Page 60: of Maritime Reporter Magazine (March 15, 1969)

Read this page in Pdf, Flash or Html5 edition of March 15, 1969 Maritime Reporter Magazine

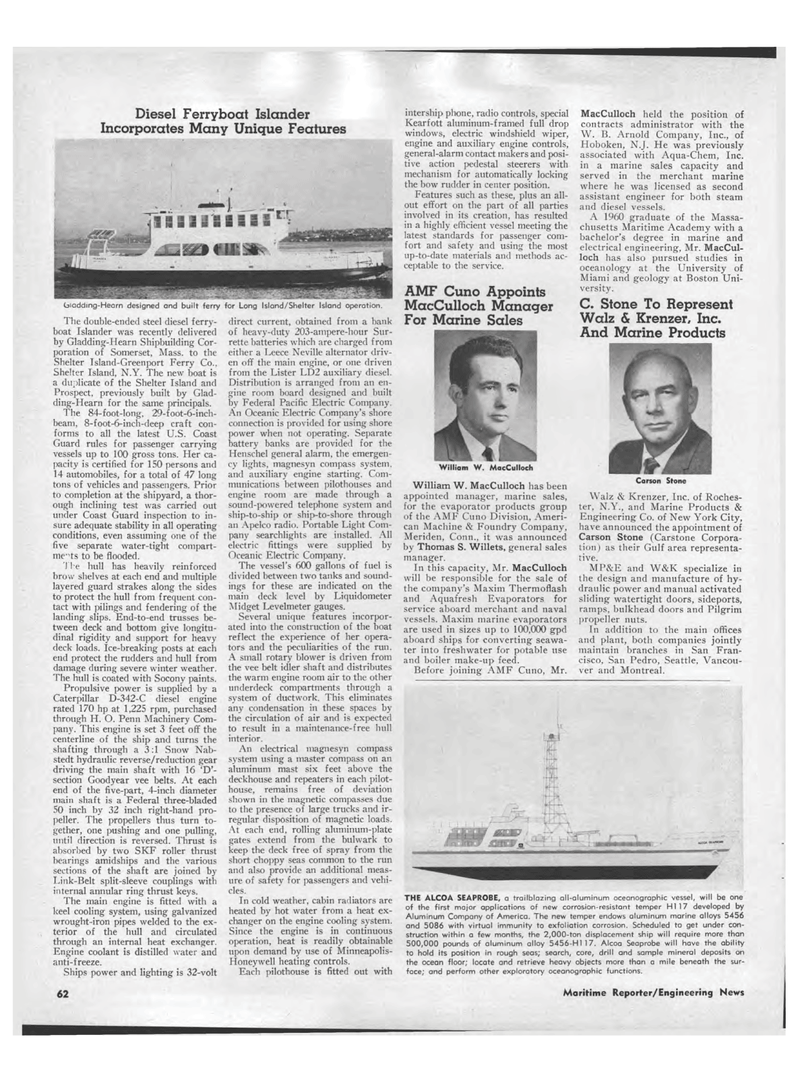

Diesel Ferryboat Islander Incorporates Many Unique Features biadding-Hearn designed and built ferry for Long Island/Shelter Island operation. The double-ended steel diesel ferry-boat Islander was recently delivered by Gladding-Hearn Shipbuilding Cor-poration of Somerset, Mass. to the Shelter Island-Greenport Ferry Co., Shelter Island, N.Y. The new boat is a duplicate of the Shelter Island and Prospect, previously built by Glad-ding-Hearn for the same principals. The 84-foot-long, 29-foot-6-inch-beam, 8-foot-6-inch-deep craft con-forms to all the latest U.S. Coast Guard rules for passenger carrying vessels up to 100 gross tons. Her ca-pacity is certified for 150 persons and 14 automobiles, for a total of 47 long tons of vehicles and passengers. Prior to completion at the shipyard, a thor-ough inclining test was carried out under Coast Guard inspection to in-sure adequate stability in all operating conditions, even assuming one of the five separate water-tight compart-ments to be flooded. I he hull has heavily reinforced brow shelves at each end and multiple layered guard strakes along the sides to protect the hull from frequent con-tact with pilings and fendering of the landing slips. End-to-end trusses be-tween deck and bottom give longitu-dinal rigidity and support for heavy deck loads. Ice-breaking posts at each end protect the rudders and hull from damage during severe winter weather. The hull is coated with Socony paints. Propulsive power is supplied by a Caterpillar D-342-C diesel engine rated 170 hp at 1,225 rpm, purchased through H. O. Penn Machinery Com-pany. This engine is set 3 feet off the centerline of the ship and turns the shafting through a 3:1 Snow Nab-stedt hydraulic reverse/reduction gear driving the main shaft with 16 'D'-section Goodyear vee belts. At each end of the five-part, 4-inch diameter main shaft is a Federal three-bladed 50 inch by 32 inch right-hand pro-peller. The propellers thus turn to-gether, one pushing and one pulling, until direction is reversed. Thrust is absorbed by two SKF roller thrust bearings amidships and the various sections of the shaft are joined by Link-Belt split-sleeve couplings with internal annular ring thrust keys. The main engine is fitted with a keel cooling system, using galvanized wrought-iron pipes welded to the ex-terior of the hull and circulated through an internal heat exchanger. Engine coolant is distilled water and anti-freeze. Ships power and lighting is 32-volt direct current, obtained from a bank of heavy-duty 203-anipere-hour Sur-rette batteries which are charged from either a Leece Neville alternator driv-en off the main engine, or one driven from the Lister LD2 auxiliary diesel. Distribution is arranged from an en-gine room board designed and built by Federal Pacific Electric Company. An Oceanic Electric Company's shore connection is provided for using shore power when not operating. Separate battery banks are provided for the Henschel general alarm, the emergen-cy lights, magnesyn compass system, and auxiliary engine starting. Com-munications between pilothouses and engine room are made through a sound-powered telephone system and ship-to-ship or ship-to-shore through an Apelco radio. Portable Light Com-pany searchlights are installed. All electric fittings were supplied by Oceanic Electric Company. The vessel's 600 gallons of fuel is divided between two tanks and sound-ings for these are indicated on the main deck level by Liquidometer Midget Levelmeter gauges. Several unique features incorpor-ated into the construction of the boat reflect the experience of her opera-tors and the peculiarities of the run. A small rotary blower is driven from the vee belt idler shaft and distributes the warm engine room air to the other underdeck compartments through a system of ductwork. This eliminates any condensation in these spaces by the