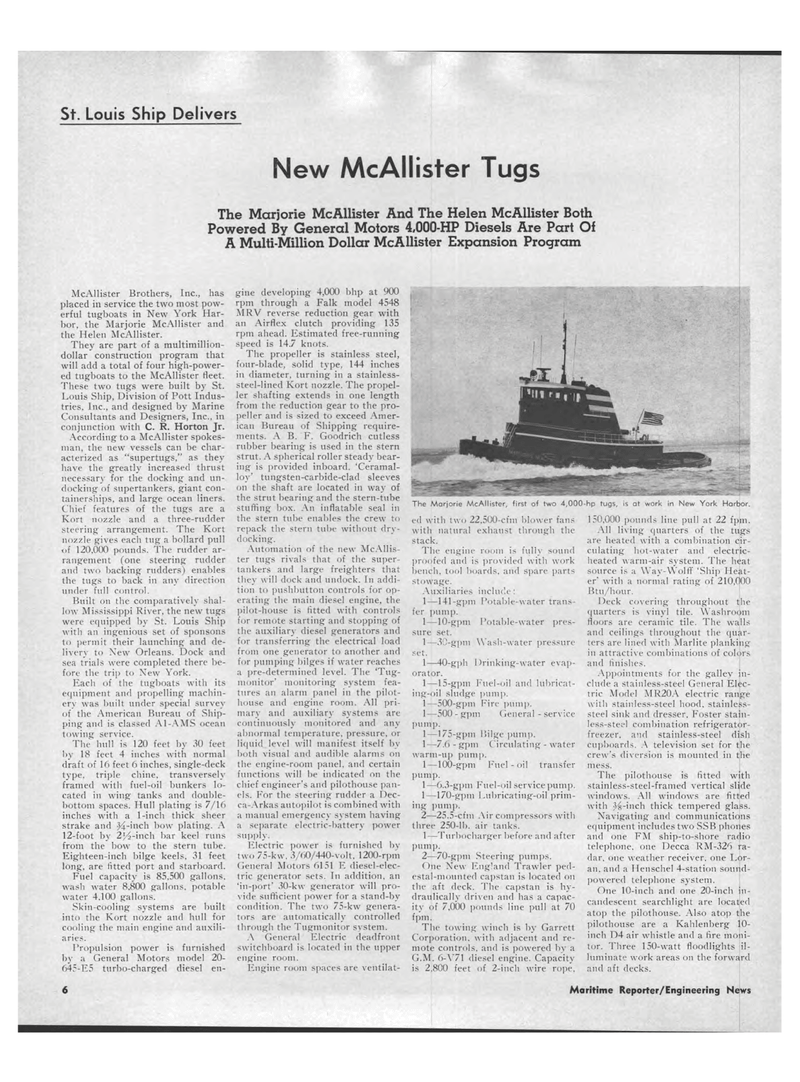

St. Louis Ship Delivers New McAllister Tugs The Marjorie McAllister And The Helen McAllister Both Powered By General Motors 4,000-HP Diesels Are Part Of A Multi-Million Dollar McAllister Expansion Program McAllister Brothers, Inc., has placed in service the two most pow-erful tugboats in New York Har-bor, the Marjorie McAllister and the Helen McAllister. They are part of a multimillion-dollar construction program that will add a total of four high-power-ed tugboats to the McAllister fleet. These two tugs were built by St. Louis Ship, Division of Pott Indus-tries. Inc., and designed by Marine Consultants and Designers, Inc., in conjunction with C. R. Horton Jr. According to a McAllister spokes-man, the new vessels can be char-acterized as "supertugs," as they have the greatly increased thrust necessary for the docking and uti-docking of supertankers, giant con-tainerships, and large ocean liners. Chief features of the tugs are a Kort nozzle and a three-rudder steering arrangement. The Kort nozzle gives each tug a bollard pull of 120.000 pounds. The rudder ar-rangement (one steering rudder and two backing rudders) enables the tugs to back in any direction under full control. Built on the comparatively shal-low Mississippi River, the new tugs were equipped by St. Louis Ship with an ingenious set of sponsons to permit their launching and de-livery to Xew Orleans. Dock and sea trials were completed there be-fore the trip to New York. Each of the tugboats with its equipment and propelling machin-ery was built under special survey of the American Bureau of Ship-ping and is classed Al-AMS ocean towing service. The hull is 120 feet by 30 feet by 18 feet 4 inches with normal draft of 16 feet 6 inches, single-deck type, triple chine, transversely framed with fuel-oil bunkers lo-cated in wing tanks and double-bottom spaces. Hull plating is 7/16 inches with a 1-inch thick sheer strake and ^4-inch bow plating. A 12-foot by 254-inch bar keel runs from the bow to the stern tube. Eighteen-inch bilge keels, 31 feet long, are fitted port and starboard. Fuel capacity is 85.500 gallons, wash water 8.800 gallons, potable water 4.100 gallons. Skin-cooling systems are built into the Kort nozzle and hull for cooling the main engine and auxili-aries. Propulsion power is furnished by a General Motors model 20-645-E5 turbo-charged diesel en-gine developing 4,000 bhp at 900 rpm through a Falk model 4548 MRV reverse reduction gear with an Airflex clutch providing 135 rpm ahead. Estimated free-running speed is 14.7 knots. The propeller is stainless steel, four-blade, solid type, 144 inches in diameter, turning in a stainless-steel-lined Kort nozzle. The propel-ler shafting extends in one length from the reduction gear to the pro-peller and is sized to exceed Amer-ican Bureau of Shipping require-ments. A B. F. Goodrich cutless rubber bearing is used in the stern strut. A spherical roller steady bear-ing is provided inboard. 'Ceramal-loy' tungsten-carbide-clad sleeves on the shaft are located in way of the strut bearing and the stern-tube stuffing box. An inflatable seal in the stern tube enables the crew to repack the stern tube without dry-docking. Automation of the new McAllis-ter tugs rivals that of the super-tankers and large freighters that they will dock and undock. In addi-tion to pushbutton controls for op-erating the main diesel engine, the pilot-house is fitted with controls for remote starting and stopping of the auxiliary diesel generators and for transferring the electrical load from one generator to another and for pumping bilges