circulation of air and is expected to result in a maintenance-free hull interior. An electrical magnesyn compass system using a master compass on an aluminum mast six feet above the deckhouse and repeaters in each pilot-house, remains free of deviation shown in the magnetic compasses due to the presence of large trucks and ir-regular disposition of magnetic loads. At each end, rolling aluminum-plate gates extend from the bulwark to keep the deck free of spray from the short choppy seas common to the run and also provide an additional meas-ure of safety for passengers and vehi-cles. In cold weather, cabin radiators are heated by hot water from a heat ex-changer on the engine cooling system. Since the engine is in continuous operation, heat is readily obtainable upon demand by use of Minneapolis-Honeywell heating controls. Each pilothouse is fitted out with intership phone, radio controls, special Kearfott aluminum-framed full drop windows, electric windshield wiper, engine and auxiliary engine controls, general-alarm contact makers and posi-tive action pedestal steerers with mechanism for automatically locking the bow rudder in center position. Features such as these, plus an all-out effort on the part of all parties involved in its creation, has resulted in a highly efficient vessel meeting the latest standards for passenger com-fort and safety and using the most up-to-date materials and methods ac-ceptable to the service. AMF Cuno Appoints MacCulloch Manager For Marine Sales William W. MacCulloch William W. MacCulloch has been appointed manager, marine sales, for the evaporator products group of the AMF Cuno Division, Ameri-can Machine & Foundry Company, Meriden, Conn., it was announced by Thomas S. Willets, general sales manager. In this capacity, Mr. MacCulloch will be responsible for the sale of the company's Maxim Thermoflash and Aquafresh Evaporators for service aboard merchant and naval vessels. Maxim marine evaporators are used in sizes up to 100,000 gpd aboard ships for converting seawa-ter into freshwater for potable use and boiler make-up feed. Before joining AMF Cuno, Mr. MacCulloch held the position of contracts administrator with the W. B. Arnold Company, Inc., of Hoboken, N.J. He was previously associated with Aqua-Chem, Inc. in a marine sales capacity and served in the merchant marine where he was licensed as second assistant engineer for both steam and diesel vessels. A 1960 graduate of the Massa-chusetts Maritime Academy with a bachelor's degree in marine and electrical engineering, Mr. MacCul-loch has also pursued studies in oceanology at the University of Miami and geology at Boston Uni-versity. C. Stone To Represent Walz & Krenzer, Inc. And Marine Products Carson Stone Walz & Krenzer, Inc. of Roches-ter, N.Y., and Marine Products & Engineering Co. of New York City, have announced the appointment of Carson Stone (Carstone Corpora-tion) as their Gulf area representa-tive. MP&E and W&K specialize in the design and manufacture of hy-draulic power and manual activated sliding watertight doors, sideports, ramps, bulkhead doors and Pilgrim propeller nuts. In addition to the main offices and plant, both companies jointly maintain branches in San Fran-cisco, San Pedro, Seattle, Vancou-ver and Montreal. THE ALCOA SEAPROBE, a trailblazing all-aluminum oceanographic vessel, will be one of the first major applications of new corrosion-resistant temper H1 17 developed by Aluminum Company of America. The new temper endows aluminum marine alloys 5456 and 5086 with virtual immunity to exfoliation corrosion. Scheduled to get under con-struction within a few months, the 2,000-ton displacement ship will require more than 500,000 pounds of aluminum alloy 5456-H117. Alcoa Seaprobe will have the ability to hold its position in rough seas; search, core, drill and sample mineral deposits on the ocean floor; locate and retrieve heavy objects more than a mile beneath the sur-face; and perform other exploratory oceanographic functions. 62 Maritime Reporter/Engineering News

59

59

61

61