if water reaches a pre-determined level. The 'Tug-monitor' monitoring system fea-tures an alarm panel in the pilot-house and engine room. All pri-mary and auxiliary systems are continuously monitored and any abnormal temperature, pressure, or liquid level will manifest itself bv both visual and audible alarms on the engine-room panel, and certain functions will be indicated on the chief engineer's and pilothouse pan-els. For the steering rudder a Dec-ca-Arkas autopilot is combined with a manual emergency system having a separate electric-battery power supply. Electric power is furnished by two 75-kvv, 3/60/440-volt. 1200-rpm General Motors 6151 E diesel-elec-tric generator sets. In addition, an 'in-port' 30-kw generator will pro-vide sufficient power for a stand-by condition. The two 75-kw genera-tors are automatically controlled through the Tugmonitor system. A General Electric deadfront switchboard is located in the upper engine room. Engine room spaces are ventilat-The Marjorie McAllister, first of two 4,000-hp tugs, is at work in New York Harbor. ed with two 22.500-cfm blower fans with natural exhaust through the stack. The engine room is fully sound proofed and is provided with work bench, tool boards, and spare parts stowage. Auxiliaries include: 1?141-gpm Potable-water trans-fer pump. 1?10-gpm Potable-water pres-sure set. 1?30-gpm Wash-water pressure set. 1?40-gph Drinking-water evap-orator. 1?15-gpm Fuel-oil and lubricat-ing-oil sludge pump. 1?500-gpm Fire pump. 1?500 - gpm General - service pump. 1?175-gpm Bilge pump. 1?7.6 - gpm Circulating - water warm-up pump. 1?100-gpm Fuel - oil transfer pump. 1?6.3-gpm Fuel-oil service pump. 1?170-gpm Lubricating-oil prim-ing pump. 2?25.5-cfin Air compressors with three 250-lb. air tanks. 1?Turbocharger before and after pump. 2?70-gpni Steering pumps. One New England Trawler ped-estal-mounted capstan is located on the aft deck. The capstan is hy-draulically driven and has a capac-ity of 7,000 pounds line pull at 70 fpm. The towing winch is by Garrett Corporation, with adjacent and re-mote controls, and is powered by a G.M. 6-Y71 diesel engine. Capacity-is 2,800 feet of 2-inch wire rope, 150,000 pounds line pull at 22 fpm. All living quarters of the tugs are heated with a combination cir-culating hot-water and electric-heated warm-air system. The heat source is a Wav-Wolff 'Ship Heat-er' with a normal rating of 210,000 Btu/hour. Deck covering throughout the quarters is vinyl tile. Washroom floors are ceramic tile. The walls and ceilings throughout the quar-ters are lined with Marlite planking in attractive combinations of colors and finishes. Appointments for the galley in-clude a stainless-steel General Elec-tric Model MR20A electric range with stainless-steel hood, stainle$s-steel sink and dresser, Foster stain-less-steel combination refrigerator-freezer, and stainless-steel dish cupboards. A television set for the crew's diversion is mounted in the mess. The pilothouse is fitted with stainless-steel-framed vertical slide windows. All windows are fitted with -Hs-inch thick tempered glass. Navigating and communications equipment includes two SSB phones and one FM ship-to-shore radio telephone, one Decca RM-326 ra-dar, one weather receiver, one Lor-an. and a Henschel 4-station sound-powered telephone system. One 10-inch and one 20-inch in-candescent searchlight are located atop the pilothouse. Also atop the pilothouse are a Kahlenberg 10-inch D4 air whistle and a fire moni-tor. Three 150-watt floodlights il-luminate work areas on the forward and aft decks. 6 Maritime Reporter/Engineering News

3

3

5

5